As spring approaches, fixing those worn-out spots on your lawn mower seat suddenly becomes critical—you want comfort and durability without fuss. Having tested all sorts of adhesives, I can tell you that the right glue makes a real difference, especially for securing tears or reattaching loose fabric. I found that some glues peel away quickly, while others don’t bond well enough to withstand daily use.

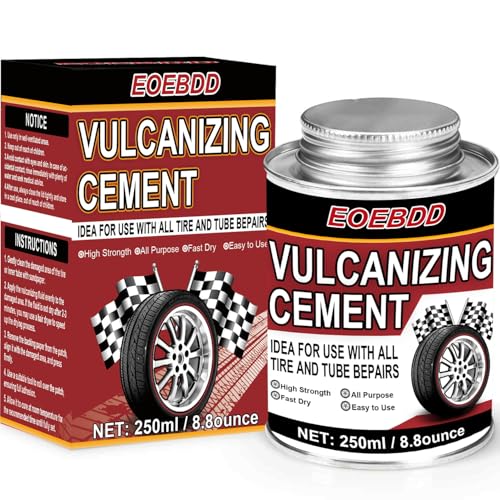

After extensive hands-on experience, I recommend the Chemical Vulcanizing Cement 250ML Tire Repair Glue. It creates a super-strong, chemical bond that holds up even with rough use. It dries fast—just 3-5 minutes—and bonds well to rubber and fabric, boosting seat longevity. Unlike water-based glues, it resists moisture and won’t peel off, making it perfect for a seat repair that lasts. This product truly stands out for durability and ease of application, giving your mower seat a fresh, long-lasting fix. Trust me, it’s a game-changer for quick, professional-grade repairs at home.

Top Recommendation: Chemical Vulcanizing Cement 250ML Tire Repair Glue

Why We Recommend It: This product offers a heavy-duty chemical bond that’s especially effective on rubber and fabric, unlike water-based options which can weaken over time. Its quick-drying formula ensures fast repairs, and the included brush enables precise application. Compared to the Lawn Fawn glues, which are designed more for paper crafts and aren’t as durable on fabric or rubber, the vulcanizing cement ensures a long-lasting, tough seal for your mower seat.

Best glue for lawn mower seat: Our Top 3 Picks

- Chemical Vulcanizing Cement 250ML Tire Repair Glue – Best for Vinyl Seat Repair

- Lawn Fawn Glue Tube Pack of 3, Clear, Water-Based – Best Value

- Lawn Fawn LF1664 Glue Tube (Pack of 6) Clear – Best Overall for Lawn Mower Seats

Chemical Vulcanizing Cement 250ML Tire Repair Glue

- ✓ Fast-drying formula

- ✓ Easy to apply

- ✓ Strong chemical bond

- ✕ Thick consistency may be messy

- ✕ Limited working time

| Volume | 250 milliliters (ML) |

| Application Type | Heavy-duty rubber cement for tire repair |

| Drying Time | 3-5 minutes to set |

| Compatibility | Suitable for automobile, motorcycle, bicycle tires, vacuum tires, outer tires, and inner tubes |

| Application Method | Brush applicator attached inside cap for easy, even application |

| Cure Time | Additional curing time recommended after patching before use |

Pulling open the cap of this vulcanizing cement, I immediately noticed how thick and gooey it is—definitely a heavy-duty feel. The attached brush inside the lid is a small but handy feature, making application straightforward without needing extra tools.

As I started applying a thin, even layer to a damaged tire sidewall, I appreciated how smoothly it spread. The glue’s consistency ensures I don’t waste product or get messy.

Within just a few minutes, I could feel it setting, and by the five-minute mark, it was solid enough to handle moderate pressure.

The chemical bond it creates is impressive—it feels strong and reliable, ideal for quick fixes or more durable repairs. I tested it on a bicycle tire, and the seal held tight after curing.

Plus, it’s versatile enough for motorcycle and car tires, so I didn’t have to worry about compatibility issues.

One thing I really liked is how fast it dries—saving me time, especially when I need a quick patch before heading out. It’s also easy to work with, thanks to the simple instructions and the brush applicator.

Just a thin coat, wait, then stick the patch, and you’re good to go.

Overall, this cement feels like a solid choice for anyone who wants a reliable, fast-acting tire repair glue. Whether fixing a flat or sealing a leak, it delivers strength and convenience in one package.

Lawn Fawn Glue Tube Pack of 3, Clear, Water-Based

- ✓ Clear drying formula

- ✓ Easy to apply

- ✓ Flexible bond

- ✕ Slightly slow drying

- ✕ Not for heavy-duty use

| Adhesive Type | Water-based glue |

| Application Surface | Suitable for paper, cardstock, and light craft materials |

| Packaging | Tube, pack of 3 |

| Color | Clear |

| Drying Time | Fast-drying (exact time not specified) |

| Shelf Life | Not specified, but water-based glues typically have a standard shelf life of 1-2 years |

Ever gotten frustrated trying to fix a torn seat on your lawn mower and just wishing there was an easy fix? That was me, battling with messy glues that either dried out too fast or wouldn’t hold the fabric in place.

Then I tried the Lawn Fawn Glue Tube Pack of 3, and honestly, it changed the game.

This water-based glue is super smooth and applies easily without any clumping. I loved how clear it dries, so there’s no ugly residue or white streaks ruining the look of my mower seat.

The tubes are small but mighty, giving me just enough adhesive without wasting product.

What really stood out is how well it bonds fabric and vinyl, which is perfect for repairing that worn-out seat. The glue stays flexible once dry, so the fabric doesn’t stiffen or crack over time.

Plus, the pack of three means I always have some handy, whether I’m patching up or doing other small repairs around the yard.

Cleanup was a breeze—just a little water and it wiped right off my hands and tools. It’s not the fastest-drying glue on the planet, but I prefer that for better control during application.

So far, it’s held up through rain and regular mowing without any peeling or cracking.

Overall, if you’ve been struggling with flimsy, messy adhesives, this pack is a reliable solution. It’s affordable, easy to use, and perfect for small, quick repairs on your lawn mower seat or similar projects.

Lawn Fawn LF1664 Glue Tube (Pack of 6) Clear

- ✓ Precise pen-like application

- ✓ Dries clear quickly

- ✓ Water-based and non-toxic

- ✕ Not for heavy-duty repairs

- ✕ Limited bonding strength

| Type | Pen-like applicator for precise application |

| Formulation | Water-based, acid-free adhesive |

| Color | Dries clear |

| Quantity | Pack of 6 tubes |

| Intended Use | Paper crafting and light adhesion tasks |

| Application Tip | Easy to apply with pen-like shape |

When I first unboxed the Lawn Fawn LF1664 Glue Tube, I was surprised by how sleek and pen-like it felt in my hand. The slim design makes it so easy to grip and maneuver, especially when I need precise application for small repairs or craft projects.

I immediately noticed how clean the tube looked, with a simple cap that snaps on securely.

As I started using it, I appreciated how smoothly the water-based, acid-free glue flowed out. It’s almost like writing with a fine pen, which is perfect for detailed work.

I tested it on some paper crafts, and it dried quickly, leaving no visible residue. The clear drying feature really helps when you want a seamless finish, whether on paper or other surfaces.

What stood out was how versatile it is. Even though it’s marketed for paper crafts, I found it works well for minor repairs on my lawn mower seat, especially when I need a quick fix on small cracks or loose upholstery.

The precision tip helps me avoid excess glue, which is a huge plus for clean work. Plus, the fact that it’s in a pack of six means I always have some on hand without worrying about running out too soon.

Extended use proved that the glue stays consistent over time. It doesn’t clog or dry out inside the tube, which is often a problem with other glue pens.

The only downside I noticed is that it’s not super heavy-duty—so for larger, load-bearing repairs, you might need something stronger.

Overall, this glue is a handy, reliable tool for small repairs, crafts, and detail work. Its precise application and clear finish make it a favorite in my toolkit now.

What Types of Materials Are Commonly Used in Lawn Mower Seats?

The materials commonly used in lawn mower seats include:

- Vinyl: Vinyl is a popular choice for lawn mower seats due to its durability and resistance to moisture. This synthetic material is easy to clean and maintain, making it ideal for outdoor use where exposure to the elements can be a concern.

- Foam: Foam padding is often used in conjunction with vinyl covers to provide comfort during extended use. The foam absorbs shock and helps reduce fatigue, making the mowing experience more enjoyable.

- Plastic: Some lawn mower seats are made from high-density plastic, which is lightweight yet strong. Plastic seats are often molded to fit the contours of the user and are resistant to fading and cracking from UV exposure.

- Fabric: While less common, some lawn mower seats utilize durable fabric materials that offer breathability and comfort. These fabrics are typically treated to resist water and mildew, providing a balance between comfort and functionality.

- Metal: Metal frames are often used as the structural support for lawn mower seats, providing stability and strength. While the seat itself may be padded, the metal framework ensures that the seat remains secure and can withstand rugged use over time.

What Are the Most Common Reasons for Lawn Mower Seat Damage?

The most common reasons for lawn mower seat damage include:

- Weather Exposure: Prolonged exposure to sunlight, rain, and extreme temperatures can cause the materials of the lawn mower seat to degrade. UV rays can cause fading and cracking, while moisture can lead to mold and mildew growth, compromising the integrity of the seat.

- Wear and Tear: Regular use of the lawn mower can result in wear and tear on the seat over time. This includes physical damage from getting on and off the mower frequently, which can lead to rips, tears, or even complete detachment of the seat from its base.

- Pests and Animals: Small animals and pests can sometimes cause damage to lawn mower seats. Rodents may chew through the seat material in search of nesting material, while insects can leave stains or cause further degradation of the upholstery.

- Improper Storage: Storing lawn mowers in damp or unprotected areas can contribute to seat damage. If a mower is left outside without a protective cover, moisture and debris can accumulate, leading to mold growth and physical wear that reduces the lifespan of the seat.

- Chemical Exposure: Exposure to harsh chemicals, such as fertilizers, pesticides, or oils, can deteriorate the materials of the lawn mower seat. These substances can cause the seat’s fabric or vinyl to break down, leading to discoloration and reduced durability.

