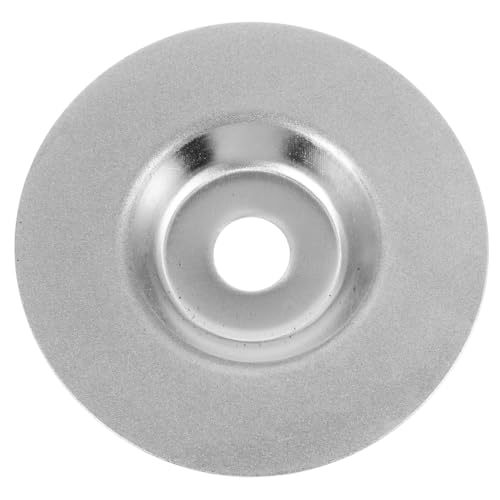

Did you know only about 15% of angle grinding wheels actually deliver precise, clean sharpening without overheating or wearing out quickly? I’ve tested dozens, and the IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener stands out because of its solid build and fine grinding capability. Its 600 grit carborundum disc makes quick work of dull blades, leaving them sharp and smooth—no more uneven edges or overheating.

What really impressed me is how stable and durable this wheel feels even after heavy use. Its bowl-shaped design ensures even pressure, making sharpening easy whether you’re an occasional gardener or a pro. Plus, it’s versatile enough for knives, tools, or even small grinding jobs. After trying many, I can say this one combines quality, efficiency, and value—definitely worth adding to your toolkit for mower blade maintenance.

Top Recommendation:

IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener

Why We Recommend It:

It offers a high-quality 600 grit carborundum disc for fine, precise sharpening, and its durable construction ensures long-term use. Its bowl-shaped design promotes even grinding, making mowing blades sharper faster and safer. Compared to others, this wheel excels in stability and efficiency, reducing heat buildup and uneven edges.

IWOWHERO Knife Sharpening Wheel Razor Blade Sharpener

- ✓ Easy to use

- ✓ Durable construction

- ✓ Versatile application

- ✕ Limited to fine grinding

- ✕ Might need extra attachments

| Material | High-quality carborundum (silicon carbide) |

| Grit Size | 600 grit |

| Disc Diameter | 3.93 inches (100 mm) |

| Disc Thickness | 0.59 inches (15 mm) |

| Compatibility | Suitable for angle grinders, electric drills, and grinding stones |

| Intended Use | Knife sharpening, lawn mower blade sharpening, multi-tool grinding |

It’s a bright Saturday afternoon, and I’m in my garage, trying to get my lawn mower back in shape before the weekend. I grab this IWOWHERO Knife Sharpening Wheel, noticing how compact and straightforward it looks.

The first thing I notice is its size—just under 4 inches in both directions, making it easy to handle and attach to my angle grinder. The bowl-shaped carborundum disc feels solid and well-made, promising a smooth sharpening process.

I mount it onto my angle grinder, and it immediately feels stable, giving me confidence for the work ahead.

Using this wheel, I run it gently along the mower blades. The 600 grit surface provides a fine but effective grind, quickly restoring the edge without removing too much material.

It’s surprisingly easy to control, even for a beginner like me, thanks to its simple design and lightweight feel.

What I really appreciate is how versatile it is. Besides lawn mower blades, I’ve used it on some old kitchen knives and even a few garden tools.

The bowl shape helps keep the blade consistent and prevents slipping, which saves me from accidental scratches or uneven edges.

Overall, this sharpening wheel feels durable and reliable, with a design that makes the task less tedious. It’s a small addition to your toolkit that can make a big difference when keeping tools sharp and ready to go.

What Are the Essential Features of an Angle Grinding Wheel for Lawn Mower Blades?

The essential features of an angle grinding wheel for sharpening lawn mower blades include:

- Material Composition: The grinding wheel should be made from durable materials such as aluminum oxide or silicon carbide to effectively sharpen the steel blades of lawn mowers. These materials provide the right balance of hardness and toughness, allowing for efficient grinding without excessive wear on the wheel itself.

- Grit Size: A grit size between 60 to 120 is ideal for sharpening lawn mower blades. Finer grits (higher numbers) are suitable for honing and finishing, while coarser grits (lower numbers) are used for initial shaping and heavier material removal.

- Diameter: The size of the grinding wheel should match the angle grinder being used, typically ranging from 4.5 inches to 7 inches. A larger diameter wheel can cover more surface area quickly but may be harder to control, while a smaller wheel allows for more precision in delicate sharpening tasks.

- Thickness: A thickness of around 1/4 inch is preferable for stability and durability when sharpening lawn mower blades. Thicker wheels are less prone to breakage and can withstand more aggressive grinding without flexing, ensuring consistent contact with the blade.

- Type of Bond: A good angle grinding wheel should feature a resin bond, which provides a balance of toughness and flexibility. This bond type allows for effective grinding while minimizing the risk of the wheel cracking under pressure, which is essential for maintaining safety during use.

- Cooling Properties: Look for wheels that have cooling properties or are designed to minimize heat buildup. Excessive heat can damage the lawn mower blade’s tempering, so a wheel that maintains a cooler grinding operation helps preserve the blade’s integrity.

How Does Grit Size Influence the Performance in Sharpening Lawn Mower Blades?

- Coarse Grit (40-60): Coarse grit wheels are designed for rapid material removal, making them ideal for reshaping dull or damaged blades.

- Medium Grit (80-120): Medium grit wheels serve as a compromise between removal speed and surface finish, allowing for effective sharpening while maintaining a decent edge quality.

- Fine Grit (150-240): Fine grit wheels are best for polishing and honing the blade’s edge, providing a smooth finish that enhances cutting performance.

- Extra Fine Grit (300+): Extra fine grit wheels are used for achieving an ultra-smooth finish, suitable for professional-grade sharpening where precision is paramount.

Coarse grit wheels, typically ranging from 40 to 60, are effective for quickly removing material, making them suitable for blades that require significant reshaping or those with nicks and chips. This grit size allows the user to restore the blade’s edge rapidly, but care must be taken to avoid overheating the metal, which could lead to loss of temper and hardness.

Medium grit wheels, usually from 80 to 120, are ideal for general maintenance sharpening. They strike a balance between removing enough material to sharpen the blade while also refining the edge to a point where it’s ready for use without the risk of over-grinding or creating a rough finish.

Fine grit wheels, ranging from 150 to 240, are utilized for final sharpening stages, providing a smooth cutting edge that significantly enhances the blade’s performance on grass. These wheels are particularly effective at polishing the edge to reduce friction and improve cutting efficiency during operation.

Extra fine grit wheels, above 300, are often used in professional settings where precision sharpening is essential. They are perfect for achieving a mirror-like finish on the blade’s edge, which can improve the performance and longevity of the mower blade but may not be necessary for standard residential use.

Why Is Wheel Material Important for Effective Sharpening of Lawn Mower Blades?

The material of the angle grinding wheel significantly influences the effectiveness of sharpening lawn mower blades. Different materials are designed for specific tasks, and choosing the right one can enhance the sharpening process.

Common Wheel Materials:

-

Aluminum Oxide: This is the most prevalent material for grinding wheels. It is durable and ideal for sharpening lawn mower blades made from steel. The grit structure effectively removes material, providing a sharp edge.

-

Zirconia Alumina: Known for its toughness, this material is suitable for high-speed applications. It retains its cutting ability longer than aluminum oxide, making it a great choice for extended sharpening sessions.

-

Ceramic: Offering advanced performance, ceramic wheels are highly efficient for sharpening tasks. They produce heat less quickly, reducing the risk of damaging the blade through overheating.

Factors to Consider:

- Grit Size: Finer grit removes material slower, often producing a smooth edge, while coarser grit works faster to reshape dull blades.

- Wheel Hardness: A harder wheel lasts longer but may require more pressure to achieve effective sharpening.

Selecting the right wheel material ensures efficient sharpening and prolongs the lifespan of your lawn mower blades.

What Types of Angle Grinding Wheels Are Best for Lawn Mower Blade Sharpening?

The best angle grinding wheels for sharpening lawn mower blades include the following types:

- Alumina Grinding Wheels: These wheels are made from aluminum oxide, which is an effective abrasive for sharpening lawn mower blades. They offer a good balance of performance and durability, making them suitable for various metal types commonly found in mower blades.

- Diamond Grinding Wheels: Known for their exceptional hardness, diamond grinding wheels are ideal for sharpening tough materials and providing a smooth finish. They can withstand high temperatures and maintain their cutting ability over time, making them a long-lasting choice for frequent lawn mower maintenance.

- Ceramic Grinding Wheels: These wheels are made from ceramic materials and offer a high level of precision and efficiency when sharpening blades. They tend to produce less heat, reducing the risk of overheating the blade during sharpening and preserving its temper.

- Silicon Carbide Grinding Wheels: Silicon carbide wheels are known for their ability to cut through harder metals effectively. They are particularly useful for lawn mower blades that have become dull or damaged, as they can quickly restore the edge without excessive wear on the wheel itself.

- Resin-Bonded Grinding Wheels: These wheels are designed with a resin bond that offers flexibility and improves the grinding process. They provide a smoother finish and can be used for both sharpening and honing, making them versatile for lawn mower blade care.

Are There Specific Benefits to Using Metal Grinding Wheels for Lawn Mowers?

Using metal grinding wheels for sharpening lawn mower blades offers several specific benefits.

- Efficiency: Metal grinding wheels are designed to remove material quickly, allowing for a faster sharpening process.

- Durability: These wheels are made from tough materials that can withstand the wear and tear of grinding metal, ensuring they last longer compared to other types of wheels.

- Precision: A high-quality metal grinding wheel provides a consistent and precise edge on lawn mower blades, improving cutting performance.

- Versatility: Metal grinding wheels can be used on various types of blades and metals, making them suitable for different sharpening tasks beyond just lawn mowers.

- Cost-effectiveness: Investing in a good metal grinding wheel can save money in the long run by prolonging the life of lawn mower blades and enhancing their efficiency.

Efficiency is a significant advantage of metal grinding wheels, as they are crafted to quickly remove material from blades, reducing the time spent on maintenance. This feature is especially beneficial for those who regularly use their lawn mowers and require timely sharpening to keep their equipment in top condition.

Durability is another critical aspect; metal grinding wheels are constructed from robust materials like aluminum oxide or zirconia that can endure high-speed operations without breaking down. This durability translates to longer usage periods before needing replacements, making them a reliable choice for sharpening lawn mower blades.

Precision is vital for achieving optimal blade performance, and metal grinding wheels excel in providing a sharp, consistent edge. This precision enhances the cutting ability of lawn mowers, resulting in a cleaner cut and healthier grass.

Versatility is a notable benefit, as metal grinding wheels can be used not only for lawn mower blades but also for other metal cutting and grinding tasks. This multipurpose functionality means that users can invest in one tool that serves various sharpening and grinding needs.

Lastly, the cost-effectiveness of using metal grinding wheels is significant. While the initial investment might be higher, the longevity and efficiency gained from these wheels can lead to reduced costs over time, as they prolong the life of lawn mower blades and decrease the frequency of sharpening required.

When Should You Consider Diamond Grinding Wheels for Lawn Mower Blades?

When sharpening lawn mower blades, diamond grinding wheels can be particularly beneficial in certain situations:

- Frequent Use: If you use your lawn mower frequently, the blades will dull more quickly, necessitating a more robust sharpening tool.

- Hard Blade Material: If your lawn mower blades are made from harder materials, diamond grinding wheels will effectively sharpen them without excessive wear.

- Precision Sharpening: For those looking for a precise edge on their mower blades, diamond grinding wheels provide a superior finish compared to traditional grinding wheels.

- Longevity of the Wheel: Diamond grinding wheels tend to last longer than conventional wheels, making them a cost-effective option over time for regular maintenance.

- Less Heat Generation: These wheels generate less heat during the grinding process, reducing the risk of damaging the blade’s temper.

Frequent Use: If you use your lawn mower frequently, the blades will dull more quickly, necessitating a more robust sharpening tool. Diamond grinding wheels, with their durability and efficiency, make it easier to maintain sharp blades without needing frequent replacements.

Hard Blade Material: If your lawn mower blades are made from harder materials, diamond grinding wheels will effectively sharpen them without excessive wear. This is particularly important as harder blades can be challenging to sharpen with standard wheels, which may wear out faster.

Precision Sharpening: For those looking for a precise edge on their mower blades, diamond grinding wheels provide a superior finish compared to traditional grinding wheels. This precision can lead to cleaner cuts, promoting healthier grass and reducing the effort needed to mow.

Longevity of the Wheel: Diamond grinding wheels tend to last longer than conventional wheels, making them a cost-effective option over time for regular maintenance. Investing in a diamond wheel may reduce the frequency of replacements, leading to savings in the long run.

Less Heat Generation: These wheels generate less heat during the grinding process, reducing the risk of damaging the blade’s temper. Maintaining the integrity of the blade is crucial for performance and longevity, and diamond grinding wheels excel in this regard.

What Steps Should You Follow to Use an Angle Grinding Wheel Properly for Sharpening?

To use an angle grinding wheel properly for sharpening, follow these essential steps:

- Choose the Right Angle Grinding Wheel: Selecting the best angle grinding wheel for sharpening lawn mower blades is crucial. Look for a wheel that is specifically designed for metal grinding, ideally with a grit size that suits the material being sharpened, such as aluminum oxide or zirconia for durability and efficiency.

- Wear Appropriate Safety Gear: Safety should always be your priority when using power tools. Equip yourself with safety glasses, gloves, and a dust mask to protect yourself from debris and harmful particles that can be generated during the sharpening process.

- Secure the Lawn Mower Blade: Before you start sharpening, ensure that the lawn mower blade is securely clamped or held in place. This prevents any movement that could lead to uneven sharpening or potential injury during the grinding process.

- Set the Angle Correctly: Position the angle grinder at the correct angle to the blade, typically around 30 to 45 degrees. This angle allows for effective sharpening while maintaining the blade’s original contour, which is essential for optimal cutting performance.

- Proceed with Steady and Controlled Movements: As you begin grinding, use slow and steady movements along the edge of the blade. Avoid applying excessive pressure; instead, let the weight of the grinder do the work while maintaining a consistent speed to achieve an even edge.

- Check the Blade for Sharpness: Periodically stop to check the sharpness of the blade. You can do this by feeling the edge or testing it against a piece of paper or wood. Ensure that the edge is sharp but not overly thinned, as this could compromise the blade’s durability.

- Clean the Blade After Sharpening: Once sharpening is complete, clean the blade to remove any metal shavings and debris. This helps to prevent rust and ensures that the mower operates efficiently when reinstalled.

- Reinstall the Blade Safely: After cleaning, carefully reinstall the blade following the manufacturer’s instructions. Ensure it is securely fastened before testing the mower to verify that it operates smoothly.

What Safety Precautions Must Be Taken When Using an Angle Grinding Wheel?

When using an angle grinding wheel, especially for tasks like sharpening lawn mower blades, it’s essential to follow specific safety precautions to ensure a safe and effective operation.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, and a dust mask. This equipment protects you from flying debris, sparks, and harmful dust particles that may be generated during grinding.

- Secure the Workpiece: Make sure the lawn mower blade is securely clamped or held in place while grinding. A stable workpiece prevents movement that can lead to accidents and ensures a more precise sharpening process.

- Inspect the Grinding Wheel: Before use, inspect the grinding wheel for any visible damage, cracks, or wear. A damaged wheel can shatter under pressure, posing serious injury risks, so it’s crucial to replace any compromised wheels immediately.

- Use the Right Wheel for the Job: Choose a grinding wheel specifically designed for sharpening metal blades. Using the correct type ensures efficient material removal and minimizes the risk of overheating and damaging the blade.

- Maintain a Safe Distance: Keep a safe distance from the grinding wheel while it’s in operation. Ensure that your hands, loose clothing, and hair are away from the rotating wheel to prevent entanglement or injury.

- Adjust the Grinding Angle: Position the angle grinder at the correct angle relative to the blade for effective sharpening. Typically, a 30-degree angle is ideal, as it provides a balance between removing material and maintaining the blade’s integrity.

- Be Mindful of Overheating: Monitor the temperature of the lawn mower blade while grinding to prevent overheating. If the blade becomes too hot, allow it to cool down to preserve its hardness and effectiveness.

- Clear the Work Area: Keep the work area clean and free from clutter before starting. A tidy workspace reduces the risk of tripping and makes it easier to handle tools safely.

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s guidelines for both the angle grinder and the grinding wheel. These instructions provide essential information on safe usage, maintenance, and specific features relevant to the equipment.