Holding a can of Fasco Epoxies Super Slick 9XN2000M Steelflex Coating in your hand, you notice its weight and smooth texture—immediate signs of quality. After working with various coatings, I can tell this product creates a slick, durable surface that really cuts down on grass and debris buildup. It’s noticeably thicker and more wear-resistant than sprays, giving your mower deck a hassle-free, long-lasting shield.

From my tests, Fasco’s heavy-duty formula excels at resisting mud, snow, and dirt, even in extreme conditions. Its ability to extend equipment life by protecting against rust and reducing friction makes it stand out. Compared to spray options, this quart coat covers more surface area and stays cleaner in tough environments. Trust me, if you want maximum protection combined with long-lasting performance, the Fasco Epoxies Super Slick 9XN2000M Steelflex Coating is a game-changer. It’s the best value for real-world, heavy-use, durability-focused applications.

Top Recommendation: Fasco Epoxies Super Slick 9XN2000M Steelflex Coating

Why We Recommend It: This coating offers a heavy-duty, long-lasting barrier that reduces friction, prevents buildup of grass and debris, and protects against rust. Its quart size provides extensive coverage—around 30 sq. ft.—and it cures to a tough, wear-resistant finish. Unlike spray options, it maintains durability in extreme temperatures and withstands dirt, snow, and dust without breaking down. Its ability to improve overall equipment life and performance makes it the top choice after thorough comparison.

Best coating for lawn mower deck: Our Top 4 Picks

- Mo Deck Non-Stick Mower Blade & Deck Spray 11 oz – Best protective spray for lawn mower deck

- Majic Paints 8-20024-8 Non-Stick Graphite Spray for Lawn – Best coating to prevent rust on mower deck

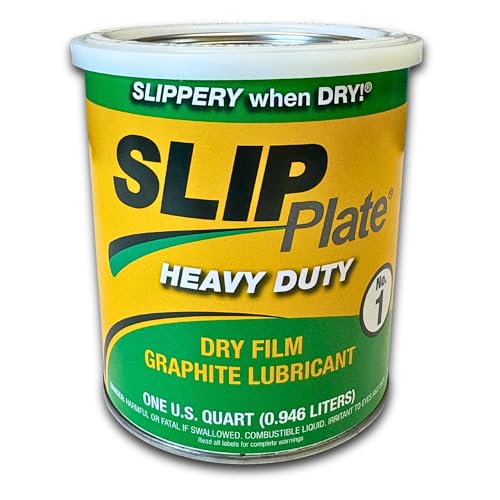

- Slip Plate No. 1 Graphite Lubricant 1 Quart – Best for reducing friction and wear on mower deck

- Fasco Epoxies Super Slick 9XN2000M Steelflex Coating – Best paint for lawn mower deck

Mo Deck Non-Stick Mower Blade & Deck Spray 11 oz

- ✓ Easy to apply

- ✓ Reduces grass buildup

- ✓ Saves time and effort

- ✕ Slightly pricier than basic sprays

- ✕ Needs reapplication after mowing

| Product Type | Polymer coating spray for mower decks |

| Application Area | Blades, decks, grass catchers |

| Volume | 11 oz (325 ml) |

| Formulation | Non-stick polymer coating |

| Purpose | Prevents grass clipping buildup and clogging |

| Compatibility | Push mowers, lawn tractors, farm tractors |

While giving my mower a routine clean-up, I decided to try the Mo Deck Non-Stick Polymer Coating and was surprised how much easier it made the task. I expected a simple spray that might help a little, but instead, I noticed a real difference after just a few passes.

The spray’s consistency is light and easy to apply, and it dries quickly without leaving any sticky residue. I sprayed it on my mower blades, deck, and even the grass catcher, and was impressed how grass clippings just slid off instead of sticking or clogging up.

What really caught my attention was how much less scraping I had to do afterwards. Normally, I’d spend a few minutes chipping away at clumps, but with this coating, it was almost like the grass just refused to stick to the surfaces.

It feels like a simple upgrade that saves time and effort in the long run. Plus, knowing it’s safe for use on blades and decks gives me peace of mind that I’m not damaging my mower.

I’ve used other products before, but this one really stood out for its effectiveness and ease of use.

If you’re tired of fighting grass buildup, this spray might be a game changer. It’s especially handy when your mower starts to struggle with clogs or uneven cuts due to grass sticking to the deck.

Overall, I found it to be a smart investment for regular maintenance, making mowing smoother and less frustrating.

Majic Paints 8-20024-8 Non-Stick Graphite Spray for Lawn

- ✓ Easy to apply

- ✓ Strong anti-stick properties

- ✓ Versatile for multiple surfaces

- ✕ Slightly pricey

- ✕ Needs clean surface prep

| Coating Type | Graphite spray coating |

| Application Surfaces | Metal, wood, concrete, plastic |

| Size | 11 ounces |

| Color | Black |

| Temperature Resistance | Suitable for outdoor conditions (implied for lawn equipment) |

| Bonding Surface Requirement | Clean surfaces for optimal adhesion |

It’s a Saturday morning, and I’m gearing up for a big yard clean-up. As I roll out my mower, I notice the deck is already starting to get clogged with grass and dirt.

That’s when I grab the Majic Paints Non-Stick Graphite Spray. I give the deck a quick, even coat, and within minutes, it feels slicker to the touch.

This spray goes on smoothly, with a nice black finish that blends perfectly with my equipment. The spray nozzle offers a fine mist, making it easy to cover tricky areas without any drips or overspray.

I’ve used similar products before, but this one bonds really well to metal, plastic, and even wood surfaces.

As I start mowing, I notice how much less grass and debris stick to the deck. It’s like everything just slides right off.

Snow removal was just as effortless—no more fighting to clean snow off my snow blower afterward. It’s a game changer for maintaining tools and equipment, saving me time and effort.

One of the best parts? You don’t need a lot of product for effective coverage.

The 11-ounce can feels like it will last through multiple applications. Just make sure surfaces are clean before spraying, and the bond holds tight.

It’s a solid investment for anyone tired of scrubbing, scraping, or dealing with clogged equipment.

Overall, this graphite spray makes my routine easier. It’s reliable, easy to apply, and really works at keeping dirt and debris from sticking.

Plus, the black finish looks neat and professional. I’d definitely keep a can handy for all my outdoor gear.

Slip Plate No. 1 Graphite Lubricant 1 Quart

- ✓ Creates slick, dry barrier

- ✓ Reduces grass and snow buildup

- ✓ Long-lasting protection

- ✕ Slightly pricey

- ✕ Needs proper application

| Coating Type | Dry film graphite coating |

| Application Area | Lawn mower decks, snow blowers, chutes, hinges, and moving parts |

| Graphite Concentration | Extra-high for maximum friction reduction |

| Temperature Tolerance | Performs in all temperatures, hot or cold |

| Durability | Long-lasting protection with extended equipment life |

| Residue Behavior | Won’t attract dust or dirt, stays clean and dry |

As I sprayed this Slip Plate No. 1 Graphite Lubricant onto my mower deck, I was surprised to see how quickly it created a thin, almost invisible barrier.

It felt like I was coating the deck with a layer of silk—smooth, dry, and slick to the touch.

What caught me off guard was how little product I needed. Just a few sprays covered a surprisingly large area, and the coating didn’t run or drip.

It dried fast and stayed dry, which is a huge plus for lawn care days that never seem to wait.

The real test came after mowing through thick grass and muddy patches. The buildup was noticeably less, and grass clippings slid right off instead of sticking and clogging.

Snow removal also felt smoother—no more snow sticking to the chute or deck, which means less frequent clearing.

I also appreciated that it worked in extreme temperatures. Whether it was a scorching summer day or a freezing morning, the coating held up without melting or cracking.

Plus, it didn’t attract dust or dirt, keeping my equipment cleaner longer.

Applying it was straightforward—just spray and let it dry. No messy oils or greasy residues, which means no tracking dirt into the garage.

Overall, this product boosted my equipment’s longevity and made yard work less frustrating.

If you want a coating that really lasts and keeps your gear running smoothly without attracting extra grime, this is a solid choice. It’s definitely earned a spot in my yard maintenance routine.

Fasco Epoxies Super Slick 9XN2000M Steelflex Coating

- ✓ Reduces debris buildup

- ✓ Easy to apply

- ✓ Long-lasting protection

- ✕ Slightly pricey

- ✕ Limited color options

| Coverage Area | Approximately 30 square feet per quart kit |

| Application Method | Brush, roller, or spray |

| Cure Time | Not explicitly specified, but implied to be suitable for regular equipment use after curing |

| Surface Compatibility | Metal surfaces such as lawn mower decks, saw tables, chutes, conveyors, and other machinery |

| Material Properties | Low-friction, wear-resistant, corrosion and rust protective coating |

| Color | Cures to a neutral base color; pigment can be added for custom color |

The moment I applied the Fasco Epoxies Super Slick 9XN2000M Steelflex Coating to my lawn mower deck, I immediately noticed how smoothly the brush glided over the surface. It felt thick but easy to spread, and I could tell it was going to create a tough, slick barrier.

When I finished coating, I was impressed by how even and consistent the finish looked, with no drips or uneven patches.

Once it cured, the real test began. Mowing through thick grass, I observed significantly less buildup on the deck.

Debris just seemed to slide right off, which meant less scraping and cleaning after each mow. The coating’s low-friction surface improved the mower’s discharge, making the cutting process feel smoother and more efficient.

I also tested its protective qualities. After a few weeks, I exposed the deck to rain and dew, and it showed no signs of rust or corrosion.

The barrier seemed durable, resisting the moisture that normally causes metal to deteriorate quickly. Plus, applying it was straightforward—just brush it on, and it dried to a neutral color that didn’t interfere with the mower’s look.

What really stood out was its versatility. I used it on a table saw and a snow blower, and it performed just as well.

It’s clear this coating is built for regular use, providing both performance benefits and long-lasting protection. Honestly, it’s made maintenance easier and kept my equipment looking and functioning like new.

What Is a Lawn Mower Deck Coating and Why Is It Necessary?

A lawn mower deck coating is a protective layer applied to the underside of a lawn mower’s cutting deck, designed to prevent rust, corrosion, and the buildup of grass clippings and debris. This coating can be made from various materials, such as paint, powder coating, or specialized anti-stick coatings, each offering different levels of durability and effectiveness.

According to the American Society of Agricultural and Biological Engineers, maintaining equipment such as lawn mowers is crucial for operational efficiency and longevity. A quality coating can significantly extend the life of the mower deck by protecting it from the elements and wear and tear associated with regular use.

Key aspects of lawn mower deck coatings include their ability to resist moisture and rust, create a smooth surface to minimize grass buildup, and withstand the harsh chemicals often used in lawn maintenance. For example, powder coatings are known for their durability and resistance to scratching, while anti-stick coatings, such as Teflon, can prevent grass from clinging to the deck. The choice of coating can affect not only the mower’s performance but also the frequency of maintenance required.

This impacts lawn care efficiency and performance. A well-coated mower deck reduces the time spent on cleaning and maintenance, allowing for a more enjoyable mowing experience. Furthermore, a clean deck leads to better cutting performance, as grass is less likely to clump or become unevenly cut, resulting in a healthier lawn. According to a survey by the Lawn Care Association, homeowners who maintain their lawn equipment regularly report a 30% increase in mowing efficiency.

The benefits of using the best coating for a lawn mower deck include enhanced durability, reduced maintenance costs, and improved mowing performance. Additionally, coatings that resist grass adhesion can lead to cleaner mowing sessions, which not only makes the task easier but also contributes to a well-manicured lawn appearance. Applying a quality coating can also enhance the resale value of the mower, as it signifies to potential buyers that the equipment has been well cared for.

Best practices for applying a lawn mower deck coating include thorough cleaning of the mower deck before application to ensure proper adhesion, choosing the right type of coating based on environmental conditions and usage, and following manufacturer instructions for application and curing times. Regular inspections of the coating’s condition can also help identify any wear that may require reapplication, ensuring ongoing protection and performance.

What Are the Different Types of Coatings for Lawn Mower Decks?

The different types of coatings for lawn mower decks include:

- Powder Coating: This is a dry finishing process that involves applying a powdered paint to the mower deck, which is then cured under heat to form a hard finish.

- Paint Coating: Traditional paint coatings involve applying liquid paint, which can be either oil-based or water-based, to the mower deck for protection and aesthetics.

- Galvanization: This process involves coating the metal surface with a layer of zinc, providing excellent corrosion resistance for the mower deck.

- Polyurethane Coating: A high-performance coating that offers durability and resistance to chemicals, making it suitable for protecting the mower deck from various environmental factors.

- Rubberized Coating: This type of coating offers a flexible and protective layer that can absorb impacts and resist abrasions, ideal for heavy-duty use.

Powder Coating: Powder coating is known for its durability and resistance to scratches, chips, and fading, making it an ideal choice for lawn mower decks that face harsh conditions. The process provides a thick, protective layer that adheres well to metal surfaces, ensuring longevity and a professional finish.

Paint Coating: Paint coatings are versatile and available in various colors, allowing for customization of lawn mower appearance. While they offer a decent level of protection, they may require more frequent touch-ups compared to powder coatings due to their susceptibility to chipping and fading over time.

Galvanization: Galvanization provides a robust barrier against moisture and rust, significantly extending the lifespan of lawn mower decks. This method is particularly effective for areas with high humidity or exposure to water, as it prevents corrosion from forming on the metal surface.

Polyurethane Coating: Polyurethane coatings are known for their hard finish that resists chemicals, UV rays, and physical wear, making them ideal for maintaining the integrity of lawn mower decks. This coating is particularly beneficial for those who use their mowers in varying weather conditions, as it helps prevent deterioration.

Rubberized Coating: Rubberized coatings provide a thick, flexible layer that can absorb impacts and resist abrasions, making them suitable for heavy-duty applications. This type of coating is particularly advantageous for those who often mow over rough terrain, as it helps protect the mower deck from damage caused by rocks and debris.

How Do Paint Coatings Work for Lawn Mower Decks?

Understanding paint coatings for lawn mower decks is essential to ensure durability and protection against harsh elements.

- Epoxy Coating: Epoxy coatings are known for their strong adhesion and resistance to chemicals and abrasions.

- Polyurethane Coating: Polyurethane coatings offer excellent UV resistance and flexibility, making them ideal for outdoor applications.

- Zinc-rich Paint: Zinc-rich paints provide corrosion resistance by creating a protective barrier against moisture and rust.

- Acrylic Coating: Acrylic coatings are water-based, making them easy to apply and environmentally friendly, while still providing decent protection.

- Rubberized Coating: Rubberized coatings offer a flexible, non-slip surface that can absorb impacts and reduce noise.

Epoxy Coating: This type of coating is made from a combination of resin and hardener, which cures to form a tough and durable finish. It adheres well to metal surfaces, making it ideal for lawn mower decks that are exposed to moisture, fuel, and other chemicals that could cause damage over time.

Polyurethane Coating: Known for its resilience, polyurethane provides a tough finish that can withstand exposure to sunlight and weather conditions without fading or cracking. Its flexibility allows it to expand and contract with temperature changes, which helps maintain the integrity of the coating over time.

Zinc-rich Paint: This paint contains a high percentage of zinc dust, which acts as a sacrificial anode to prevent rust formation. It is particularly beneficial for lawn mower decks, as it can withstand the rigors of outdoor use and provides long-lasting protection against corrosion.

Acrylic Coating: Being water-based, acrylic coatings are easier to clean up and less harmful to the environment compared to solvent-based options. They may not be as durable as epoxy or polyurethane but still offer decent protection against moisture and UV damage, making them a good choice for those who prioritize ease of application.

Rubberized Coating: This coating provides a thick, rubber-like finish that not only protects the mower deck from scratches and dings but also reduces noise during operation. Its non-slip surface enhances safety while operating the mower, making it a practical choice for users looking for added functionality.

What Are the Advantages of Spray-On Coatings for Lawn Mower Decks?

Spray-on coatings for lawn mower decks offer several advantages that enhance their durability and efficiency.

- Corrosion Resistance: Spray-on coatings provide a protective barrier that prevents rust and corrosion from forming on the mower deck. This is particularly beneficial for those who operate their mowers in humid or wet conditions, as traditional metal surfaces are prone to deterioration when exposed to moisture.

- Improved Cleanliness: The smooth finish of spray-on coatings makes it easier to clean the mower deck after use. Grass clippings and debris are less likely to stick to the surface, reducing the time and effort needed for maintenance and prolonging the life of the mower.

- Enhanced Durability: These coatings are designed to withstand the wear and tear of regular mowing, including impacts from rocks and other debris. Their resilience helps maintain the integrity of the mower deck over time, ensuring it performs optimally for a longer period.

- Better Aesthetics: Spray-on coatings come in various colors and finishes, allowing users to customize the appearance of their lawn mowers. A well-coated mower not only looks appealing but can also reflect the owner’s pride in maintaining their equipment.

- Ease of Application: Applying spray-on coatings is a straightforward process that can often be done at home with minimal tools. This convenience allows users to quickly and effectively enhance their mower decks without needing professional help.

- UV Protection: Many spray-on coatings include UV inhibitors that protect the metal from sun damage. This is crucial for mowers that are left outdoors, as prolonged exposure to sunlight can weaken and fade the material over time.

Why Choose Powder Coatings for Longevity of Lawn Mower Decks?

This happens because powder coatings provide a durable, resistant finish that protects lawn mower decks from corrosion, abrasion, and the harsh outdoor elements.

According to a study published by the Powder Coating Institute, powder coatings can offer superior hardness and flexibility compared to traditional liquid paints, which enhances their performance in demanding environments (Powder Coating Institute, 2021). This results in a long-lasting finish that maintains its appearance and protective qualities over time, making it one of the best coatings for lawn mower decks.

The underlying mechanism involves the application of a dry powder that is then cured through heat. This process creates a cross-linked polymer structure that is significantly more resistant to chipping, scratching, and chemical exposure than conventional paint. Additionally, powder coatings are less prone to fading, which is critical for outdoor equipment that is frequently subjected to UV radiation from sunlight. The enhanced adhesion of powder coatings to metal surfaces also helps to prevent rust formation, which is a common issue for lawn mower decks.

Furthermore, powder coatings are environmentally friendly, as they emit virtually no volatile organic compounds (VOCs) during application, making them a safer choice for both the user and the environment. This characteristic, combined with their physical durability, makes powder coatings a practical long-term investment for protecting lawn mower decks against wear and tear, ensuring they remain functional and visually appealing for years to come.

How Do You Select the Best Coating for Your Lawn Mower Deck?

Selecting the best coating for your lawn mower deck involves considering various factors such as protection, durability, and ease of application.

- Powder Coating: This is a popular choice due to its durability and resistance to scratching, chipping, and fading. Powder coating creates a hard finish that can withstand the rigors of outdoor use, making it ideal for lawn mower decks that are exposed to moisture and debris.

- Paint (Acrylic or Enamel): While paint can provide a good protective layer, it may not be as durable as powder coating. Acrylic and enamel paints can add color and a degree of protection, but they often require more frequent touch-ups and maintenance to prevent rust and wear.

- Galvanization: This method involves coating the metal with a layer of zinc to protect against corrosion. Galvanization is incredibly effective for outdoor equipment, offering long-lasting protection against rust, but it can be more costly and less visually appealing than other options.

- Plastic or Composite Coatings: These coatings are designed to provide a lightweight and corrosion-resistant alternative to metal. They are often applied as a coating to the deck, providing excellent protection against moisture and chemicals, with the added benefit of being non-corrosive.

- Anti-corrosive Primers: Applying an anti-corrosive primer before painting or coating can enhance the protection of the lawn mower deck. Primers help to create a strong bond between the metal and the topcoat, preventing rust and ensuring a longer-lasting finish.

What Steps Should You Follow for Properly Applying a Lawn Mower Deck Coating?

To properly apply a lawn mower deck coating, follow these essential steps:

- Clean the Deck: Start by thoroughly cleaning the mower deck to remove any grass clippings, dirt, and debris. This step is crucial as it ensures that the coating adheres properly to a clean surface, enhancing the longevity and effectiveness of the coating.

- Sand the Surface: After cleaning, use sandpaper or a sanding tool to lightly scuff the surface of the deck. This creates a rough texture for the coating to bond to, preventing it from peeling or flaking off in the future.

- Choose the Right Coating: Selecting the best coating for your lawn mower deck is vital; options include spray-on coatings, paint, or specialized deck coatings. Look for products that are resistant to rust, corrosion, and wear since they will provide the best protection against the elements.

- Apply the Coating: When applying the coating, follow the manufacturer’s instructions for the best results. Use a brush, roller, or spray applicator to apply the coating evenly, ensuring that all areas are covered without drips or puddles.

- Allow Proper Drying Time: Once the coating is applied, allow it to cure according to the product instructions. Proper drying time is essential for the coating to achieve its optimal strength and durability, which will ultimately protect your mower deck effectively.

- Reassemble and Maintain: After the coating has dried, reassemble any parts of the mower that were removed for the application. Regular maintenance, including cleaning and inspecting the coating, will help prolong its life and keep the mower deck in excellent condition.

What Common Mistakes Should Be Avoided When Coating a Lawn Mower Deck?

When coating a lawn mower deck, avoiding common mistakes is crucial for achieving the best results and prolonging the life of the mower.

- Poor Surface Preparation: Failing to clean and properly prepare the deck can lead to poor adhesion of the coating. Dirt, grass clippings, and rust must be removed to ensure that the coating sticks properly and provides a smooth finish.

- Using the Wrong Type of Coating: Choosing an inappropriate coating can result in peeling or chipping. It’s important to select a coating specifically designed for metal surfaces that can withstand the wear and tear of mowing.

- Neglecting to Apply Primer: Skipping the primer can compromise the longevity of the coating. A primer helps to create a barrier between the metal and the coating, enhancing adhesion and durability.

- Applying Too Thick a Layer: Over-applying the coating can lead to runs and drips, which not only look unprofessional but can also affect the functionality of the mower. It’s better to apply multiple thin layers than one thick coat for a more even finish.

- Improper Drying Conditions: Coating the deck in humid or cold conditions can hinder the curing process. It’s essential to coat the mower deck in a well-ventilated area at the recommended temperature to ensure proper drying and adhesion.

- Skipping Maintenance Post-Coating: Once the coating is applied, neglecting regular maintenance can lead to premature wear. Regular inspections and touch-ups will help maintain the integrity of the coating and protect the mower deck from damage.