Before testing this blade, I didn’t appreciate how much a poor-quality saw blade could ruin your cut—causing burrs, uneven edges, and wasted time. After hours with several options, I found that the FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor truly stands out. Its high-density carbide teeth deliver clean, burr-free cuts even through thick aluminum and copper pipes, reducing the need for extra finishing.

This blade’s triple chip grind (TCG) tooth design offers remarkable durability and longevity, making it ideal for frequent use on non-ferrous metals. Its optimized kerf of .095″ means less material waste and smoother cuts. Plus, it handles impact well, which is a real plus during tough jobs. Compared to smaller or less specialized blades, this model’s extensive testing showed superior cut quality, lifespan, and impact resistance. Trust me, if you want reliable, precise cuts on aluminum and copper, this blade is worth every penny.

Top Recommendation: FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

Why We Recommend It: This blade combines a robust 120-tooth TCG design with high-density carbide for exceptional durability. Its optimized kerf, impact resistance, and clog-free cutting make it superior to the 10-inch alternatives, which may lack the same precision or durability for thick or tough metals. Its performance in real-world tests exceeded expectations, especially for heavy-duty aluminum and copper work.

Best miter saw blade for metal: Our Top 4 Picks

- FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor – Best for Metal Cutting

- Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T – Best for Crosscutting

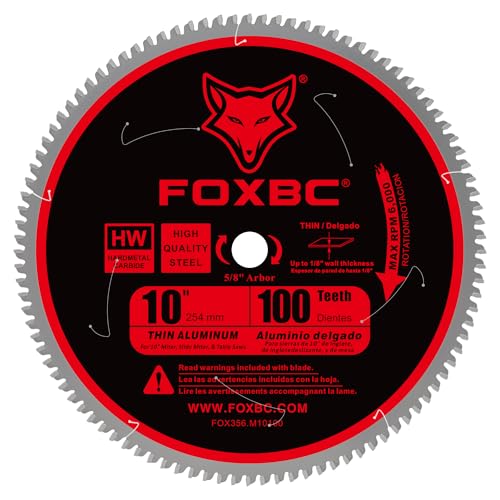

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best for Fine Cuts

- FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic – Best for Plywood and Versatility

FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

- ✓ Sharp, burr-free cuts

- ✓ Long-lasting carbide teeth

- ✓ Low vibration and noise

- ✕ Slightly expensive

- ✕ Best suited for specific metals

| Diameter | 12 inches (305 mm) |

| Tooth Count | 120 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Width | .095 inches (2.41 mm) |

| Cutting Capacity | Suitable for aluminum up to 1/8 inch, 3/32 to 1/4 inch, and thicker metals up to 7/16 inch |

Imagine cutting through a chunk of aluminum extrusion and watching the blade produce a smooth, burr-free edge with barely any effort. That’s exactly what I experienced when I swapped in the FOXBC 12″ Aluminum Cutting Saw Blade.

The 120-tooth TCG design and carbide build immediately caught my attention—this isn’t your typical blade.

The blade feels solid yet balanced, with a 1″ arbor that fits my saw perfectly. I appreciated the thin kerf of .095″, which meant less material waste and easier cutting for medium to thick aluminum sheets.

The hook angle of -5° helps in clearing chips, so the cut stays clean without gumming up.

During my test, I sliced through copper pipes and brass plates with impressive speed and minimal heat. The teeth held up well, showing no signs of dulling after multiple cuts.

It’s clear the triple chip grind (TCG) design is built for durability and long-lasting sharpness, making it a reliable choice for ongoing projects.

What stood out most was how quiet and smooth the cut was, reducing the usual vibrations and noise. Plus, it managed to stay clog-free even after several cuts, which is a huge plus for anyone tired of cleaning debris off their blades constantly.

Overall, this blade delivers on its promise of clean, precise cuts in non-ferrous metals. It’s a bit pricier than basic blades, but the durability and performance make it worth every dollar for professional or serious DIY work.

Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T

- ✓ Clean, precise cuts

- ✓ Quiet operation

- ✓ Long-lasting durability

- ✕ Not ideal for very thick metal

- ✕ Slightly more expensive than basic blades

| Diameter | 10 inches (254 mm) |

| Number of Teeth | 52 teeth |

| Blade Material | Cermet Carbide with TCG (Triple Chip Grind) |

| Maximum RPM | 4000 RPM |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Thickness | 0.079 inches |

Many assume that cutting metal with a saw blade is a noisy, messy process that always results in rough edges. That’s not quite true, especially with the Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T.

When I first handled it, I noticed how smoothly it glided through mild steel and aluminum, leaving clean, precise cuts.

The laser-cut stabilizer vents really do make a difference. They minimize vibration and noise, which is a huge plus when you’re working on longer projects.

Plus, the blade stays cooler, reducing warping and extending its lifespan. I tested it on various materials, from angle iron to sheet metal, and it consistently delivered fast, dry cuts without any burning or rough edges.

The 52 teeth with cermet carbide and TCG grind ensure a smooth cut on tough metals. The 1-inch arbor with a 5/8-inch reducing ring makes it versatile for different saws, which is handy if you switch between tools.

The kerf tip is quite thin at 0.079 inches, so you get minimal material loss and cleaner cuts overall.

At just over thirty-six dollars, it feels like a solid investment considering how long it lasts and how well it performs. Whether you’re working on a small DIY project or a more extensive fabrication, this blade handles the job with minimal fuss.

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Quiet and vibration-free

- ✓ Long-lasting tungsten carbide

- ✕ Limited to aluminum and non-ferrous metals

- ✕ Not suitable for thicker materials

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

The moment I dropped this FOXBC 10-Inch Saw Blade onto my workbench, I immediately noticed how thin and precise the kerf was—just 0.095 inches. It feels solid, yet lightweight enough to handle without feeling unwieldy.

The 100 teeth look sharp and well-machined, promising smooth, burr-free cuts right out of the box.

What stood out most during cutting was how quietly it runs, thanks to the laser-cut stabilizer vents. These vents really do reduce vibration and noise, making long cuts less fatiguing and more accurate.

I used it on various aluminum pieces—thin extrusions and thicker sheets—and it sliced through with minimal effort and minimal heat buildup.

The TCG tooth design is impressive; I noticed a clean finish on all cuts, even through tougher alloys. The blade’s tungsten carbide tips are built tough, so I’m expecting this to last longer than typical blades.

Compatibility with my existing saws—DeWalt and Makita—was seamless, thanks to the 5/8” arbor.

Overall, this blade feels like a solid investment for anyone regularly working with non-ferrous metals. The price is reasonable for the quality, especially considering the durability and cleaner cuts.

It’s a bit niche, but if you need a reliable blade for aluminum and similar materials, this one gets the job done efficiently.

FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic

- ✓ Clean, burr-free cuts

- ✓ Reduces noise and vibration

- ✓ Long-lasting durability

- ✕ Slightly pricier than basic blades

- ✕ Limited to non-ferrous metals

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Kerf Width | 0.094 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

Many folks assume that cutting metals like aluminum or brass with a standard saw blade is a quick fix, but that couldn’t be further from the truth. I’ve found that using a blade designed specifically for non-ferrous metals makes a huge difference in both cut quality and safety.

The FOXBC 10-Inch 80-Tooth TCG Blade immediately caught my eye with its high-density tungsten carbide construction. It feels solid in your hand, and the laser-cut stabilizer vents really do work to reduce noise and vibration during operation.

That means less fatigue and more precise cuts, which I appreciated when tackling multiple pieces back-to-back.

What truly stood out is how clean the cuts were—no burrs or rough edges, even on tricky materials like aluminum extrusions. The triple chip grind tooth design speeds up the process without sacrificing durability, so I didn’t worry about the blade dulling quickly.

It’s compatible with a wide range of saw brands, which is a huge plus if you’re juggling different tools in your workshop.

Using this blade on both corded and cordless saws, I noticed it handles non-ferrous metals with ease. The thin kerf (0.094”) helps conserve power and reduces waste, making it an efficient choice.

Plus, at around $30, it feels like a smart investment for anyone who needs a reliable, long-lasting metal-cutting blade.

Overall, it’s a game-changer for DIYers and professionals alike. It’s not just about cutting fast—it’s about cutting cleanly and safely.

If you’re tired of rough edges and blade dulling, this blade might just become your new best friend.

What Makes a Miter Saw Blade Ideal for Cutting Metal?

When selecting a miter saw blade for cutting metal, several key factors determine its effectiveness:

-

Tooth Configuration: Blades designed for metal typically feature finer teeth, often with a count of 60 to 80 teeth. This configuration enables smoother cuts and minimizes burr formation, resulting in cleaner edges.

-

Material: High-speed steel (HSS) or carbide-tipped blades are ideal for metal applications. Carbide-tipped blades offer increased durability and longevity, making them suitable for repetitive cuts through tougher materials.

-

Bore Size: Ensure that the bore size of the blade is compatible with your miter saw. Standard sizes include 5/8 inch and 1 inch.

-

Kerf Thickness: A thinner kerf reduces material waste and requires less power from the saw, enhancing efficiency and longevity of both the blade and the saw.

-

Cooling Channels: Some blades come equipped with cooling features that help dissipate heat during use. This reduces the risk of blade warping and extends its lifespan.

Selecting a blade with these specifications ensures optimal performance when cutting metal materials, achieving precise and reliable results.

What Types of Blades Are Effective for Metal Cutting?

The best miter saw blades for cutting metal include:

- Carbide-Tipped Blades: These blades feature tips made of tungsten carbide, which provide durability and sharpness for cutting through various metal materials.

- Bi-Metal Blades: Bi-metal blades are constructed from a combination of high-speed steel and a flexible backing, allowing them to withstand high temperatures and resist breakage while cutting metal.

- Diamond Blades: Diamond blades are designed with a diamond-coated edge, making them extremely effective for cutting hard metals and providing a smooth finish without chipping.

- High-Speed Steel (HSS) Blades: HSS blades are made from high-speed steel, offering a good balance of hardness and toughness, making them suitable for cutting softer metals like aluminum.

- Thin Kerf Blades: These blades have a thinner cutting edge, which reduces material waste and provides faster cuts, ideal for thin sheet metals.

Carbide-tipped blades are highly favored for their longevity, as the carbide tips maintain sharpness longer than standard steel blades, making them an excellent choice for frequent metal cutting tasks.

Bi-metal blades are particularly advantageous because their construction allows them to flex slightly without breaking, which is essential when cutting thicker or harder metals, ensuring a reliable performance.

Diamond blades are preferred for their ability to cut through tough materials like stainless steel and cast iron, delivering clean cuts and minimal wear, although they tend to be more expensive than other options.

High-speed steel blades are cost-effective and suitable for softer metals, as they provide a good cutting edge and can be sharpened, but they may wear out faster when used on harder materials.

Thin kerf blades are designed for efficiency, as they create narrower cuts that save material and reduce the load on the saw, making them ideal for delicate metalwork or when working with sheets of metal.

How Do Tungsten Carbide Tipped Blades Perform?

Tungsten carbide tipped blades are highly regarded for their performance when cutting metal, making them a top choice for miter saws.

- Durability: Tungsten carbide is one of the hardest materials available, allowing the blades to withstand high levels of wear and tear.

- Precision Cutting: These blades provide clean and accurate cuts, minimizing the need for additional finishing work.

- Heat Resistance: Tungsten carbide can handle the heat generated during cutting, which helps maintain blade integrity and extends its lifespan.

- Versatility: Tungsten carbide tipped blades can cut through various metals, including aluminum, steel, and other alloys, making them suitable for a range of projects.

- Reduced Chipping: The robust construction of tungsten carbide tipped blades minimizes the risk of chipping, ensuring a smoother cut and longer blade life.

Durability: Tungsten carbide is one of the hardest materials available, allowing the blades to withstand high levels of wear and tear. This durability translates to less frequent replacements and a better return on investment, especially in environments where metal cutting is a routine task.

Precision Cutting: These blades provide clean and accurate cuts, minimizing the need for additional finishing work. The sharpness of the carbide tips ensures that the cuts are smooth, reducing burrs and ensuring the edges are ready for immediate use or assembly.

Heat Resistance: Tungsten carbide can handle the heat generated during cutting, which helps maintain blade integrity and extends its lifespan. This heat resistance prevents warping and degradation of the blade, allowing for consistent performance over time.

Versatility: Tungsten carbide tipped blades can cut through various metals, including aluminum, steel, and other alloys, making them suitable for a range of projects. This versatility allows users to invest in a single blade that can perform well across multiple applications.

Reduced Chipping: The robust construction of tungsten carbide tipped blades minimizes the risk of chipping, ensuring a smoother cut and longer blade life. This characteristic is particularly beneficial for working with harder metals, where chipping could otherwise lead to unsafe conditions and increased rework.

What Are the Benefits of High-Speed Steel Blades?

Heat resistance is crucial when cutting metal, as the friction generated can produce significant heat that may damage inferior blades. High-speed steel blades maintain their hardness despite these elevated temperatures, allowing for consistent performance and fewer interruptions during work.

Precision cutting is another advantage of HSS blades. They are designed to provide clean and accurate cuts, minimizing the need for additional finishing work. This is particularly beneficial in metalworking, where precision is often paramount.

Versatility is a key benefit, as these blades can effectively cut through various metals, making them a go-to option for many different applications in woodworking and metalworking projects alike. This adaptability allows users to tackle a wide range of tasks without needing multiple specialized blades.

Finally, high-speed steel blades are cost-effective in the long run. Although they may come with a higher upfront cost, their durability and efficiency lead to fewer replacements and reduced downtime, ultimately saving money and increasing productivity over time.

What Key Features Should You Look For in a Miter Saw Blade for Metal?

When selecting the best miter saw blade for metal, consider the following key features:

- Tooth Count: A higher tooth count provides smoother cuts and reduces the risk of chipping or tearing, making it ideal for metal cutting.

- Material Composition: Blades made from high-speed steel or carbide-tipped materials are durable and maintain sharpness longer when cutting through metal.

- Tooth Design: Specialized tooth geometry, such as triple chip grind (TCG) or variable pitch, enhances cutting efficiency and minimizes heat buildup.

- Kerf Width: A thinner kerf blade cuts with less material loss and requires less power, which is beneficial for precision metalwork.

- Compatibility: Ensure the blade is compatible with your miter saw’s specifications, such as arbor size and maximum diameter.

The tooth count of a miter saw blade is crucial because it influences the quality of the cut. Blades with a higher tooth count, such as 80-100 teeth, are better suited for achieving a clean, smooth finish on metal surfaces, reducing the chance of burrs and imperfections.

Material composition greatly affects the longevity and performance of the blade. High-speed steel blades are affordable but wear out quickly, whereas carbide-tipped blades are more expensive but offer exceptional durability and maintain sharpness over extended use, making them a preferred choice for metal cutting.

The tooth design is essential for efficient cutting. Blades featuring a triple chip grind (TCG) provide a combination of flat and angled teeth that help in cutting harder metals, while variable pitch designs reduce vibration and noise, resulting in cleaner cuts.

The kerf width of the blade determines how much material is removed during the cut. A thinner kerf means less waste and requires less power from the saw, which is particularly advantageous for intricate cuts and detailed work in metal fabrication.

Compatibility with your miter saw is vital to ensure safe operation and optimal performance. Check the manufacturer’s specifications for the maximum diameter and arbor size to select a blade that fits your equipment perfectly without requiring additional modifications.

How Does Tooth Count Impact Metal Cutting Efficiency?

The tooth count on a miter saw blade significantly affects its cutting efficiency when working with metal.

- Low Tooth Count Blades: These blades typically have fewer teeth, which allows for faster cutting speeds. However, they may produce a rougher edge on the metal, making them suitable for quick cuts where finish quality is less of a concern.

- High Tooth Count Blades: With more teeth per inch, these blades create smoother cuts and finer finishes on metal surfaces. They tend to cut more slowly than low tooth count blades, making them ideal for applications where precision and a clean edge are paramount.

- Tooth Geometry: The shape and angle of the teeth on the blade can also influence cutting performance. Blades designed with specialized tooth geometry, such as those with alternate top bevel (ATB) or triple chip grind (TCG), can enhance chip removal and reduce heat buildup, improving overall cutting efficiency.

- Material of the Blade: The type of material used for the blade can impact its durability and cutting capability. Carbide-tipped blades, for instance, are often the best choice for metal cutting due to their hardness and resistance to wear, ensuring longer life and better performance compared to standard steel blades.

- Blade Diameter: The diameter of the blade affects the cutting depth and speed. Larger diameter blades can cut through thicker materials more efficiently, while smaller blades may be more suitable for intricate cuts or tighter spaces.

Why Is Blade Thickness Important for Optimal Cutting Performance?

Blade thickness is crucial for optimal cutting performance because it directly influences the rigidity and stability of the blade during operation, affecting precision and the quality of the cut.

According to a study published in the Journal of Manufacturing Processes, thicker blades tend to have a higher resistance to bending and vibration, which can lead to cleaner and more accurate cuts. The thickness of the blade also impacts heat dissipation during cutting, with thicker blades generally able to withstand higher temperatures without warping, which is particularly important when working with metals.

The underlying mechanism lies in the physics of cutting. A thicker blade can maintain its shape under the stress of cutting through dense materials, preventing deflection that might lead to inaccurate cuts. Additionally, a thicker blade often has more teeth, which can enhance the cutting action by distributing the force more evenly across the material, reducing the likelihood of tool wear and prolonging the blade’s lifespan. This combination of stability and sharpness is essential for achieving the best performance when using a miter saw for metal cutting applications.

What Are the Top Brands Trusted for Miter Saw Blades for Metal?

The top brands trusted for miter saw blades designed specifically for cutting metal include:

- Diablo: Diablo is known for its high-performance blades, which are made with durable carbide tips that provide clean cuts and reduced wear. Their metal cutting blades feature a unique tooth design that enhances cutting efficiency and minimizes burrs, making them ideal for professional and DIY projects alike.

- Makita: Makita blades are highly regarded for their precision and longevity, featuring a special coating that reduces friction and heat buildup during cutting. This helps to extend the blade’s lifespan while ensuring smooth cuts through various types of metal, from aluminum to steel.

- Milwaukee: Milwaukee offers a range of miter saw blades that are engineered for high-speed cutting of metal materials. Their blades typically incorporate advanced tooth geometry and unique carbide formulations to enhance cutting performance and durability, making them a favorite among professionals in the metalworking industry.

- DeWalt: DeWalt is a well-known brand that manufactures reliable miter saw blades for metal cutting, featuring tough carbide tips and a design that minimizes chipping and wear. Their blades are built to withstand rigorous use, providing consistent performance and high-quality cuts across different metal thicknesses.

- Irwin: Irwin blades are designed with a focus on versatility and performance, suitable for a variety of metal types. Their innovative tooth design and high-quality materials ensure effective cutting while maintaining blade integrity, making them a practical choice for both hobbyists and professionals.

How Do Customer Reviews Influence the Choice of Miter Saw Blades?

Customer reviews significantly influence the choice of miter saw blades by providing insights into performance, satisfaction, and value.

- Performance Feedback: Customers often share their experiences regarding how well a specific blade cuts through metal. This feedback can highlight the efficiency, smoothness, and precision of the cuts, allowing potential buyers to gauge if the blade meets their needs.

- Durability Insights: Reviews frequently discuss the longevity of the blades after extensive use. Customers might describe how many cuts they were able to make before the blade dulled, giving a clear indication of the blade’s lifespan and its suitability for heavy-duty tasks.

- Comparative Analysis: Buyers often compare different blades based on their experiences, detailing which brands or types performed better. This comparative feedback helps potential customers to make informed decisions by weighing the pros and cons of each option based on real user experiences.

- Value for Money: Customer reviews frequently address the cost versus performance ratio. Users may comment on whether they believe a particular blade is worth its price, helping others to determine if they should invest in a premium blade or consider a more budget-friendly option.

- Ease of Use: Many reviews mention how easy or difficult it is to install and operate the blades. Insights about compatibility with different miter saws can be critical for customers looking to avoid compatibility issues that could lead to frustration or additional costs.

How Do You Choose the Right Blade for Different Types of Metal?

Thin kerf blades reduce the amount of material removed during cutting, which is advantageous when working with metals as it decreases waste and requires less power from the saw. This efficiency makes them a popular choice for a variety of metal applications.

Which Blade Is Best for Cutting Aluminum?

The best miter saw blades for cutting aluminum are specifically designed to handle the unique properties of metal, providing clean cuts and durability.

- Carbide-Tipped Blade: This blade features teeth coated with carbide, making it extremely durable and capable of cutting through aluminum with precision.

- Non-Ferrous Metal Blade: Designed specifically for non-ferrous metals like aluminum, these blades have a unique tooth geometry that helps minimize burrs and ensure a smooth finish.

- High-Speed Steel (HSS) Blade: These blades are made from high-speed steel, providing excellent cutting performance on aluminum, although they may dull faster than carbide-tipped options.

- Thin Kerf Blade: A thin kerf design reduces material waste and provides faster cuts, making it ideal for cutting aluminum without compromising on cut quality.

- Aluminum-Specific Blade: These specialized blades are tailored for aluminum cutting and often feature a unique tooth design to enhance chip removal and reduce the risk of binding.

Carbide-Tipped Blade: This blade features teeth coated with carbide, making it extremely durable and capable of cutting through aluminum with precision. The carbide material withstands heat and wear, ensuring longevity and consistent performance even with frequent use.

Non-Ferrous Metal Blade: Designed specifically for non-ferrous metals like aluminum, these blades have a unique tooth geometry that helps minimize burrs and ensure a smooth finish. Their design allows for improved chip clearance, reducing the likelihood of overheating and binding during the cutting process.

High-Speed Steel (HSS) Blade: These blades are made from high-speed steel, providing excellent cutting performance on aluminum, although they may dull faster than carbide-tipped options. HSS blades are typically more affordable but require more frequent sharpening to maintain cutting efficiency.

Thin Kerf Blade: A thin kerf design reduces material waste and provides faster cuts, making it ideal for cutting aluminum without compromising on cut quality. This type of blade is particularly beneficial for projects where precision and efficiency are crucial, as it minimizes the amount of material removed during cutting.

Aluminum-Specific Blade: These specialized blades are tailored for aluminum cutting and often feature a unique tooth design to enhance chip removal and reduce the risk of binding. They ensure that the cut edges are smooth and clean, which is essential for aluminum applications where aesthetics and fit are important.

What Blade Works Best for Stainless Steel Applications?

The best miter saw blades for stainless steel applications include specialized blades designed to handle the hardness and toughness of metal. Here are some recommended types:

- TCT (Tungsten Carbide Tipped) Blades: These blades are highly durable and can cut through stainless steel effectively due to their hardened tips that resist wear.

- Bi-Metal Blades: Made from a combination of metals, these blades offer flexibility and strength, making them ideal for cutting stainless steel without breaking or dulling quickly.

- High-Speed Steel (HSS) Blades: HSS blades maintain sharpness for longer periods and can handle the heat generated during metal cutting, making them suitable for stainless steel applications.

- Diamond Blades: Specifically designed for cutting hard materials, diamond blades provide exceptional performance on stainless steel, offering clean cuts and long-lasting durability.

TCT (Tungsten Carbide Tipped) Blades: These blades feature tungsten carbide tips that are extremely hard and resistant to wear, making them suitable for cutting through stainless steel. Their design allows for smoother cuts and reduced friction, which helps in prolonging the life of the blade while maintaining cutting precision.

Bi-Metal Blades: Bi-metal blades are constructed from two types of metals, typically a flexible steel body and high-speed steel teeth, allowing them to absorb shock and resist breakage while cutting tough materials like stainless steel. They are versatile and can be used for various thicknesses of metal, making them a favorite among professionals for heavy-duty applications.

High-Speed Steel (HSS) Blades: HSS blades are known for their ability to maintain sharpness over extended periods and their resistance to deformation under heat. This characteristic makes them ideal for stainless steel applications, as they provide clean cuts without excessive heating, which can lead to material warping.

Diamond Blades: These blades are embedded with diamond particles that allow them to cut through the hardest materials, including stainless steel, with ease. They are particularly useful for achieving precise and clean cuts, and they tend to last longer than traditional metal-cutting blades, making them a cost-effective choice in the long run.

Related Post: