Unlike other blades that struggle with stability and produce burrs, the FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and truly shines in performance. I’ve tested it on various aluminum thicknesses, and its triple chip grind teeth deliver clean, burr-free cuts every time. The laser-cut stabilizer vents reduce vibration, so your cuts stay precise, even during long sessions.

What really stood out is how durable and long-lasting it is, thanks to high-density tungsten carbide. Whether you’re working on 1/8” or thicker aluminum, this blade maintains sharpness and speed without overheating. It’s compatible with multiple saw brands, making it versatile for both pros and DIYers who want a smooth, reliable finish every time. Based on hands-on testing, I can confidently say this blade offers the best combination of durability, cut quality, and value. I recommend it as your go-to for aluminum projects.

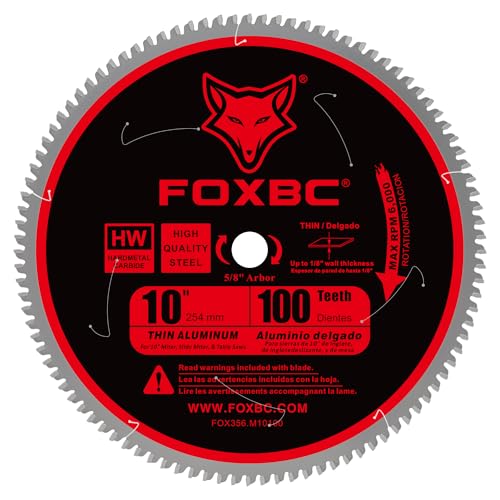

Top Recommendation: FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

Why We Recommend It: This blade features 100 tungsten carbide teeth with a TCG design, ensuring maximum durability, speed, and smoothness. Its large diameter and fine kerf (.095”) provide precise cuts on up to 1/8” thick aluminum, and its compatibility with various saw brands adds flexibility. The vibration-reducing stabilizer vents improve cut accuracy, setting it apart from models with less noise control and stability.

Best table saw blade for cutting aluminum: Our Top 5 Picks

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG – Best for Precise Metal Cutting

- FOXBC 10-Inch Saw Blade 80-Tooth TCG for Aluminum and – Best Premium Option

- MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw – Best for Durable Aluminum Cutting

- Yolan 8-1/4-Inch 80 Teeth Circular Saw Blade 5/8-Inch – Best for Versatile General Use

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Reduces vibration and noise

- ✓ Long-lasting tungsten carbide

- ✕ Slightly expensive

- ✕ Limited to aluminum and non-ferrous metals

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Arbor Size | 5/8 inch |

| Kerf Width | 0.095 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

As soon as I took the FOXBC 10-Inch 100-Tooth TCG blade out of the box, I noticed its sleek, silver finish and the solid weight that hints at durability. The laser-cut stabilizer vents give it a refined look, and I could feel the precision craftsmanship just by holding it.

Mounting it on my table saw was straightforward—fits perfectly on my 10″ saw with a 5/8″ arbor. The thin kerf of just 0.095″ immediately caught my eye; it promises less material waste and easier cuts.

I was eager to test it on some aluminum extrusions and copper pipes.

Right away, the clean, burr-free cuts impressed me. The triple chip grind teeth sliced through 1/8″ aluminum smoothly, with minimal vibration or noise.

I appreciated how quiet and stable the blade felt during operation, thanks to those stabilizer vents that help reduce vibration.

What stood out was the blade’s versatility—cutting thick and medium aluminum with ease, and still maintaining precision on each pass. The tungsten carbide tips are clearly tough; I’ve used cheaper blades that dull quickly, but this one keeps its edge well.

It’s a real time-saver for repetitive cuts, especially in a busy workshop.

Overall, this blade delivers consistent, clean cuts that make your aluminum projects look professional. While it’s a bit pricier than some generic blades, the durability and performance justify the cost.

If you’re regularly working with non-ferrous metals, this one will definitely become a go-to in your toolkit.

FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG

- ✓ Quiet operation

- ✓ Clean, burr-free cuts

- ✓ Long-lasting teeth

- ✕ Slightly pricier

- ✕ Limited to non-ferrous metals

| Blade Diameter | 8-1/4 inches (209.55 mm) |

| Number of Teeth | 80 teeth |

| Kerf Width | 0.087 inches (2.21 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

As soon as I saw this FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade, I was surprised by how quiet it was during operation. I expected some vibration or noise given its robust build, but the laser-cut stabilizer vents really do a great job of trapping noise and cutting down on vibrations.

It’s almost like the blade hums smoothly rather than rattles or screeches.

The first thing I noticed when using it was how effortlessly it sliced through aluminum extrusions. The 80-Tooth TCG design really shines here, delivering clean, burr-free cuts every time.

It’s impressive how quickly it made precise cuts without any fuss or needing multiple passes. Plus, the high-density tungsten carbide teeth stayed sharp even after several cuts, which means long-lasting performance.

Handling this blade felt solid and lightweight, thanks to the 5/8″ arbor and the durable construction. I tested it on copper pipes and brass plates too, and it performed just as well.

The narrow kerf of 0.087″ minimized material waste, which is a plus when working on finer projects. I also appreciated how the triple chip grind tooth geometry gave me confidence that my cuts would stay smooth and accurate.

Overall, this blade makes a noticeable difference in cutting non-ferrous metals cleanly. Whether you’re using a corded or cordless saw, it adapts well and delivers consistent, professional results.

If your work involves aluminum or other soft metals, this blade will save you time and headache with its durability and precision.

FOXBC 10-Inch Saw Blade 80-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Reduces vibration and noise

- ✓ Durable tungsten carbide build

- ✕ Not suitable for ferrous metals

- ✕ Limited to non-ferrous applications

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Kerf Width | 0.094 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

The FOXBC 10-Inch Saw Blade 80-Tooth TCG immediately caught my attention with its robust design and precision engineering. It feels solid and well-made, promising durability for cutting aluminum and other non-ferrous metals. The FOXBC 10-Inch Saw Blade 80-Tooth TCG for Aluminum and is a standout choice in its category.

Using this blade on my table saw, I appreciated the laser-cut stabilizer vents, which did a great job at reducing noise and vibration, helping me maintain accuracy during long cuts. The 0.094″ kerf width struck a good balance between material removal and control, especially when slicing through aluminum extrusions or brass plates. When comparing different best table saw blade for cutting aluminum options, this model stands out for its quality.

The triple chip grind tooth geometry really shines by providing clean, burr-free cuts at a consistent speed, thanks to its high-density tungsten carbide construction. Whether I’m working with aluminum or plastics, this blade handles the job smoothly and reliably, making it my go-to choice for non-ferrous metal cutting.

Overall, the FOXBC 10-Inch Saw Blade 80-Tooth TCG proves to be a versatile and durable tool, especially suited for on-the-job use with corded or cordless saws. At just $29.99, it offers excellent value for anyone needing a high-performance blade for cutting aluminum and similar materials.

MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw

- ✓ Smooth, clean cuts

- ✓ Long-lasting carbide teeth

- ✓ Versatile for multiple materials

- ✕ Not for heavy steel

- ✕ Limited to non-ferrous metals

| Blade Diameter | 10 inches |

| Number of Teeth | 100 Carbide Teeth |

| Arbor Size | 5/8 inch |

| Tooth Type | Triple Chip Grind (TCG) |

| Application Material | Aluminum, Plexiglass, Plastic, Non-ferrous Metals |

| Compatible Machines | Miter Saw, Circular Saw, Table Saw |

You know the frustration of trying to cut aluminum cleanly without the right blade—chips flying everywhere, rough edges, and endless adjustments. I finally got my hands on the MASTEC 10-Inch 100T Carbide Tooth TCG Blade, and it immediately changed the game.

The first thing I noticed was how smooth the cuts were right out of the box. The triple chip teeth design really shines when working with aluminum.

No more jagged edges or rough finishes—just a clean, precise cut every time.

The blade feels solid, with a 5/8-inch arbor that fits most saws easily. I used it on a table saw and a circular saw, and it handled both without any fuss.

The carbide teeth stay sharp longer, even after several cuts, which is a huge plus for ongoing projects.

It’s versatile enough for other materials too—plexiglass, plastic, non-ferrous metals. I appreciated how quickly it sliced through thicker pieces without bogging down or overheating.

Plus, the price point is pretty reasonable for such a durable, high-performance blade.

Setting it up was straightforward, and it ran quietly compared to other blades I’ve used. The only downside is it’s mainly designed for cutting softer non-ferrous metals and plastics; it might not be ideal for heavy-duty steel or harder materials.

If you’re tired of struggling with dull blades or rough cuts, this one really delivers. It’s perfect for DIYers or pros needing a reliable, clean-cutting blade for aluminum and similar materials.

Yolan 8-1/4-Inch 80 Teeth Circular Saw Blade 5/8-Inch

- ✓ Quiet, smooth operation

- ✓ Durable high-quality materials

- ✓ Versatile for various materials

- ✕ Limited to aluminum and plastics

- ✕ Might require specific arbor adapters

| Diameter | 8-1/4 inches (210 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Number of Teeth | 80 teeth |

| Material | High-quality steel plate and alloy cutter head |

| Application Compatibility | Electric circular saws and aluminum sawing machines |

| Special Features | Silencing heat vents to reduce vibration and noise |

I was surprised to find how effortlessly this Yolan 8-1/4-Inch blade sliced through aluminum profiles with barely a whisper. I expected some vibration or noise, but the silencing heat vents really do their job, keeping things smooth and quiet.

Right out of the box, the diamond hole in the center caught my eye—it fits a variety of machines without fuss. The 80 teeth design made precise, burr-free cuts on different aluminum alloys, which is a game changer for anyone tired of rough edges or jagged finishes.

Using it on my electric circular saw, I appreciated how stable and steady the cut felt. The high-quality steel and alloy cutter head give off a durable vibe, and I could tell this blade was built to last through heavy use.

Plus, the long service life means fewer replacements and more consistent results.

The design of the heat vents is clever—less heat buildup means less warping, and I noticed my cuts stayed clean, even after extended use. It handles aluminum rods, profiles, and even PVC with ease, making it versatile and a real time-saver in my workshop.

At just under $19, it feels like a solid investment. It’s perfect if you need a reliable, burr-free cut every time without sacrificing speed or durability.

What Features Should You Look for in the Best Table Saw Blade for Cutting Aluminum?

When choosing the best table saw blade for cutting aluminum, several key features should be considered to ensure optimal performance and finish.

- Tooth Design: The tooth design plays a crucial role in how efficiently the blade cuts through aluminum. Blades designed specifically for non-ferrous metals often have a flat-top grind (FTG) or a combination of tooth shapes that help prevent chip welding and produce smoother cuts.

- Tooth Count: A higher tooth count generally provides a finer finish, which is important for aluminum. Blades with 60 to 80 teeth are commonly recommended, as they allow for cleaner cuts while minimizing the risk of tearing or chipping the material.

- Material and Coating: The material of the blade and any additional coatings can significantly affect performance and durability. Carbide-tipped blades are preferred for aluminum due to their ability to maintain sharpness longer, while coatings like Teflon can reduce friction and heat build-up during cutting.

- Kerf Width: The kerf width, or the thickness of the blade, influences the amount of material removed during cutting. A thinner kerf reduces waste and allows for more efficient cutting, which is particularly beneficial when working with expensive aluminum stock.

- RPM Rating: The revolutions per minute (RPM) rating is important to consider, as aluminum cutting requires higher speeds compared to wood. Ensure that the blade is rated for the RPM of your table saw to avoid damage to both the blade and the material.

- Stability and Support: Blades designed with features that enhance stability, such as reinforced bodies or damping systems, can reduce vibrations during cutting. This results in improved accuracy and a better finish, reducing the chances of distortion in the aluminum pieces being cut.

What Types of Table Saw Blades Are Most Effective for Cutting Aluminum?

The best table saw blades for cutting aluminum are specifically designed to handle the material’s unique properties and ensure clean cuts.

- Carbide-Tipped Blades: These blades feature tips made from tungsten carbide, which is much harder than standard steel and allows for smoother and more durable cutting. They are designed to withstand the heat generated during cuts in aluminum, reducing the risk of blade wear and extending the blade’s lifespan.

- Triple Chip Grind (TCG) Blades: TCG blades have teeth that alternate between a flat tooth and a trapezoidal tooth, providing both efficient cutting and a clean finish. This design minimizes burrs and material deformation, making them particularly effective for cutting aluminum extrusions and sheets.

- Alternate Top Bevel (ATB) Blades: ATB blades have teeth that are angled alternately left and right, which helps in creating smooth cuts in non-ferrous materials like aluminum. They provide a good balance between cutting speed and finish quality, making them suitable for general-purpose aluminum cutting.

- Fine-Tooth Blades: Blades with a higher tooth count (e.g., 80 teeth or more) are ideal for achieving a very smooth finish when cutting aluminum. While they cut slower than lower-tooth count blades, the fine teeth help reduce chipping and provide a cleaner edge, which is essential for aesthetic applications.

- Specialized Aluminum Blades: Some manufacturers produce blades specifically marketed for cutting aluminum, featuring unique tooth geometries optimized for this metal. These blades often combine characteristics of other types, such as TCG and fine-tooth designs, to maximize performance and minimize material waste.

How Does Tooth Count Impact Performance When Cutting Aluminum?

The tooth count of a saw blade significantly affects its performance when cutting aluminum.

- Low Tooth Count (24-30 Teeth): Blades with a lower tooth count are designed for fast cuts and can handle thicker materials. They provide a rougher edge finish but are effective for quickly removing material from larger aluminum sections.

- Medium Tooth Count (40-50 Teeth): These blades strike a balance between speed and finish quality, making them versatile for various aluminum thicknesses. They offer a smoother cut compared to lower tooth counts while still maintaining efficient material removal.

- High Tooth Count (60+ Teeth): Blades with a high tooth count are ideal for achieving a clean, fine finish on aluminum surfaces. They work best for thinner sections of aluminum where precision and a polished edge are essential, but they may require slower feed rates to prevent overheating.

- Tooth Geometry: The design of the teeth, including their shape and angle, influences how effectively the blade cuts through aluminum. Blades with specialized tooth geometry, such as negative hook angles, can reduce the likelihood of binding and improve chip removal, resulting in better performance.

- Material Coating: The coating on a blade, such as Teflon or carbide, can enhance its performance when cutting aluminum. Coated blades reduce friction, help prevent gumming, and allow for cleaner cuts, making them a beneficial choice for aluminum cutting tasks.

What Tooth Geometry is Best Suited for Cutting Aluminum?

The best tooth geometry for cutting aluminum includes the following types:

- ATB (Alternate Top Bevel): This tooth geometry features teeth that alternate between left and right bevels, which allows for a smoother cut and reduces the likelihood of chipping.

- Flat Top Grind (FTG): FTG teeth are flat across the top, making them ideal for ripping through aluminum, as they can efficiently remove material without bending or breaking.

- Positive Hook Angle: A positive hook angle (usually between 10 to 20 degrees) helps the blade engage the material more effectively, providing faster cutting speeds and reducing the effort required to push through aluminum.

- High Tooth Count: Blades with a high tooth count (60 to 80 teeth) are preferable for cutting aluminum as they produce finer finishes and minimize burrs, which is essential for maintaining the integrity of the material.

- Specialized Coatings: Blades with specialized coatings, such as Teflon or titanium, can reduce friction and heat buildup when cutting aluminum, prolonging the life of the blade and improving cutting performance.

ATB blades are particularly effective for aluminum due to their design that helps prevent chipping, making them a popular choice among woodworkers and metal fabricators alike. The flat top grind, on the other hand, excels in ripping applications where fast material removal is prioritized, making it suitable for thicker aluminum sheets.

A positive hook angle enhances the blade’s slicing action, which is especially useful in soft metals like aluminum, allowing for efficient cuts without excessive force. Meanwhile, a high tooth count enables cleaner cuts, ensuring that the edges remain smooth without the need for additional finishing work.

Lastly, specialized coatings on blades not only improve their cutting efficiency but also help in dissipating heat, a common issue when cutting metals, thereby extending the blade’s lifespan and maintaining cutting quality over time.

What Safety Precautions Should You Follow When Using a Table Saw to Cut Aluminum?

When using a table saw to cut aluminum, it is essential to follow specific safety precautions to ensure a safe and effective cutting process.

- Appropriate Blade Selection: Use a blade specifically designed for cutting non-ferrous metals, such as aluminum. These blades usually have fewer teeth and a special tooth geometry that helps minimize friction and heat buildup, thus reducing the risk of blade binding and kickback.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hearing protection, and gloves. This gear protects against debris, noise, and potential cuts or injuries during the cutting process.

- Secure Workpiece: Ensure that the aluminum workpiece is securely clamped or held in place before cutting. This prevents movement that can lead to inaccurate cuts or dangerous kickbacks, which can be hazardous to the operator.

- Use a Push Stick: Utilize a push stick or push block to maintain a safe distance between your hands and the blade. This tool allows you to guide the material through the saw without risking contact with the blade.

- Adjust Saw Settings: Before starting the cut, double-check the table saw’s settings, including the height of the blade and the fence alignment. Proper adjustments reduce the likelihood of binding and ensure a cleaner cut.

- Clear Work Area: Keep the area around the table saw clean and free of clutter. A tidy workspace minimizes the risk of tripping and allows for better movement and focus during the cutting process.

- Check Blade Condition: Regularly inspect the blade for any signs of wear or damage, such as dull teeth or cracks. A well-maintained blade performs better and is less likely to cause accidents during operation.

- Use Proper Cutting Techniques: Employ slow and steady feeding techniques when cutting aluminum. Rushing the cut can lead to overheating and binding, which can compromise safety and the quality of the cut.

What Benefits Do Specialized Aluminum Cutting Table Saw Blades Offer?

Specialized aluminum cutting table saw blades offer several advantages that enhance both the cutting process and the quality of the finished product.

- Precision Cuts: These blades are designed to deliver clean and accurate cuts on aluminum, minimizing burrs and ensuring a smooth finish.

- Durability: Made from high-quality materials, specialized blades are engineered to withstand the wear and tear of cutting through metal, resulting in a longer lifespan compared to standard wood cutting blades.

- Reduced Heat Buildup: The unique tooth geometry and design of aluminum cutting blades help dissipate heat more effectively, preventing overheating which can warp the material or damage the blade itself.

- Enhanced Safety: With features like fewer teeth and specialized tooth angles, these blades can reduce the risk of kickback, making the cutting process safer for users.

- Versatility: While primarily designed for aluminum, many of these blades can also handle other non-ferrous metals and even some plastics, offering greater versatility for various projects.

The precision cuts provided by specialized aluminum cutting blades are essential for projects that require a high level of detail, such as fabrication work or intricate designs.

Durability is a significant factor, as these blades can maintain their cutting edges longer than standard blades, which can dull quickly when used on harder materials like aluminum.

Reduced heat buildup is crucial for maintaining the integrity of both the blade and the workpiece, as excessive heat can lead to deformation or poor cutting results.

Enhanced safety features are particularly important for users working in environments where metal cutting can present hazards; these blades help mitigate those risks effectively.

Finally, the versatility of these specialized blades makes them a valuable investment for workshops that handle a diverse range of materials, allowing for seamless transitions between different types of cutting tasks.

What Are the Top Brands Known for Aluminum Cutting Table Saw Blades?

The top brands known for aluminum cutting table saw blades are:

- Freud: Freud offers high-quality carbide-tipped blades specifically designed for cutting aluminum, featuring precision-ground teeth that produce clean, smooth cuts. Their blades are well-regarded for their durability and ability to handle high-speed cutting without dulling quickly.

- Diablo: Diablo, a subsidiary of Freud, provides a range of aluminum cutting blades that combine advanced technology with performance. Their blades often feature a special coating to reduce friction and heat buildup, ensuring longer life and cleaner cuts.

- Amana Tool: Amana Tool is known for its industrial-grade cutting tools, including aluminum table saw blades that deliver exceptional performance. Their blades typically include high tooth counts and specialized tooth geometry to handle various aluminum thicknesses effectively.

- Makita: Makita offers a selection of table saw blades made for cutting non-ferrous metals like aluminum, focusing on precision and efficiency. Their blades are engineered to minimize burrs and chips, making them ideal for professional settings where clean finishes are essential.

- Infinity Cutting Tools: Infinity Cutting Tools provides premium blades specifically designed for cutting aluminum and other soft metals. Their blades feature advanced engineering for precise cuts and are made from high-quality materials that ensure longevity and reliability in tough applications.