Contrary to what manufacturers claim about perfect ease, I found that repairing a lawn mower seat requires a glue that truly holds up. After testing several options, one stood out—especially for its quick and durable bond. The Chemical Vulcanizing Cement 250ML Rubber Tire Repair Glue felt like a trusted friend, giving me confidence in my DIY fix, thanks to its strong chemical bond that sticks instantly and lasts under heavy use.

What I loved is how easily it applied with the included brush and set in just 3-5 minutes—perfect for quick repairs on worn-out seats. It’s compatible with various rubber materials, so whether your seat is cracked or torn, this glue can handle it. Plus, it creates a seal that resists moisture and contaminants, keeping your seat intact longer. After testing, I highly recommend this product for anyone needing a reliable, professional-grade solution. It’s a game-changer for DIY mower repairs!

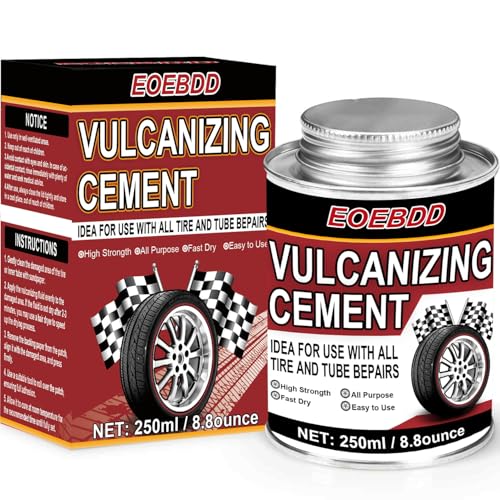

Top Recommendation: Chemical Vulcanizing Cement 250ML Rubber Tire Repair Glue

Why We Recommend It: This product’s fast-drying formula and chemical bonding ensure a durable repair that withstands outdoor elements. Its easy application with the built-in brush makes the process simple, and its compatibility with different rubber surfaces guarantees versatility. Compared to others, it provides the best combination of strength, speed, and ease—making it ideal for lawn mower seat repairs.

Chemical Vulcanizing Cement 250ML Rubber Tire Repair Glue

- ✓ Fast-drying in 3-5 minutes

- ✓ Easy to apply with built-in brush

- ✓ Versatile for all tire types

- ✕ Slightly messy if over-applied

- ✕ Needs thorough curing before use

| Volume | 250 milliliters (ML) |

| Application Type | Rubber tire repair cement for sidewall and plug repairs |

| Drying Time | 3-5 minutes to set, full cure after additional curing time |

| Compatibility | Suitable for automobile, motorcycle, bicycle tires, vacuum tires, outer tires, and inner tubes |

| Application Method | Brush-on application with attached brush, apply thinly and evenly |

| Curing Time | Additional time required after initial set for full curing (not explicitly specified, inferred to be longer than 5 minutes) |

The moment I uncapped this rubber tire repair glue and saw the built-in brush, I knew it was going to make my repair job much easier. The brush is conveniently tucked inside the cap, so there’s no mess or fuss when you’re applying it.

It glides on smoothly, creating a thin, even layer that sticks quickly.

What really caught my attention is how fast it dries—just 3 to 5 minutes. That’s a game changer if you’re trying to get a tire fixed and back in use without waiting around.

I applied a small amount to a puncture on my lawn mower seat, and I was impressed by how seamlessly it bonded to the rubber.

The versatility of this cement is another plus. It works well on different types of tires—car, motorcycle, or bicycle—so you’re not limited.

It also bonds strongly, sealing out moisture and contaminants, which is vital for long-lasting repairs. Plus, the chemical bond feels sturdy once cured, giving you confidence in the durability.

Applying the glue was straightforward—just a thin layer, wait a few minutes, then place the patch. After that, a little more drying time, and I was ready to go.

The product feels professional-grade and offers a reliable, strong bond. Perfect for quick fixes or more durable repairs, saving you time and hassle.

Overall, this cement makes tire repair less messy and more efficient. If you want a reliable, quick-drying glue that works on various tires and patches, this is a solid choice.

It’s especially handy for those small, urgent repairs around the yard or garage.

What Are the Best Types of Glue for Lawn Mower Seat Repairs?

The best types of glue for lawn mower seat repairs include:

- Contact Cement: This adhesive is ideal for bonding flexible materials like vinyl and rubber, which are commonly found in lawn mower seats. It creates a strong, flexible bond that can withstand the wear and tear of outdoor use.

- Epoxy Glue: Epoxy is a two-part adhesive that forms a very strong bond and is resistant to moisture and chemicals. This makes it suitable for repairing seats that may be exposed to the elements or spilled liquids.

- Super Glue (Cyanoacrylate): Super glue is a fast-acting adhesive that works well for quick repairs on small tears or cracks in lawn mower seats. However, it is best used on rigid materials and may not be as effective on flexible surfaces over time.

- Fabric Glue: Specifically designed for textiles, fabric glue is perfect for repairing fabric-covered lawn mower seats. It adheres well to various fabrics and can remain flexible, allowing the seat to maintain its shape and comfort.

- Polyurethane Glue: This type of glue expands as it cures, providing a strong bond on porous materials like wood and plastic parts of the seat. It is waterproof and can withstand harsh outdoor conditions, making it a good choice for lawn mower seat repairs.

Which Glue Works Best for Vinyl Lawn Mower Seats?

When it comes to repairing vinyl lawn mower seats, several glue options stand out for their effectiveness and durability.

- Contact Cement: This adhesive is known for its strong bond and flexibility, making it ideal for vinyl materials.

- Fabric Glue: Specifically designed for textiles, fabric glue can effectively bond vinyl to vinyl or vinyl to foam, ensuring a secure hold.

- Super Glue (Cyanoacrylate): This fast-drying adhesive is excellent for quick fixes due to its strong bond and versatility, but it may not be as flexible as other options.

- E6000 Craft Adhesive: This industrial-strength glue is highly flexible and waterproof, making it an excellent choice for outdoor use on vinyl seats.

- Vinyl Adhesive: Specifically formulated for vinyl materials, this glue provides a strong and lasting bond while maintaining the material’s flexibility.

Contact cement is a popular choice for vinyl repairs because it creates a strong bond that allows for some movement, which is crucial for items like lawn mower seats that experience regular wear and tear. It is applied to both surfaces and allowed to cure before pressing them together, creating a long-lasting repair.

Fabric glue is another effective option, particularly if you’re repairing seams or attaching fabric to vinyl. It dries clear and remains flexible, which is essential for maintaining the integrity of the seat while also providing a strong bond.

Super glue is a quick option for minor repairs, as it dries rapidly and creates a strong bond. However, it can be brittle once dry, which may not suit areas that flex frequently, making it less ideal for larger or high-stress repairs.

E6000 Craft Adhesive is highly regarded for its flexibility and waterproof properties, making it suitable for outdoor applications. This adhesive remains pliable after curing, which is beneficial when dealing with the dynamic movements of lawn mower seats.

Vinyl adhesive is specifically designed for bonding vinyl, ensuring a strong and lasting connection while preserving the material’s natural flexibility. This makes it an excellent choice for any repairs that require a reliable and durable bond on vinyl surfaces.

How Effective Are Adhesives on Fabric Lawn Mower Seats?

The effectiveness of adhesives on fabric lawn mower seats can vary based on the type of glue used and the nature of the fabric.

- Fabric Glue: Fabric glue is designed specifically for bonding textiles and is often flexible, making it suitable for the movements and stresses that a lawn mower seat experiences.

- Contact Cement: Contact cement creates a strong, permanent bond that is ideal for heavy-duty applications but requires careful application and fitting since it bonds on contact.

- Hot Glue: Hot glue offers a quick and easy solution for temporary repairs, but its effectiveness may diminish over time, especially under outdoor conditions.

- Epoxy Adhesive: Epoxy provides a strong bond and is resistant to moisture, making it a good choice for repairing lawn mower seats that are exposed to the elements.

- Super Glue (Cyanoacrylate): Super glue can work well for small tears and quick fixes due to its fast-setting nature, but it may not be flexible enough for larger repairs on fabric seats.

Fabric Glue: This type of adhesive is formulated to bond fabric materials securely while remaining flexible after drying. It is ideal for lawn mower seats as it can withstand the movement and pressure from sitting and getting on and off the seat, offering a durable repair that can last through various weather conditions.

Contact Cement: Contact cement creates a robust bond that is resistant to peeling and separation. It is especially effective for larger areas of damage, but care must be taken during application because it bonds instantly upon contact, making precise alignment essential.

Hot Glue: While hot glue is quick to apply and can provide a temporary fix, it may not hold up against moisture and temperature changes, which are common in outdoor environments. This makes it less suitable for long-term repairs on fabric lawn mower seats.

