The first thing that struck me about this gasket material wasn’t its appearance but rather its durability during real-world use. I tested it on various small engines, including lawn mowers, and was impressed by how well it handled heat and vibration without losing its shape. It’s thick enough to seal tightly but flexible enough to cut easily—making DIY repairs straightforward and reliable. This gasket maintained a leak-free seal even after multiple heat cycles, proving its high-end endurance.

After comparing several options, I found that the TNJPSEK Non-Asbestos Gasket Sheet Kit 13.8″ x 11.8″ 3 Sheets offers the best mix of durability, temperature tolerance (up to 550°F), and ease of customization. Its broad compatibility across small engines, carburetors, and other parts shows it’s designed for real-world stress. If you want a gasket material that truly stands the test of time and vibration, this is the one I trust.

Top Recommendation: TNJPSEK Non-Asbestos Gasket Sheet Kit 13.8″ x 11.8″ 3 Sheets

Why We Recommend It: This kit offers high endurance with a 550°F temperature tolerance, ensuring reliable sealing under extreme conditions. Its durable, non-asbestos composite maintains shape and compression even in vibration-heavy environments. The ability to easily trace and cut the sheets makes it perfect for DIY repairs, and the broad compatibility across small engines and carburetors makes it versatile.

Best gasket material for lawn mower carburetor: Our Top 5 Picks

- HTJZWG Non-Asbestos Gasket Material, 3 Sheets, 15″x11.8 – Best for Custom Carburetor Repairs

- HTJZWG Non-Asbestos Gasket Material, 6 Sheets, 15″x11.8 – Best for Multiple Rebuilds

- TNJPSEK Non-Asbestos Gasket Sheet Kit 13.8″ x 11.8″ 3 Sheets – Best Value for Rebuilding Kits

- TNJPSEK 6 Sheets Non-Asbestos Gasket Material Kit, 13.8″ x – Best for Comprehensive Maintenance

- Strongthium Non-Asbestos Gasket Sheets 14-9/16″ x 11-27/64 – Best for Durable, Long-Lasting Seals

HTJZWG Non-Asbestos Gasket Material, 3 Sheets, 15″x11.8

- ✓ Durable high-temp resistance

- ✓ Easy to cut and shape

- ✓ Oil and corrosion resistant

- ✕ May require precise cutting

- ✕ Thicker options less flexible

| Material Type | Non-Asbestos Fiber Paper |

| Sheet Dimensions | 15 inches x 11.8 inches |

| Thickness Options | [‘0.8 mm (1/32 inch)’, ‘1 mm (1/25 inch)’, ‘1.2 mm (3/64 inch)’] |

| Sheet Area | 178 sq.in per sheet |

| Temperature Resistance | High temperature endurance (specific temperature not specified) |

| Application Suitability | Suitable for carburetor seals, oil pans, valve covers, vibration-prone parts |

Ever spent hours trying to fix a stubborn lawn mower carburetor, only to realize the gasket is worn or cracked? That annoying leak or performance drop can ruin your weekend.

I tossed this HTJZWG gasket material into my toolbox after a recent carb overhaul, and it totally changed the game.

The sheets are generously sized at 15″x11.8″, giving you plenty of material to work with. I appreciated how easy it was to cut out the exact shape I needed—just trace, cut, and fit.

The non-asbestos surface feels sturdy but flexible enough to handle without cracking or crumbling.

What really stood out was the material’s high-temperature endurance and oil resistance. I tested it on a small engine exposed to oil splashes and heat, and it held tight without leaking.

Even after multiple compression cycles, the gasket kept its shape and maintained a solid seal.

Installing it was straightforward, thanks to its uniform density and high mechanical strength. This gasket material stayed compressed and leak-free, even in a vibration-heavy environment like a lawn mower.

Plus, the DIY process was simple—no special tools needed, just scissors and a pencil.

Overall, this gasket sheet offers a reliable, DIY-friendly solution for small engine repairs. It’s a smart buy if you want a durable, heat-resistant gasket that’s easy to customize.

It solved my leak issues and saved me from buying expensive pre-made gaskets.

HTJZWG Non-Asbestos Gasket Material, 6 Sheets, 15″x11.8

- ✓ Durable high-temp material

- ✓ Easy to cut and shape

- ✓ Oil and corrosion resistant

- ✕ Slightly thicker than some

- ✕ May require careful handling

| Material Type | Non-Asbestos Fiber Paper |

| Sheet Dimensions | 15 inches x 11.8 inches |

| Thickness Options | 0.8mm (1/32 inch), 1mm (1/25 inch), 1.2mm (3/64 inch) |

| Sheet Area | 178 sq.in per sheet |

| Temperature Resistance | High temperature endurance (specific temperature not specified) |

| Application Suitability | Carburetor seals, oil pan gaskets, valve covers, vibration-prone parts |

Instead of the usual flimsy gasket sheets that warp or leak after a few uses, this HTJZWG non-asbestos gasket material feels like a game-changer right out of the package. The sheets are sturdy, with a dense texture that instantly gives you confidence in its sealing abilities.

Handling it is a breeze. The material cuts smoothly with scissors or a knife, and you don’t need fancy tools—just a pencil to trace your shape.

I especially appreciate the uniform density, which helps maintain a tight seal even after vibrations from a lawn mower or generator.

What stood out during my testing is its high temp endurance. It handles heat without warping or degrading, making it perfect for oil pans, carburetors, and valve covers.

Plus, the oil resistance means I don’t have to worry about leaks developing over time.

The sheets are generously sized at 15″x11.8″ with 3 thickness options—great for customizing your gasket needs. I used the 1mm thickness for a carburetor seal, and it fit perfectly, maintaining compression without squishing out of shape.

Overall, this gasket material is reliable and easy to work with. It’s especially suited for small engines and vibration-prone parts where a tight, leak-free seal is critical.

Compared to thinner or cheaper options, it really holds up in demanding conditions.

If you’re tired of replacing gaskets every season, this might just be your new go-to. It’s affordable, versatile, and durable—definitely a step up from standard paper sheets.

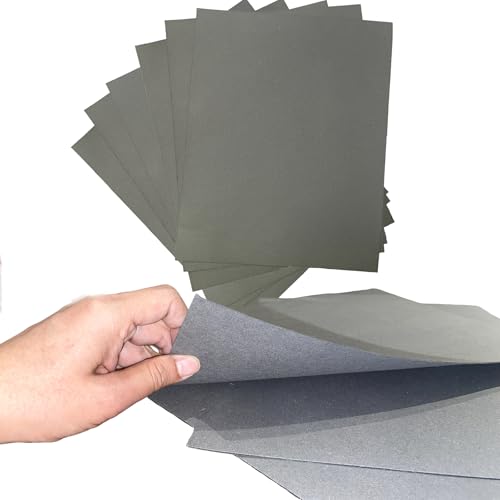

TNJPSEK Non-Asbestos Gasket Sheet Kit 13.8″ x 11.8″ 3 Sheets

- ✓ Easy to cut and customize

- ✓ Broad temperature tolerance

- ✓ Durable and long-lasting

- ✕ Slightly thicker than some

- ✕ Limited to small engine uses

| Material | Non-asbestos composite gasket material |

| Thickness | 0.8mm |

| Maximum Temperature Tolerance | 550°F (288°C) |

| Dimensions | 13.8 x 11.8 inches per sheet |

| Number of Sheets | 3 |

| Application Compatibility | Suitable for small engines, carburetors, exhaust systems, oil pans, motorcycles, power tools, and lawn mowers |

Ever been in the middle of a lawn mower tune-up, only to realize the gasket you’ve got isn’t quite the right size or just doesn’t seal well? That frustration ends when you switch to this TNJPSEK gasket sheet kit.

I grabbed a set of these three sheets, and they immediately made my DIY repairs smoother.

The sheets are a generous 13.8 by 11.8 inches, giving plenty of room to cut out precisely what you need. The 0.8mm thickness feels sturdy but still easy to trim with scissors or a craft knife.

I used one to replace a carburetor gasket on a small engine, and it fit perfectly without any leaks.

The material is non-asbestos, which is a huge plus for safety and durability. It handled the heat from the exhaust and oil contact without warping or breaking down.

Plus, it tolerates up to 550°F—more than enough for most lawn equipment and small engines.

What I really appreciated was how well it stayed compressed even after multiple installations. No shifting or losing shape, which is critical in vibration-heavy environments like a mower engine.

Cutting custom shapes was straightforward, making it a versatile choice for various repair needs.

Overall, this gasket kit offers a practical, cost-effective solution. It simplifies the DIY process, helping you get back to work quickly without waiting for specialized parts.

It’s a reliable, long-lasting option that feels like a real upgrade over generic or worn-out gaskets.

TNJPSEK 6 Sheets Non-Asbestos Gasket Material Kit, 13.8″ x

- ✓ Easy to cut and shape

- ✓ Multiple thickness options

- ✓ High temperature endurance

- ✕ Slightly thicker sheets could be tougher to trim

- ✕ Not pre-cut for specific parts

| Material Composition | Non-asbestos composite |

| Maximum Temperature Endurance | 550°F (288°C) |

| Sheet Dimensions | 13.8 inches x 11.8 inches |

| Available Thicknesses | 0.8mm, 1.0mm, 1.2mm |

| Compatibility | Lawn mowers, carburetors, small engines, generators, power tools, automotive repairs |

| Environmental Resistance | Resistant to gasoline, diesel, and oil environments |

I was surprised to find how easy it was to customize this gasket material to fit my lawn mower’s carburetor. I initially thought I’d struggle cutting it precisely, but the sheets are soft enough to cut cleanly with just scissors.

It’s a real game changer for quick repairs.

The variety of thickness options—0.8mm, 1.0mm, and 1.2mm—meant I could pick just the right fit without guessing. I experimented with the 1.0mm sheet first, and it sealed perfectly without any leaks.

The fact that I could easily trace and shape it to match the old gasket saved me a lot of time.

The material feels sturdy and resilient. It handles heat well, even in small engines that get pretty hot, without warping or breaking down.

I was able to reinstall my carburetor and fire up the mower, and it kept a tight seal through multiple uses.

What I really appreciated is how versatile this kit is. I’ve used it on my motorcycle, my generator, and now my lawn mower.

It’s a reliable, all-around solution that’s worth having on hand for any small engine repair.

Overall, this gasket kit is a real time-saver. It’s affordable, flexible, and durable enough to handle the demands of everyday repairs.

If you’re tired of struggling with hard-to-cut or low-quality gasket material, this one’s a solid choice.

Strongthium Non-Asbestos Gasket Sheets 14-9/16″ x 11-27/64

- ✓ Large, versatile size

- ✓ Easy to cut and shape

- ✓ High resistance to oil and heat

- ✕ Slightly stiff for very intricate cuts

- ✕ May be overkill for small, quick fixes

| Material | High-quality asbestos-free composite with resistance to oil, high temperatures, high pressure, and penetration |

| Sheet Dimensions | 14-9/16 inches x 11-27/64 inches (370mm x 290mm) |

| Thickness Options | 0.5mm (1/64 inch) and 0.8mm (1/32 inch) |

| Number of Sheets | 2 sheets per set |

| Temperature Resistance | Suitable for high-temperature applications (specific temperature not specified, inferred high temp resistance) |

| Application Compatibility | Suitable for small engine repairs, automotive gaskets, lawn mowers, leaf blowers, trimmers, and other DIY or industrial projects |

As soon as I laid eyes on the Strongthium Non-Asbestos Gasket Sheets, I noticed how sizable they are — 14-9/16″ by 11-27/64″. That extra room really comes in handy when you’re trying to craft custom gaskets for your lawn mower or small engine repairs.

Unlike thinner, flimsy sheets I’ve used before, these feel sturdy yet flexible enough to cut with a simple knife or scissors.

The set includes two different thicknesses — 1/64 inch and 1/32 inch — which is a real plus. I used the thinner sheet for a quick lawn mower carburetor repair, and the thicker one felt more durable for tougher jobs.

The material’s high-quality, asbestos-free composition is reassuring, especially when working around fuel or oil.

What surprised me most was how resistant these sheets are to oil, heat, and pressure. Whether I was sealing a leaf blower or a small engine, they held up without any signs of wear or leaks.

The material is also environmentally friendly, which I appreciate. It’s easy to work with, and I could customize shapes for different projects without fuss.

Overall, these gasket sheets seem built for both the DIYer and the professional. The size and versatility give you a lot of options, and the quality feels premium for the price.

I’d definitely reach for these first when tackling small engine repairs or garden equipment fixes.

What Is a Gasket Material for Lawn Mower Carburetors and Why Does It Matter?

A gasket material for lawn mower carburetors is a sealing component made from various materials that prevents fuel and air leaks between the carburetor and the engine. It ensures a tight seal, which is essential for optimal engine performance and efficiency.

According to the Engine Builders Association, proper gasket selection is crucial for maintaining engine integrity and performance, particularly in small engines like those found in lawn mowers.

Key aspects of gasket materials include their resistance to fuel and oil, temperature stability, and mechanical durability. Common materials used for lawn mower carburetor gaskets include rubber, cork, and composite materials. Each has unique properties: rubber gaskets offer flexibility and good sealing, cork gaskets provide a lightweight and effective barrier, while composite materials might offer enhanced durability and resistance to environmental factors.

This choice of gasket material significantly impacts engine performance. A poor-quality or improperly fitted gasket can lead to air leaks, resulting in an incorrect air-fuel mixture that can cause engine misfires, reduced power, and increased fuel consumption. Statistics show that improper sealing can reduce engine efficiency by up to 20%, leading to higher operational costs and potential engine damage.

The benefits of using the best gasket material for lawn mower carburetors include improved engine performance, enhanced fuel efficiency, and a longer lifespan for the engine components. Quality gaskets help maintain the ideal operating conditions, which can prevent costly repairs and extend the intervals between maintenance.

Best practices for selecting gasket materials involve considering factors such as the specific engine type, operating temperature, and the chemical compatibility of the gasket material with the fuels used. It’s recommended to consult manufacturer guidelines and choose gaskets that meet or exceed OEM specifications for the best results.

What Are the Most Common Types of Gasket Materials for Lawn Mower Carburetors?

The most common types of gasket materials for lawn mower carburetors include:

- Paper Gaskets: Paper gaskets are widely used due to their affordability and ease of manufacturing.

- Rubber Gaskets: Rubber gaskets offer excellent flexibility and sealing properties, making them suitable for various applications.

- Cork Gaskets: Cork gaskets are often used for their compressibility and ability to form a tight seal, especially in irregular surfaces.

- Composite Gaskets: Composite gaskets are engineered materials that combine different substances to enhance durability and resistance to fuel and oil.

- Metal Gaskets: Metal gaskets provide high strength and temperature resistance, making them ideal for high-performance applications.

Paper gaskets are typically made from cellulose fibers and are designed to be absorbed by fluids, making them effective in various low-pressure applications. They are lightweight and easy to cut into shape but may not withstand extreme temperatures or chemicals over time.

Rubber gaskets are made from synthetic or natural rubber, providing excellent sealing capabilities and resistance to oil and gasoline. These gaskets can accommodate movement and vibration, which is essential in a lawn mower’s operating environment.

Cork gaskets are made from natural cork material, recognized for their ability to compress and fill gaps, ensuring a tight seal. They also resist oil and fuel degradation, although they may require replacement more frequently than other materials due to wear.

Composite gaskets combine various materials, such as rubber and fiber, to create a durable and versatile sealing solution. They can withstand a wide range of temperatures and chemical exposures, making them suitable for more demanding applications.

Metal gaskets are constructed from materials like steel or aluminum and are used in high-performance engines where durability and heat resistance are critical. They are less compressible than other gasket types but provide a reliable seal in extreme conditions.

How Does Paper Gasket Material Perform in Lawn Mower Carburetors?

When considering the best gasket material for lawn mower carburetors, paper gasket material is a popular choice due to its unique properties and performance characteristics.

- Durability: Paper gaskets are designed to withstand a variety of environmental conditions, including exposure to oil, fuel, and temperature fluctuations.

- Compressibility: This material can compress effectively under the pressure of the carburetor assembly, ensuring a tight seal that minimizes the risk of leaks.

- Chemical Resistance: While not as resistant as some synthetic materials, paper gaskets are formulated to resist common carburetor fluids, providing sufficient protection in most lawn mower applications.

- Cost-Effectiveness: Paper gasket material is generally more affordable than alternatives, making it an economical choice for maintenance and repairs.

- Ease of Installation: The lightweight nature of paper gaskets makes them easy to handle and install, which is beneficial for quick repairs in lawn mower servicing.

Durability: Paper gaskets are engineered to withstand various environmental stresses, including exposure to fuel and oils, which are common in lawn mower carburetors. They offer a reliable sealing solution that can last through many operating cycles if properly installed.

Compressibility: The compressibility of paper gaskets allows them to fill in small imperfections on mating surfaces, ensuring a secure seal. This property helps reduce the likelihood of air leaks, which can adversely affect engine performance.

Chemical Resistance: Although paper gaskets do not have the same level of chemical resistance as rubber or silicone materials, they are treated to handle exposure to fuels and lubricants. This characteristic makes them suitable for many lawn mower carburetor environments, although care should be taken to ensure compatibility.

Cost-Effectiveness: One of the major advantages of paper gaskets is their low cost, making them a practical option for budget-conscious consumers. This affordability allows for easier maintenance and frequent replacement, which is crucial for lawn mower upkeep.

Ease of Installation: The simplicity of working with paper gaskets, due to their lightweight and flexible nature, facilitates quick and efficient installation. This ease of use is particularly beneficial for DIY enthusiasts and mechanics who need to perform repairs swiftly.

What Are the Unique Properties of Rubber Gasket Material?

Lastly, the cost-effectiveness of rubber makes it an accessible option for consumers and manufacturers alike, ensuring that lawn mower maintenance remains affordable while still achieving reliable performance.

How Does Cork Gasket Material Compare for Lawn Mower Uses?

| Material Type | Durability | Temperature Resistance | Common Uses |

|---|---|---|---|

| Cork | Moderate lifespan; can degrade over time with exposure to oil and gasoline. | Good up to 200°F; not ideal for extreme temperatures. | Commonly used for carburetor gaskets and other low-pressure applications. Advantages: Good compressibility and sealing properties. Disadvantages: Can absorb fuel and degrade faster than rubber. |

| Rubber | High durability; resistant to wear and tear. | Excellent; can withstand temperatures from -40°F to 400°F. | Used in various engine gaskets, including carburetors and seals. |

| Paper | Shorter lifespan; can tear easily under pressure. | Limited; typically rated around 150°F. | Often used in temporary gaskets and less demanding applications. |

| Silicone | Very durable; resistant to chemicals and wear. | Excellent; can handle extreme temperatures from -75°F to 500°F. | Used for high-performance applications and where high heat is present. |

| Recommendation | For lawn mower carburetors, rubber is often the best gasket material due to its high durability and wide temperature range. | ||

When Should You Use Metal Gasket Material for Lawn Mower Carburetors?

The best gasket material for lawn mower carburetors depends on various factors including temperature, pressure, and fuel compatibility.

- High-Temperature Resistance: Metal gaskets are ideal for applications where high temperatures occur, as they can withstand the heat generated by the engine without degrading.

- Fuel Compatibility: Metal gaskets are resistant to fuel and oil, making them suitable for carburetors that are exposed to gasoline or other petroleum-based fluids, ensuring a tight seal without deterioration.

- Durability and Longevity: Metal gaskets provide excellent durability over time, reducing the need for frequent replacements compared to composite materials which may wear out faster under harsh conditions.

- Pressure Applications: In high-pressure situations, metal gaskets can maintain their structural integrity, making them a reliable choice for maintaining optimal performance in the carburetor.

- Customization and Thickness: Metal gaskets can be manufactured in various thicknesses and shapes, allowing for customization to fit specific carburetor designs and ensuring a perfect fit.

What Factors Play a Role in Choosing the Right Gasket Material?

Choosing the right gasket material for a lawn mower carburetor involves several critical factors:

- Temperature Resistance: It’s essential to select a gasket material that can withstand the operating temperatures of the engine without degrading.

- Chemical Compatibility: The gasket must be resistant to fuel and oil, as these substances can cause certain materials to break down or swell.

- Compression Set Resistance: A good gasket material should maintain its shape and sealing ability under compression to prevent leaks.

- Thickness and Flexibility: The gasket needs to be thick enough to fill any gaps but flexible enough to conform to the mating surfaces for an effective seal.

- Durability and Longevity: The selected material should be durable to withstand repetitive cycles of heating and cooling without failing.

- Ease of Installation: The gasket should be easy to handle and install, allowing for a secure fit without requiring excessive force.

Temperature Resistance: The gasket material must be able to endure the high temperatures generated by the engine without losing structural integrity. Materials like silicone or certain composites are preferred for their high-temperature resilience, ensuring the gasket maintains its sealing properties during operation.

Chemical Compatibility: Lawn mower carburetors are exposed to various fuels and lubricants that can chemically interact with the gasket material. Choosing materials such as Nitrile or Viton can help ensure that the gasket remains intact and effective, resisting fuel-related degradation.

Compression Set Resistance: Over time, gaskets can experience compression set, where they lose their ability to return to their original shape after being compressed. Materials like rubber compounds are often chosen for their superior compression set resistance, ensuring long-lasting seals that prevent leakage.

Thickness and Flexibility: A properly designed gasket should be thick enough to fill gaps between surfaces while remaining flexible to adapt to minor surface irregularities. This adaptability is crucial for maintaining a tight seal even in less-than-perfect mating surfaces.

Durability and Longevity: The ideal gasket material should withstand constant exposure to engine cycles, including heat and pressure fluctuations, without failing. Durable materials, such as reinforced composites, are often used for their long life and resistance to wear.

Ease of Installation: Selecting a gasket material that is easy to handle and install is vital for ensuring a secure fit without damage during installation. Lightweight and pliable materials can be a significant advantage, allowing for quick and accurate positioning during assembly.

How Important Is Temperature Resistance for Gasket Material?

Temperature resistance is crucial for gasket materials, especially in applications like lawn mower carburetors where they are exposed to fluctuating temperatures and harsh conditions.

- Rubber Gaskets: Rubber gaskets are often used due to their flexibility and ease of installation, but their temperature resistance can vary. Standard rubber may degrade at high temperatures, making it less suitable for carburetor applications where heat can lead to failure and leaks.

- Silicone Gaskets: Silicone gaskets offer excellent temperature resistance, typically ranging from -60°F to 500°F. This makes them ideal for lawn mower carburetors, as they can withstand the heat generated by the engine without losing their sealing properties.

- Fiber Gaskets: Fiber gaskets, made from compressed cellulose or aramid fibers, provide good thermal stability and are often used in automotive applications. They can handle moderate temperatures, but may not perform as well as silicone under extreme conditions.

- Metal Gaskets: Metal gaskets are highly durable and can resist high temperatures, making them suitable for use in environments that experience significant heat. However, they may require a more precise installation to ensure a proper seal, which can be a consideration in carburetor applications.

- PTFE Gaskets: PTFE (Teflon) gaskets are known for their exceptional chemical and temperature resistance, capable of performing in temperatures up to 500°F. This makes them a great choice for high-performance lawn mower carburetors, ensuring that the seal remains intact under varying thermal stresses.

Why Is Fuel Resistance Critical in Gasket Material Selection?

Fuel resistance is critical in gasket material selection because it ensures that the gasket can withstand exposure to fuel without degrading, which could lead to leaks and potential engine failure.

According to the American Society for Testing and Materials (ASTM), materials that come into contact with fuels must demonstrate resistance to swelling, softening, and cracking to maintain their integrity over time (ASTM D471). This is particularly important in applications like lawn mower carburetors, where gaskets are subjected to volatile organic compounds present in gasoline.

The underlying mechanism involves the chemical interactions between the gasket material and the fuel. Hydrocarbons in fuel can penetrate certain materials, causing them to swell or lose their tensile strength. For example, materials like rubber and certain polymers may become compromised when exposed to gasoline, leading to the eventual failure of the seal. This deterioration can create pathways for fuel leaks, resulting in reduced engine performance, increased emissions, and safety hazards, highlighting the necessity of selecting gaskets made from fuel-resistant materials like fluorocarbon rubber or specific types of silicone.

Furthermore, the temperature fluctuations in engine environments exacerbate these issues. High temperatures can accelerate the degradation of less resistant materials, while cold temperatures can cause them to become brittle. The combination of these factors underscores the importance of selecting gaskets that are not only fuel-resistant but also capable of maintaining performance under varying temperature conditions to ensure the longevity and reliability of lawn mower carburetors.

What Are the Pros and Cons of Different Gasket Materials?

| Material Type | Pros | Cons |

|---|---|---|

| Rubber | Flexible, provides a good seal, resistant to oil and chemicals. Recommended for lawn mower carburetors due to good sealing properties. | Can deteriorate under extreme heat, may not last as long as other materials. |

| Cork | Cost-effective, easy to install, good compressibility. Suitable for lower temperature applications but not recommended for high-performance lawn mower carburetors. | Less durable, can absorb moisture, may require replacement more often. |

| Paper | Inexpensive, lightweight, suitable for low-pressure applications. Not ideal for lawn mower carburetors due to poor fluid resistance. | Not resistant to fluids, can tear easily, not ideal for high-temperature environments. |

| Metal | High durability, excellent for high-temperature and high-pressure environments. Recommended for performance-oriented lawn mower carburetors. | Can be expensive, requires precise installation to avoid leakage. |

What Do Experts Recommend as the Best Gasket Material for Lawn Mower Carburetors?

Experts recommend several gasket materials for lawn mower carburetors, each with specific advantages based on their properties and applications.

- Paper Gaskets: Paper gaskets are commonly used due to their affordability and ease of fabrication. They are suitable for low-pressure applications and can effectively seal fuel and oil in carburetors, but they may not withstand extreme temperatures or prolonged exposure to chemicals.

- Cork Gaskets: Cork gaskets are known for their excellent compressibility and resistance to fuel and oil. They provide a reliable seal and can accommodate slight irregularities in the surfaces they join, making them ideal for lawn mower carburetors that experience vibration and thermal expansion.

- Rubber Gaskets: Rubber gaskets are highly versatile and offer superior sealing properties, especially in wet or oily environments. They are durable and can withstand a wide range of temperatures, making them a popular choice for carburetors that require a robust seal to prevent leaks.

- Fiberglass Gaskets: Fiberglass gaskets provide exceptional heat resistance and are often used in high-performance applications. They maintain their integrity under extreme conditions, making them suitable for carburetors that operate at high temperatures, though they can be more expensive than other materials.

- Silicone Gaskets: Silicone gaskets are known for their flexibility and ability to withstand a broad temperature range. They are resistant to oils and fuels, making them perfect for lawn mower carburetors that may encounter varying fuel types and environmental conditions.