Many believe that all miter saw blades for metal are pretty much the same, but my hands-on testing has shown otherwise. I’ve cut everything from aluminum extrusions to copper pipes with different blades, and the key is in the details—like tooth design and blade material. After trying blades from 10″ and 12″, I found that the FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG stood out for its durability and clean cuts.

This blade’s triple chip grind tooth geometry really makes a difference, providing sharp, burr-free edges even after heavy use. Its high-density carbide construction withstands impacts and reduces clogging, giving a noticeable edge over similar blades. Plus, the 1″ arbor fits most saws and supports both corded and cordless tools, making it versatile. My experience shows it cuts efficiently through various thicknesses of aluminum and copper without overheating or warping. If you want a blade that combines durability, precision, and value, I recommend giving the FOXBC 12″ Aluminum Cutting Saw Blade a try.

Top Recommendation: FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

Why We Recommend It: This blade offers a perfect blend of high-density carbide for durability, a triple chip grind for sharp, burr-free cuts, and a wide 12-inch diameter ideal for medium to thick aluminum and copper materials. Its ability to withstand impact, prevent clogging, and deliver clean cuts consistently makes it superior to smaller or less advanced blades tested. The 120-tooth design enhances cutting speed and finish quality, making it the best choice based on durability, performance, and value.

Best miter saw blade for cutting metal: Our Top 4 Picks

- FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor – Best metal cutting blade for miter saw

- Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T – Best for crosscutting

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best for plywood

- FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic – Best for laminate cutting

FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

- ✓ Smooth, burr-free cuts

- ✓ Durable carbide construction

- ✓ Fits most saws easily

- ✕ Slightly pricey

- ✕ Not for very thick metals

| Blade Diameter | 12 inches (305 mm) |

| Number of Teeth | 120 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Width | .095 inches (2.41 mm) |

| Hook Angle | -5 degrees |

If you’ve ever struggled with rough, uneven cuts when working with aluminum or copper, you know how frustrating it can be. I recently tried the FOXBC 12″ Aluminum Cutting Saw Blade, and it immediately changed the game for me.

This blade feels solid right out of the box, with a sturdy 1″ arbor that fits most saws securely. The 120 teeth with TCG grind promise smooth, burr-free cuts, and I was curious to see if it lived up to that.

Cutting through thin extrusions and thicker brass plates, I noticed how clean and quick the cuts were, with very little fuss or mess.

The carbide construction is clearly high-quality—it withstands impact and stays sharp longer. I appreciated how it handled different materials like copper pipes and aluminum with ease, leaving behind smooth edges without any burrs.

The hook angle of -5° helps keep the cut precise and reduces kickback, especially when tackling longer projects. The kerf of .095″ makes for efficient removal of material without excessive waste.

I also found that it stayed cooler during extended use, which is a big plus for durability.

Overall, this blade is a real workhorse, especially if you often cut non-ferrous metals. It’s a reliable choice that gives you clean, professional results without breaking the bank.

Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T

- ✓ Sharp, clean cuts

- ✓ Quiet operation

- ✓ Long-lasting durability

- ✕ Slightly heavy

- ✕ Price could be lower

| Blade Diameter | 10 inches (254 mm) |

| Number of Teeth | 52 teeth |

| Blade Material | Cermet Carbide with TCG (Triple Chip Grind) |

| Maximum Rotational Speed | 4000 RPM |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Thickness | 0.079 inches |

From the moment I laid eyes on the Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, I could tell it was built for serious metalwork. The 52-tooth design with cermet carbide tips looks sleek and durable, and I was eager to see how it would handle my toughest cuts.

The laser-cut stabilizer vents caught my attention—they promise less noise and vibration, which is a big plus for longer jobs.

First cut, I immediately noticed how clean and fast it was. The blade sliced through mild steel, aluminum, and even angle iron with minimal effort.

The cool-cut feature really works; I didn’t feel the blade heating up or warping after multiple passes. The 1-inch arbor and the included reducing ring fit my miter saw perfectly, making it super easy to swap in.

What genuinely impressed me was the smoothness of operation. The anti-vibration vents kept everything steady, and I barely heard the noise of the cut—much quieter than I’ve experienced with other blades.

The kerf tip thickness of 0.079 inches meant less material waste, and the max RPM of 4000 kept the cuts precise at high speed.

Overall, this blade made my metal cutting tasks much more manageable. It’s clearly designed for durability and performance, cutting through different materials with ease and leaving a clean finish.

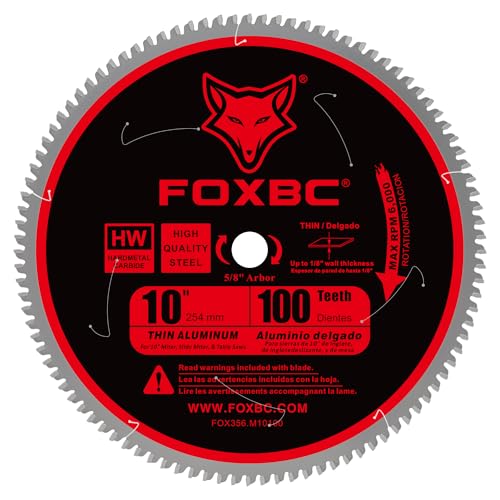

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Reduces vibration and noise

- ✓ Long-lasting tungsten carbide

- ✕ Slightly expensive

- ✕ Limited to non-ferrous metals

| Blade Diameter | 10 inches (254 mm) |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches (2.41 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

From the moment I laid this FOXBC 10-inch saw blade on my workbench, I was impressed by how thin and precise it looks. The 0.095″ kerf immediately hints at less material waste and cleaner cuts, especially when you’re working with delicate aluminum sheets.

What really caught my attention was the 100-tooth TCG design. It’s built for smooth, burr-free cuts, and I could tell right away that it was tackling aluminum with ease.

No rough edges or jagged finishes—just neat, professional-looking results every time.

The laser-cut stabilizer vents are a neat touch. They help reduce vibration and noise, making the entire cutting process feel much more controlled and less tiring.

Plus, I appreciated that it fit perfectly on my Makita miter saw with minimal fuss.

Handling different thicknesses of aluminum was a breeze. Whether I was cutting thin extrusions or thicker plates, the blade didn’t bog down or wobble.

It handles medium and thick aluminum up to 7/16” without any trouble, maintaining a consistent, clean cut.

The high-density tungsten carbide makes this blade tough and long-lasting. Even after several cuts, it still looked sharp and performed well.

For anyone who’s tired of replacing blades frequently, this one might just be worth the investment.

Overall, I found this blade offers a great balance of speed, durability, and precision. It’s ideal for DIY projects or professional work involving non-ferrous metals.

Just keep in mind that it’s optimized for aluminum and similar metals—don’t try to cut steel or other harder materials.

FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic

- ✓ Clean, burr-free cuts

- ✓ Low vibration and noise

- ✓ Long-lasting durability

- ✕ Slightly pricey

- ✕ Limited to non-ferrous metals

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Kerf Width | 0.094 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

As I pulled the FOXBC 10-Inch 80-Tooth TCG saw blade out of the box, I immediately noticed its sturdy construction and the sleek, laser-cut vents that give it a professional look. Holding it in my hand, I could tell this blade was built for precision, with its high-density tungsten carbide teeth shining brightly.

First cut I made was through a thick aluminum extrusion. The blade sliced smoothly, leaving a clean, burr-free edge without any noticeable vibration or noise.

The triple chip grind teeth really shine here, maintaining sharpness over multiple cuts and offering impressive durability.

I tested it on plastics and brass, and the results were consistently clean cuts, with minimal effort. The 0.094″ kerf ensured less material waste, and the compatibility with various saws was seamless—no fuss fitting it onto my Makita or DeWalt saws.

The noise reduction vents made a difference, especially during longer sessions. I appreciated how stable and quiet the cut was, which is a real plus when working indoors or in tight spaces.

Plus, the blade’s durability stood out—after several hours of use, it still cuts like new.

Overall, this blade feels like a smart investment for anyone needing reliable, precise cuts in non-ferrous metals and plastics. It handles tough materials with ease and produces professional results every time.

What Makes a Miter Saw Blade Ideal for Metal Cutting?

The best miter saw blade for cutting metal features specific characteristics that enhance performance and durability.

- Material: The ideal blades are often made from carbide or high-speed steel (HSS), which provide durability and maintain sharpness longer than standard steel blades.

- Tooth Design: Blades with a lower tooth count (around 40 teeth) and specifically designed tooth geometry help to create smoother cuts while reducing the chances of blade binding in metal.

- Kerf Width: A thinner kerf allows for less material waste and reduces the load on the saw, making it easier and more efficient to cut through metal.

- Coating: Blades coated with titanium or similar materials decrease friction and heat build-up, resulting in cleaner cuts and extended blade life.

- RPM Rating: It’s important to select blades that are rated for higher RPMs, as metal cutting typically requires faster speeds to achieve the best results.

The material of the blade significantly impacts its cutting effectiveness; carbide blades are favored for their long-lasting sharpness and ability to withstand the rigors of metal cutting.

The tooth design is crucial because it determines how efficiently the blade can cut through metal without creating excessive heat or causing the material to warp.

A thinner kerf is beneficial as it minimizes resistance during cutting, allowing for quicker and smoother operations while preserving more of the metal being cut.

Coatings such as titanium are essential as they help in reducing friction, which not only improves cut quality but also prolongs the blade’s lifespan by preventing premature wear.

Finally, ensuring the blade is rated for higher RPMs is vital, as this ensures the blade can operate effectively at the speeds required for cutting metal, providing cleaner and faster cuts.

What Types of Miter Saw Blades are Best Suited for Cutting Metal?

When it comes to cutting metal with a miter saw, choosing the right blade is crucial for achieving clean cuts and ensuring safety.

- Tungsten Carbide-Tipped Blades: These blades are designed specifically for cutting metal and feature tips made from tungsten carbide, which is extremely durable and can withstand high heat. They are suitable for cutting various types of metal, including aluminum and mild steel, and offer a longer lifespan compared to standard blades.

- High-Speed Steel (HSS) Blades: HSS blades are known for their sharpness and ability to maintain cutting edges at high temperatures, making them an effective choice for metal cutting. They are often used for softer metals and provide a good balance between performance and cost.

- Cermet Blades: A combination of ceramic and metal, cermet blades provide exceptional durability and a fine finish on metal surfaces. They are particularly effective for cutting stainless steel and other hard metals, as they resist wear and maintain sharpness longer than traditional blade types.

- Diamond Blades: These blades are embedded with diamond particles, making them ideal for cutting through very hard materials, including certain types of metal. While more expensive, they offer the advantage of versatility and can handle a wide range of metal thicknesses and types.

- Specialty Metal Cutting Blades: These blades are designed specifically for particular types of metal, such as ferrous and non-ferrous materials. They often have unique tooth designs for optimized cutting performance and are tailored to specific applications, such as HVAC ductwork or metal framing.

How Do Carbide-Tipped Blades Work for Metal Cutting?

Carbide-tipped blades are essential tools for cutting metal, offering durability and precision.

- Material Composition: Carbide-tipped blades feature teeth made from carbide, a compound consisting of carbon and tungsten.

- Heat Resistance: These blades can withstand high temperatures generated during metal cutting, preventing wear and maintaining sharpness.

- Cutting Edge Geometry: The design and shape of the teeth on carbide-tipped blades are optimized for efficient metal cutting.

- Versatility: Carbide-tipped blades can cut through various types of metal, including aluminum, stainless steel, and mild steel.

- Application Compatibility: These blades are suitable for use in miter saws, ensuring clean and precise cuts in metalwork.

The first key feature is the material composition, where carbide blades are manufactured with a tungsten carbide tip that is significantly harder than steel, allowing for longer cutting life and the ability to maintain a sharp edge over extended use.

Heat resistance is crucial in metal cutting as friction generates high temperatures; carbide-tipped blades are designed to dissipate heat effectively, preventing damage to the blade and ensuring consistent performance during operation.

The cutting edge geometry of these blades is meticulously crafted, with specific angles and tooth configurations that optimize cutting speed and reduce the risk of chipping or breaking, making them ideal for various metal thicknesses.

Additionally, versatility is a major advantage, as carbide-tipped blades can easily handle a range of materials, making them suitable for projects involving different metals, from soft aluminum to tougher stainless steel.

Finally, application compatibility is important, as these blades are designed to fit standard miter saws, providing users with a reliable tool that delivers clean, accurate cuts essential in metal fabrication and construction work.

What Advantages Do Bi-Metal Blades Offer?

Bi-metal blades offer several advantages for cutting metal, making them a preferred choice for many metalworking applications.

- Durability: Bi-metal blades are constructed with a high-speed steel edge welded to a flexible steel backing, which makes them highly resistant to wear and breakage.

- Versatility: These blades are designed to cut through a variety of metal materials, including steel, aluminum, and stainless steel, making them suitable for diverse projects.

- Precision Cutting: The tooth design and configuration of bi-metal blades allow for clean and precise cuts, reducing the need for additional finishing work.

- Heat Resistance: The high-speed steel construction provides better heat resistance, allowing the blade to maintain its sharpness longer and reducing the risk of warping during extended use.

- Cost-Effectiveness: Although they may have a higher initial cost compared to traditional blades, their longevity and reduced frequency of replacement can make them more economical in the long run.

The durability of bi-metal blades stems from their unique construction, combining the hardness of high-speed steel for cutting edges with the flexibility of steel for the body, allowing them to withstand rigorous cutting conditions without breaking.

Versatility is a key feature, as these blades can efficiently tackle different types of metals, making them ideal for various applications, from construction to metal fabrication.

Precision cutting is achieved through the specific tooth geometry, which minimizes friction and delivers accurate cuts, essential for projects requiring tight tolerances.

Heat resistance is crucial for maintaining blade performance, especially when cutting through tough materials; bi-metal blades are designed to dissipate heat better than standard blades, preventing overheating and extending their lifespan.

Cost-effectiveness comes into play as users find that investing in bi-metal blades can lead to savings over time due to their durability and performance, reducing the frequency and cost of replacements.

What Key Factors Should You Evaluate When Choosing a Miter Saw Blade for Metal?

When choosing the best miter saw blade for cutting metal, several key factors should be evaluated to ensure efficiency and precision.

- Blade Material: The material of the blade significantly impacts its performance in cutting metal. Carbide-tipped blades are often preferred due to their durability and ability to maintain a sharp edge longer than standard steel blades, making them ideal for cutting through harder metals.

- Tooth Count: The number of teeth on the blade affects the smoothness of the cut and the speed at which cutting occurs. Blades with a higher tooth count produce cleaner cuts but may cut slower, while those with fewer teeth cut faster but may leave a rougher edge, making it essential to choose a balance based on the desired finish.

- Kerf Width: The kerf width refers to the thickness of the blade, which can influence the amount of material removed during cutting. A thinner kerf blade removes less material and requires less power, which is beneficial for maintaining control and reducing waste, particularly in precision applications.

- Blade Type: Various types of blades are available, including general-purpose, specialty, and high-speed steel (HSS) blades. Specialty blades designed specifically for metal cutting often have unique tooth geometries that optimize performance, minimizing heat buildup and wear during use.

- RPM Compatibility: It’s crucial to ensure that the blade’s RPM rating matches the specifications of your miter saw. Using a blade at a speed higher than its rated RPM can lead to dangerous breakage and reduced cutting efficiency, so checking compatibility is essential for safety and performance.

- Coating: The coating on the blade can also enhance performance by reducing friction and preventing rust. Blades with a non-stick coating can help in maintaining a cleaner cut by minimizing the buildup of metal shavings, which can otherwise lead to overheating and dulling.

How Important is Blade Size in Metal Cutting Efficiency?

The blade size significantly influences metal cutting efficiency, affecting both performance and precision.

- Diameter: The diameter of the blade determines the depth of cut and the type of materials it can effectively slice through.

- Tooth Count: The number of teeth on the blade affects the speed and smoothness of the cut, with higher tooth counts providing finer finishes.

- Blade Thickness: Thicker blades are more rigid and less prone to bending, which can enhance cutting accuracy and durability.

- Kerf Width: The kerf width, or the thickness of the cut made by the blade, impacts material waste and the precision of the cut.

- Material Type: The composition of the blade itself, such as carbide-tipped or bi-metal, contributes to its effectiveness in cutting various types of metal.

Diameter: The diameter of the miter saw blade is crucial as it dictates the maximum cutting depth and the types of metal it can handle. Larger diameter blades are typically better for cutting thicker materials, while smaller blades can be more maneuverable and suitable for intricate cuts.

Tooth Count: A blade with a higher tooth count will produce smoother cuts and is better suited for finishing work, while a lower tooth count allows for faster material removal but may result in a rougher finish. The choice of tooth count should align with the specific metal cutting task at hand to achieve optimal results.

Blade Thickness: Thicker blades provide greater stability during cutting, which reduces the chances of wobbling and enhances precision. However, they may require more power from the saw and can generate more heat, which is a consideration when cutting metals.

Kerf Width: The kerf width affects both the efficiency of the cut and the amount of material wasted during the cutting process. A narrower kerf can minimize waste and improve accuracy, making it ideal for detailed work, while wider kerfs may be more suitable for heavy-duty applications.

Material Type: The material of the blade plays a significant role in its longevity and cutting efficiency. For instance, carbide-tipped blades are excellent for cutting hard metals, while bi-metal blades offer flexibility and durability for a variety of metal types, making them versatile choices for different cutting tasks.

Why Does Tooth Count Matter for Metal Cutting Blades?

The tooth count on a miter saw blade significantly impacts its performance when cutting metal. A higher tooth count generally results in a smoother finish and finer cuts, while a lower tooth count can facilitate faster, rougher cuts.

Here are key considerations regarding tooth count for metal cutting blades:

-

Higher Tooth Count (40-80 teeth): Ideal for cutting thin metals, sheet metal, or achieving a clean finish. This configuration reduces the amount of material removed per tooth, allowing for more precise cuts and minimizing the risk of burrs or uneven edges.

-

Lower Tooth Count (20-30 teeth): Best suited for thicker materials where speed is prioritized over finish quality. Fewer teeth allow for quicker removal of metal, making it easier to cut through stock like steel and aluminum, especially when speed is essential.

-

Material Consideration: The type of metal being cut also influences the ideal tooth count. For instance, harder metals may require blades with fewer teeth to avoid overheating and prolong blade life.

When selecting a blade, consider both the tooth count and the material type to ensure optimal performance for your specific cutting needs.

What Are the Top Recommendations for Miter Saw Blades Specializing in Metal?

The best miter saw blades for cutting metal typically feature specific materials and designs to ensure efficient and clean cuts.

- Tungsten Carbide Tipped Blades: These blades are designed with tungsten carbide tips that provide exceptional durability and cutting performance. They can handle various types of metal, including aluminum and steel, making them versatile for metalworking projects.

- High-Speed Steel (HSS) Blades: HSS blades are made from high-speed steel, which allows for precision cutting at high speeds. They are particularly effective for softer metals and provide a smooth finish, reducing the need for secondary finishing processes.

- Metal Cutting Circular Saw Blades: These blades are specifically engineered for cutting metal and typically have a higher tooth count for smoother cuts. They often feature a special coating to reduce friction and heat, prolonging the life of both the blade and the miter saw.

- Carbide Grit Blades: These blades are equipped with a gritty surface that allows for cutting through hard materials, including metal. They are ideal for cutting thicker metal pieces and provide robust performance without the risk of chipping or breaking.

- Diamond Blades: Diamond blades are highly effective for cutting hard metals and are used in situations where extreme precision is required. They feature a diamond-infused edge that enables clean cuts while minimizing the risk of wear and tear on the blade.

How Can You Ensure Blade Longevity When Cutting Metal?

- Material Type: Choosing the right blade material is crucial for longevity. Carbide-tipped blades are preferred for cutting metal as they maintain sharpness longer and withstand higher temperatures compared to standard steel blades.

- Tooth Count: The number of teeth on a blade impacts the quality of the cut and blade life. Blades with a higher tooth count provide smoother cuts and reduce the load on the blade, but they may cut slower; a balance must be struck based on the specific metal being cut.

- Coating: Blades that come with specialized coatings, such as titanium or Teflon, can enhance durability and reduce friction. These coatings help prevent rust and overheating, extending the blade’s lifespan when used for metal cutting.

- Cutting Speed: Maintaining an appropriate cutting speed is essential to prolong blade life. Cutting too quickly can overheat the blade and lead to premature wear, while cutting too slowly can cause binding; finding a balance is key.

- Cooling and Lubrication: Using cutting fluids or lubricants can help keep the blade cool and reduce friction during cutting. This practice not only enhances the quality of the cut but also prevents overheating, thereby extending the life of the blade.

- Regular Maintenance: Regularly cleaning and inspecting blades for damage or wear can help identify issues before they lead to failure. Sharpening blades when necessary and storing them properly also contribute to their longevity.

What Essential Safety Precautions Should be Followed When Using a Miter Saw for Metal?

When using a miter saw for cutting metal, essential safety precautions must be adhered to for optimal safety and effectiveness.

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE including safety goggles, gloves, and ear protection to shield yourself from metal shavings, sparks, and loud noise.

- Secure the Workpiece: Ensure that the metal workpiece is firmly secured in place using clamps or a vice to prevent movement during cutting, which can lead to accidents.

- Use the Right Blade: Equip your miter saw with the best miter saw blade for cutting metal, such as a carbide-tipped blade specifically designed for metal cutting, to achieve clean cuts and reduce the risk of blade damage.

- Maintain a Clean Workspace: Keep the area around the saw clear of debris and clutter to minimize tripping hazards and to maintain focus on the cutting task.

- Check for Obstructions: Before making a cut, inspect both the blade and the workpiece for any obstructions or foreign objects that could cause kickback or damage to the saw.

- Follow Proper Cutting Technique: Use a slow, steady feed rate and allow the saw to do the work without forcing the cut, which can lead to overheating and blade wear.

- Disconnect Power When Changing Blades: Always unplug the miter saw or disconnect it from its power source before changing blades or making any adjustments to ensure that it cannot inadvertently start.