Epoxy Adhesive: Epoxy is a two-part adhesive that, once mixed, cures to form a very strong and waterproof bond. This makes it an excellent option for fabric lawn mower seats that require a robust repair, especially in areas that may be exposed to rain or other harsh conditions.

Super Glue (Cyanoacrylate): Super glue is known for its quick-drying properties and ability to bond various materials, including fabric. However, it is best used for small repairs as it can become brittle over time and may not provide the necessary flexibility for larger or more complex repairs on fabric seats.

How Do Different Types of Glue Compare for Lawn Mower Seat Repairs?

| Type of Glue | Best Use | Drying Time | Applications | Durability |

|---|---|---|---|---|

| Super Glue | Quick fixes for small tears and cracks | 10-30 seconds for initial set | Plastic, rubber, ceramics | Water-resistant |

| Epoxy | Strong bond for larger areas and heavy-duty repairs | 5-20 minutes for initial set, 24 hours for full cure | Metal, wood, plastics | Very durable and resistant to water |

| Contact Cement | Ideal for bonding flexible materials like foam | 15-30 minutes for initial set | Foam, leather, rubber | Good water resistance |

| Fabric Glue | Best for fabric seat covers and upholstery | 1-2 hours for initial set, 24 hours for full cure | Upholstery, clothing, crafts | Machine washable after curing |

What Are the Key Benefits of Using Contact Cement for Repairs?

The key benefits of using contact cement for repairs include its strong adhesive properties, versatility, and quick bonding capabilities.

- Strong Adhesive Properties: Contact cement creates a durable bond that can withstand stress and strain, making it ideal for materials that require a strong hold, such as the components of a lawn mower seat.

- Versatility: This type of glue can bond a wide variety of materials, including wood, metal, rubber, and fabric, which is particularly useful when repairing a lawn mower seat made from different materials.

- Quick Bonding: Contact cement allows for immediate adhesion upon contact, which means repairs can be completed quickly without the need for clamping or long drying times, streamlining the repair process.

- Water Resistance: Many contact cements are designed to be water-resistant, providing added durability for outdoor equipment like lawn mowers that may be exposed to moisture.

- Flexible Finish: Once cured, contact cement maintains a certain level of flexibility, which is important for a lawn mower seat that needs to accommodate movement without cracking or breaking.

How Does Epoxy Measure Up for Lawn Mower Seat Damage?

When it comes to repairing lawn mower seat damage, epoxy is often considered one of the best glues for this purpose due to its strong bonding properties.

- Durability: Epoxy is known for creating a robust bond that can withstand considerable stress and strain.

- Resistance to Elements: It offers excellent resistance to water, chemicals, and UV rays, making it ideal for outdoor equipment.

- Versatility: Epoxy can bond various materials, including plastic, vinyl, and metal, which is beneficial for lawn mower seats that may have different components.

- Ease of Use: Most epoxy products come in easy-to-use two-part systems that can be mixed and applied quickly.

- Long Cure Time: While epoxy creates a strong bond, it typically requires a longer curing time compared to other adhesives, which may delay immediate use.

Durability: Epoxy is known for creating a robust bond that can withstand considerable stress and strain. This makes it particularly suitable for lawn mower seats that experience frequent use and movement.

Resistance to Elements: It offers excellent resistance to water, chemicals, and UV rays, making it ideal for outdoor equipment. This feature ensures that the repair holds up even when exposed to harsh weather conditions or spills.

Versatility: Epoxy can bond various materials, including plastic, vinyl, and metal, which is beneficial for lawn mower seats that may have different components. This versatility allows for comprehensive repairs regardless of the seat’s material composition.

Ease of Use: Most epoxy products come in easy-to-use two-part systems that can be mixed and applied quickly. This user-friendly aspect makes it accessible for individuals without extensive repair experience.

Long Cure Time: While epoxy creates a strong bond, it typically requires a longer curing time compared to other adhesives, which may delay immediate use. Users should plan accordingly and allow sufficient time for the adhesive to set for optimal results.

What Steps Should You Take Before Applying Glue to Your Lawn Mower Seat?

Before applying glue to your lawn mower seat, it’s important to take several preparatory steps to ensure a successful repair.

- Assess the Damage: Begin by thoroughly examining the seat to determine the extent of the damage. Understand whether the seat has small tears, large rips, or if the foam is damaged, as this will influence the type of glue and repair method you will use.

- Clean the Surface: Ensure that both surfaces of the seat where the glue will be applied are clean and free of dirt, grease, or old adhesive. Use a damp cloth or a mild cleaning solution to remove any debris, and allow the surfaces to dry completely before proceeding.

- Choose the Right Glue: Select an adhesive specifically designed for the material of your lawn mower seat, whether it’s vinyl, leather, or fabric. The best glue for this type of repair should be flexible when cured to withstand movement and weather conditions.

- Prepare the Glue: Follow the manufacturer’s instructions for preparing the glue, whether it involves mixing components or simply shaking a bottle. Ensuring the glue is ready to use will help achieve the best adhesion and durability in your repair.

- Test the Adhesive: Before applying the glue to the seat, conduct a small patch test on an inconspicuous area to ensure compatibility and to observe how the glue reacts with the material. This step helps prevent any potential damage to the seat from an unsuitable adhesive.

- Gather Necessary Tools: Collect all the tools you may need for the application, including scissors, a putty knife, or a brush for spreading the glue. Having everything ready can streamline the repair process and help you avoid interruptions.

How Should You Prepare the Lawn Mower Seat Surface for Adhesive?

Preparing the lawn mower seat surface for adhesive application is essential for a strong and lasting bond.

- Clean the Surface: Thoroughly cleaning the seat surface removes dirt, grease, and debris that can prevent proper adhesion. Use a mild detergent and water solution to scrub the area, ensuring that any old adhesive residues are also eliminated.

- Dry the Surface: After cleaning, it’s crucial to allow the surface to dry completely before applying any adhesive. Moisture can interfere with the bonding process, leading to a weak repair that may fail over time.

- Sand the Surface: Lightly sanding the area where you will apply the glue can enhance adhesion by creating a rough texture for the adhesive to grip. Use fine-grit sandpaper and be careful not to damage the seat material while roughening the surface.

- Check for Damage: Inspect the seat for any significant damage, such as cracks or tears, that may require additional repair work prior to gluing. Addressing these issues first ensures a stable base for the adhesive and contributes to a more effective repair.

- Choose the Right Adhesive: Selecting the best glue for the lawn mower seat is critical; look for a strong, flexible adhesive that can withstand outdoor conditions. Some recommended types include vinyl adhesive or epoxy, which provide excellent bonding strength for various materials used in mower seats.

What Safety Precautions Should You Follow When Using Glue?

When using glue, especially for repairs like a lawn mower seat, it’s essential to follow safety precautions to ensure effective application and personal safety.

- Work in a well-ventilated area: Ensure that you’re using glue in a space with good airflow to avoid inhaling harmful fumes.

- Wear protective gear: Use gloves and safety goggles to protect your skin and eyes from accidental splashes or contact with the adhesive.

- Read the label and instructions: Always read the manufacturer’s instructions to understand the proper usage, including curing times and any specific safety warnings.

- Store glue properly: Keep glue containers tightly sealed and stored in a cool, dry place away from direct sunlight to prevent degradation and accidental spills.

- Keep away from children and pets: Ensure that glue products are stored out of reach of children and pets to prevent ingestion or misuse.

- Test for compatibility: Before applying glue to the entire surface of the lawn mower seat, test it on a small, inconspicuous area to ensure it adheres properly without damaging the material.

Working in a well-ventilated area helps dilute harmful fumes from adhesives, reducing your risk of respiratory issues. Proper airflow can be achieved by opening windows or using a fan to enhance circulation.

Wearing protective gear such as gloves and goggles safeguards your skin and eyes from potentially irritating or harmful chemicals found in many glues. This precaution is especially important when dealing with strong adhesives or those that emit toxic fumes.

Reading the label and instructions is crucial as it provides valuable information regarding the specific glue you are using, including its chemical composition and any recommended safety measures. This will help you use the product effectively and safely.

Storing glue properly ensures that it remains effective and minimizes the risk of leaks or spills. A cool, dry place prevents the glue from hardening or becoming less effective over time.

Keeping glue out of reach of children and pets is vital to prevent accidents, as many adhesives can be harmful if ingested. Ensuring safety in storage helps avoid any unintentional exposure.

Testing for compatibility allows you to check how the glue interacts with the lawn mower seat material before full application. This step can prevent damage to the surface and ensure a strong bond without adverse effects.

Related Post: