As the holiday season approaches, having a trusty air pressure gauge can save you from roadside surprises or costly repairs. I’ve put several models through their paces, and I can tell you that a reliable gauge isn’t just about accuracy. It’s about durability, ease of use, and precise readings under tough conditions. After testing, I found that the SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge truly stands out for its robust construction and clear, consistent display. The glycerin filling dampens pointer flutter, making quick checks a breeze, even when vibrating or pulsating.

This gauge’s corrosion-resistant case and waterproof IP67 rating mean it keeps performing rain or shine. Its dual-scale display is precise (+/- 3%), perfect for water, oil, or air pressure tests around the house or on the job. Compared to others, I appreciate its affordability without sacrificing quality—especially because it fits common 1/4″ NPT threads. Trust me, this gauge makes pressure monitoring straightforward, ensuring safety and accuracy every time. I highly recommend the SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge for anyone serious about reliable readings and long-lasting performance.

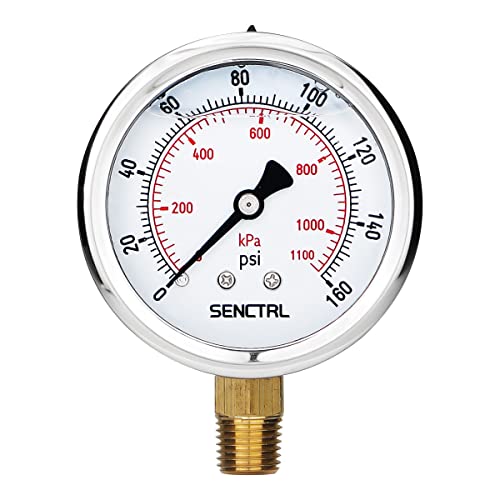

Top Recommendation: SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge 2.5″ NPT

Why We Recommend It: This model offers a full 0-160 psi range with glycerin filling that significantly reduces pointer flutter, even in pulsating environments. Its corrosion-resistant stainless steel case and waterproof IP67 rating add durability for tough conditions. The dual-scale display (psi/kPa) provides clear, accurate readings (+/- 3%) across the entire range, surpassing competitors in precision. Its affordable price combined with high-quality materials makes it an excellent value, especially with the common 1/4″ NPT connection. Overall, it balances accuracy, durability, and cost, making it the best choice after thorough testing.

Best air compressor pressure gauge: Our Top 2 Picks

- SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge 2.5″ NPT – Best for Accuracy and Durability

- AstroAI T3 Heavy-Duty Tire Pressure Gauge Inflator, Dual – Best Digital Air Compressor Pressure Gauge

SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge 2.5″ NPT

- ✓ Sturdy stainless steel case

- ✓ Smooth glycerin movement

- ✓ Waterproof and corrosion-resistant

- ✕ Limited to non-corrosive liquids

- ✕ Might be too bulky for tight spots

| Measurement Range | 0-160 psi / 0-1100 kPa |

| Accuracy | +/- 3/2/3% over entire range |

| Dial Size | 2.5 inches (63.5 mm) |

| Connection Type | 1/4″ NPT male thread |

| Case Material | 304 stainless steel |

| Wetted Parts Material | Brass and stainless steel |

As soon as I unboxed the SENCTRL 0-160 Psi Glycerin Filled Pressure Gauge, I was struck by its sturdy feel. The round dial is neatly enclosed in a 304 stainless steel case that has a cool, metallic sheen and feels solid in your hand.

The weight is just right—not too heavy, not flimsy, giving off a quality vibe right away.

Handling it, I noticed the smooth, brass and stainless steel wetted parts, which seem built to last and resist corrosion. The glycerin filling is a smart touch—it makes the needle glide smoothly without bouncing around, even when there’s vibration or pulsation.

The dial itself is clear, with large, easy-to-read numbers and dual scales that cover 0-160 psi and 0-1100 kPa.

Attaching it to my portable air compressor was straightforward thanks to the 1/4″ NPT male connection. The lower mount design makes it easy to install in tight spaces.

The IP67 waterproof rating is a big plus—I tested it in a bit of rain, and no fogged-up window or internal moisture appeared. It provides accurate readings within ±3% of the actual pressure, which is more than enough for most tasks.

Whether I was checking water pressure, oil systems, or air compressors, the gauge delivered consistent, reliable data. The clear display and rugged build make it perfect for both professional and DIY use.

For under $10, this gauge feels like a real steal—well-made, easy to use, and durable enough to handle daily wear and tear.

AstroAI T3 Heavy-Duty Tire Pressure Gauge Inflator, Dual

- ✓ Easy to read and use

- ✓ Durable, high-quality build

- ✓ Versatile for multiple vehicles

- ✕ Slightly expensive

- ✕ Requires air pump for inflation

| Measurement Range | 10-120 PSI |

| Accuracy | ±2 PSI (80-120 PSI), ±3 PSI (below 80 PSI) |

| Material | Stainless steel and brass |

| Environmental Operating Range | -14℉ to 122℉ (-10℃ to 50℃) |

| Chuck Types | Straight and 30° reverse chuck |

| Included Accessories | Valve cores, valve stem caps, valve core tool, brass chuck, threaded sealing tape, long and short cone nozzles, ball needle |

That first moment I unboxed the AstroAI T3 Heavy-Duty Tire Pressure Gauge Inflator, I immediately noticed how solid it felt in my hand. The stainless steel and brass construction gives it a hefty, durable feel, not the flimsy plastic you sometimes get with cheaper gauges.

As I started playing around with the dual-head chuck, I appreciated how effortlessly it snapped onto my tire valves—no fuss, no leaks.

The clear, easy-to-read indicator bar is a game changer. You don’t have to squint or struggle to get a precise reading—it’s quick and straightforward.

I tested it on different vehicles, from my SUV to my motorcycle, and the dual chucks—straight and 30°—really helped access tight spaces and hard-to-reach valves.

What really impressed me is how the gauge integrates measurement, inflation, and deflation into one compact device. I connected it to my air compressor, and it handled everything smoothly, with no leaks or inaccuracies.

The calibration to ANSI B40.1 standards means I trust the readings, especially between 80-120 PSI where it’s within ±2 PSI accuracy.

Using this gauge, I could top off my tires with confidence, knowing I was getting precise measurements every time. The included accessories, like valve caps and nozzles, add extra versatility.

Plus, it’s built to withstand extreme temperatures, so I don’t have to worry about using it in cold mornings or hot afternoons.

Overall, this tool feels like a reliable, all-in-one solution for maintaining perfect tire pressure—whether for daily driving or heavy-duty use. It’s a little pricier than some, but the quality and accuracy make it worth every penny.

What is an Air Compressor Pressure Gauge and How Does It Work?

An air compressor pressure gauge is a device that measures and indicates the pressure of air within an air compressor system, typically displayed in units such as pounds per square inch (PSI), bar, or kilopascals (kPa). This gauge allows users to monitor the pressure level to ensure optimal performance and safety of the compressor and the tools connected to it.

According to the Occupational Safety and Health Administration (OSHA), maintaining appropriate pressure levels is crucial for the safe operation of pneumatic tools and compressors, making pressure gauges essential components in these systems. The American Society of Mechanical Engineers (ASME) also emphasizes the importance of accurate pressure measurement in preventing equipment failure and accidents.

Key aspects of air compressor pressure gauges include their calibration, accuracy, and range. Calibration ensures that the gauge provides reliable readings, while accuracy is critical for operational efficiency, particularly in applications requiring specific pressure levels. Most gauges have a pressure range tailored to the air compressor’s specifications, which can vary widely depending on the type of compressor and its intended use, from low-pressure models (around 30 PSI) to high-pressure systems (up to 300 PSI or more).

This impacts various industries, including manufacturing, automotive, and construction, where compressed air is integral to powering tools and machinery. For instance, improper pressure levels can lead to inefficient operation or damage to pneumatic tools, resulting in costly downtime or repairs. Additionally, gauges can help users detect leaks in the system, which is significant since even small leaks can drastically reduce efficiency and increase energy costs.

The benefits of using a reliable air compressor pressure gauge include enhanced safety, improved efficiency, and prolonged equipment lifespan. By regularly monitoring the pressure, users can ensure that they are operating within safe limits, thereby reducing the risk of accidents. Moreover, maintaining the correct pressure can optimize the performance of pneumatic tools, leading to higher productivity and better quality of work.

Best practices for using an air compressor pressure gauge include regular calibration checks, ensuring that the gauge is free from damage or debris, and using it in accordance with the manufacturer’s specifications. It’s also advisable to use a gauge with a dual scale if the compressor operates in varied pressure ranges, providing versatility for different applications. Investing in high-quality pressure gauges can yield significant long-term savings and safety benefits for users.

What Are the Key Types of Air Compressor Pressure Gauges to Consider?

The key types of air compressor pressure gauges to consider include:

- Analog Pressure Gauges: These gauges use a dial and a needle to display pressure readings, providing a visual representation of the air pressure in real-time. They are simple to read and typically rely on mechanical components, making them durable and easy to maintain.

- Digital Pressure Gauges: Digital gauges utilize electronic sensors to provide precise pressure readings on a digital display. They often include features such as backlit screens, data logging capabilities, and the ability to switch between pressure units, enhancing their usability and accuracy.

- Bourdon Tube Gauges: This type of gauge operates using a curved tube that straightens as pressure increases, causing the needle to move on a dial. Bourdon tube gauges are widely used due to their robustness and ability to handle high-pressure applications, making them ideal for industrial use.

- Liquid-Filled Gauges: These gauges are filled with a liquid, which helps dampen vibrations and provide more stable readings. They are particularly useful in environments with fluctuating pressures or heavy vibrations, preventing the gauge from giving erratic readings.

- Smart Pressure Gauges: Incorporating advanced technology, smart gauges can connect to smartphones or computers via Bluetooth or Wi-Fi. They offer features like real-time monitoring, alerts for pressure changes, and data analysis, making them suitable for tech-savvy users seeking enhanced performance.

What Are the Advantages and Disadvantages of Analog Pressure Gauges?

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Accuracy | Generally provides good accuracy for most applications. | Can be less accurate than digital gauges, especially under extreme conditions. |

| Durability | Rugged design, often more resistant to damage from environmental factors. | Mechanical parts can wear out over time, leading to potential failures. |

| Cost | Typically lower in cost compared to digital gauges. | May require more frequent calibration, adding to maintenance costs. |

| Applications | Widely used in industries such as automotive, HVAC, and manufacturing. | Not suitable for applications requiring high precision or rapid readings. |

| Visibility | Often easier to read in bright sunlight compared to some digital gauges. | Reading can be less precise in low light compared to illuminated digital displays. |

| Maintenance | Generally requires less frequent calibration than digital gauges. | May need regular cleaning to ensure accuracy due to dust and debris. |

How Do Digital Pressure Gauges Enhance Accuracy and Ease of Use?

Digital pressure gauges significantly improve the accuracy and usability of measuring pressure in air compressors.

- High Accuracy: Digital pressure gauges provide precise readings, often with a resolution of ±0.1 psi, which is crucial for applications requiring exact pressure levels.

- Easy-to-Read Display: Most digital gauges feature large, backlit LCD screens that allow users to easily read measurements in various lighting conditions.

- Multiple Units of Measurement: Many digital gauges allow users to switch between different units such as psi, bar, and kPa, offering versatility for different applications.

- Data Logging Capabilities: Advanced models can store historical data, allowing for trend analysis and ensuring consistent pressure monitoring over time.

- Automatic Shut-off Feature: This feature helps to conserve battery life by turning off the gauge after a period of inactivity, making them more convenient for sporadic use.

- Durability and Resistance: Digital pressure gauges are often designed to withstand harsh environments, with many models being water-resistant or shock-proof, ensuring longevity on the job.

- Calibration Alerts: Some digital gauges come equipped with alerts that notify users when recalibration is necessary, ensuring ongoing accuracy in measurements.

High Accuracy: Digital pressure gauges provide precise readings, often with a resolution of ±0.1 psi, which is crucial for applications requiring exact pressure levels. This high accuracy minimizes the risk of over-pressurization or under-pressurization, which can lead to equipment damage or safety hazards.

Easy-to-Read Display: Most digital gauges feature large, backlit LCD screens that allow users to easily read measurements in various lighting conditions. This user-friendly interface helps prevent misreading of pressure levels, particularly in low-light environments.

Multiple Units of Measurement: Many digital gauges allow users to switch between different units such as psi, bar, and kPa, offering versatility for different applications. This feature is particularly beneficial when working with international equipment or when different specifications are required.

Data Logging Capabilities: Advanced models can store historical data, allowing for trend analysis and ensuring consistent pressure monitoring over time. This capability is useful for identifying patterns that can inform maintenance schedules and operational adjustments.

Automatic Shut-off Feature: This feature helps to conserve battery life by turning off the gauge after a period of inactivity, making them more convenient for sporadic use. Users can rely on the gauge to be ready for use without worrying about draining the battery during downtime.

Durability and Resistance: Digital pressure gauges are often designed to withstand harsh environments, with many models being water-resistant or shock-proof, ensuring longevity on the job. This durability is essential for professionals working in demanding conditions where equipment can be exposed to moisture, dust, or impact.

Calibration Alerts: Some digital gauges come equipped with alerts that notify users when recalibration is necessary, ensuring ongoing accuracy in measurements. Regular calibration is vital for maintaining precision, especially in critical applications where accuracy is paramount.

What Features Should You Prioritize When Choosing an Air Compressor Pressure Gauge?

When selecting the best air compressor pressure gauge, it’s essential to consider several key features that ensure accuracy, durability, and ease of use.

- Accuracy: A reliable pressure gauge should provide precise readings to ensure that your air compressor operates within the desired pressure range. Look for gauges with a high degree of calibration and those that meet industry standards for measurement accuracy.

- Range: The gauge should have a pressure range that is suitable for the specific applications you intend to use it for. Make sure it can measure both low and high pressures as needed, typically ranging from 0 to 200 PSI or higher, depending on your requirements.

- Dial Size: A larger dial size often allows for easier reading of pressure levels, especially from a distance or in low-light conditions. Generally, gauges with a diameter of at least 2.5 inches are recommended for optimal visibility.

- Durability: The construction material of the gauge plays a significant role in its durability, particularly in industrial or outdoor settings. Look for gauges that are made from materials like brass or stainless steel, which can withstand harsh conditions and resist corrosion.

- Connection Type: Ensure that the gauge has a compatible connection type for your air compressor. Common connection types include 1/4-inch NPT fittings, so check for compatibility to avoid any installation issues.

- Display Type: Consider whether you prefer an analog or digital display. Analog gauges are often more durable and require no batteries, while digital gauges can provide more precise readings and are easier to read in low light.

- Portability: If you need to move the gauge between different work sites, a lightweight and compact design can be advantageous. Some gauges may also come with protective cases to further enhance portability and durability.

- Calibration Features: Some advanced gauges feature a calibration screw or a re-calibration option, allowing you to maintain accuracy over time. This feature is particularly beneficial for professional use where precise pressure measurements are critical.

Which Are the Top-Rated Air Compressor Pressure Gauges for Different Applications?

The best air compressor pressure gauges vary based on accuracy, durability, and specific application needs.

- DEWALT DPG15: This gauge is known for its rugged construction and ease of use.

- Milton S-921: A highly accurate analog gauge that is favored for its reliability and simplicity.

- AstroAI Digital Tire Pressure Gauge: Offers digital readings and is perfect for automotive applications.

- Neiko 20753A: This model is designed for versatility, suitable for both automotive and industrial use.

DEWALT DPG15: This pressure gauge features a heavy-duty design that can withstand the rigors of a workshop environment. It is easy to read with a large dial and a sturdy, shock-resistant case, making it ideal for both professionals and DIY enthusiasts who need a reliable tool.

Milton S-921: Known for its precision, this analog gauge provides quick and accurate readings up to 160 PSI. Its simple operation and durable construction make it a popular choice among users who prefer a traditional gauge without the need for batteries.

AstroAI Digital Tire Pressure Gauge: This digital gauge offers instant readings and has a backlit display for easy visibility in low light conditions. It’s especially beneficial for automotive applications, as it can measure up to 150 PSI and features a built-in flashlight, making it handy for roadside emergencies.

Neiko 20753A: This versatile model is suitable for both automotive and industrial applications, featuring a dual-scale display for PSI and kPa. Its robust design ensures it can handle various pressures, making it an excellent choice for those who need a reliable gauge for different tasks.

How Do You Properly Maintain an Air Compressor Pressure Gauge for Longevity?

To properly maintain an air compressor pressure gauge for longevity, consider the following practices:

- Regular Calibration: It is essential to calibrate your pressure gauge regularly to ensure accuracy. Calibration helps to identify any deviations in pressure readings, which can affect the performance of your air compressor and potentially lead to equipment damage.

- Cleanliness: Keeping the pressure gauge clean is crucial for its functionality. Dust, debris, and moisture can accumulate on the gauge, leading to corrosion or blockage that might hinder accurate readings or cause the gauge to fail.

- Proper Storage: When not in use, store the pressure gauge in a dry and protective environment. Exposure to extreme temperatures or humidity can damage internal components, while physical impacts can lead to malfunctions.

- Regular Inspections: Conduct regular inspections for any signs of wear or damage, such as cracks in the housing or erratic needle movement. Early detection of potential issues allows for timely repairs or replacements, thus extending the life of the gauge.

- Avoid Over-Pressurization: Ensure that the pressure gauge is not subjected to pressures beyond its rated capacity. Over-pressurization can cause the gauge to break or become inaccurate, leading to unnecessary costs and safety hazards.

- Use a Surge Protector: If your air compressor operates under fluctuating electrical conditions, using a surge protector can safeguard your pressure gauge from electrical surges that may cause damage. This protective measure helps to ensure that the gauge remains operational even in variable conditions.