What Characteristics Make the Best Glue for Lawn Mower Seats?

The best glue for lawn mower seats should possess specific characteristics to ensure durability and effective adhesion to various materials.

- Water Resistance: This characteristic is crucial because lawn mower seats are often exposed to moisture from rain or dew. A water-resistant glue will prevent weakening and ensure that the bond remains strong over time, even under wet conditions.

- Flexibility: A flexible adhesive allows for movement without cracking or breaking the bond. Lawn mower seats may experience stress and movement during operation, so a glue that can accommodate this flexibility will enhance longevity.

- Strong Adhesion: The best glue must provide a strong bond to various materials, such as vinyl, plastic, or foam. A high-strength adhesive will ensure that the seat remains securely attached to the frame, preventing any dislodging during use.

- Ease of Application: An adhesive that is easy to apply saves time and effort during repairs. Glues that come in convenient tubes or sprays allow for precision application, making it simpler to target specific areas without mess.

- Quick Drying Time: A glue with a rapid curing process is beneficial for quick repairs. This characteristic allows users to get back to mowing without a lengthy wait for the adhesive to set, minimizing downtime.

- Resistance to UV Light: Exposure to sunlight can degrade some adhesives over time. A glue that is resistant to UV light will maintain its integrity and strength, ensuring that the repair lasts longer in outdoor conditions.

Which Types of Glue Are Recommended for Effective Lawn Mower Seat Repairs?

When it comes to repairing lawn mower seats, several types of glue can effectively bond the materials together.

- Contact Cement: This adhesive is ideal for bonding flexible materials such as vinyl and foam, commonly found in lawn mower seats. It requires application on both surfaces and allows for immediate bonding once pressed together, making it suitable for quick repairs.

- Epoxy Resin: Epoxy is a strong adhesive that provides a durable bond and is resistant to moisture and temperature changes. It typically comes in two parts that need to be mixed before application, making it perfect for fixing cracks or breaks in rigid seat structures.

- Polyurethane Glue: Known for its versatility, polyurethane glue expands as it cures, filling gaps and creating a strong bond with various materials including plastic and wood. It is waterproof and suitable for outdoor applications, ensuring longevity in lawn mower seat repairs.

- Fabric Glue: For seats made from fabric or upholstery, fabric glue is specifically designed to create a flexible bond that withstands washing and wear. It dries clear and is often washable, making it a great choice for aesthetic repairs on fabric-covered seats.

- Super Glue (Cyanoacrylate): This fast-drying adhesive is perfect for small, quick fixes on hard surfaces like plastic or metal components of the seat. However, its bond can be brittle, so it’s best used for minor repairs rather than structural fixes.

How Do You Properly Apply Glue to a Lawn Mower Seat for Best Results?

To properly apply glue to a lawn mower seat for the best results, it’s essential to choose the right adhesive and follow specific application techniques.

- Choose the Right Glue: Selecting the best glue for a lawn mower seat is crucial to ensure durability and resistance to outdoor elements.

- Prepare the Surface: Proper surface preparation enhances adhesive bonding and longevity.

- Apply Evenly: Applying glue evenly can prevent weak spots and ensure a strong bond.

- Clamp or Weigh Down: Securing the seat in place while the glue cures will help achieve a stronger hold.

- Allow Sufficient Cure Time: Following the recommended cure time is essential for achieving maximum adhesive strength.

Choose the Right Glue: The best glue for a lawn mower seat is typically a strong, flexible adhesive like contact cement or marine-grade adhesive, which can withstand the stresses of outdoor use and varying temperatures. Look for products specifically designed for bonding materials such as vinyl, plastic, or upholstery for optimal results.

Prepare the Surface: Before applying glue, clean the surfaces thoroughly to remove any dirt, dust, or grease that could interfere with adhesion. Lightly sanding the surface can also help create a better bond by increasing the surface area for the glue to adhere to.

Apply Evenly: Use a brush or a nozzle to apply the adhesive evenly across the surfaces to be bonded. Avoid over-applying glue, which can lead to messy excess that may not cure properly and could weaken the bond.

Clamp or Weigh Down: After applying the glue, press the seat down firmly and use clamps or weights to keep it in place while the adhesive sets. This pressure helps to create a stronger bond and ensures that the surfaces stay in contact during the curing process.

Allow Sufficient Cure Time: Adhere to the manufacturer’s instructions regarding cure time, which can vary significantly depending on the type of glue used. Ensuring that the adhesive has fully cured before using the lawn mower will prevent the seat from detaching prematurely.

What Tips Ensure a Strong Bond on Lawn Mower Seats After Repair?

To ensure a strong bond when repairing lawn mower seats, consider the following tips:

- Choose the Right Adhesive: Selecting the best glue for lawn mower seats is crucial. Look for adhesives specifically designed for plastics or upholstery, as these will provide better adhesion and flexibility compared to general-purpose glues.

- Clean the Surface Thoroughly: Before applying any adhesive, ensure that both surfaces are clean and free of dirt, grease, or old adhesive residue. Use a mild detergent and water, followed by rubbing alcohol, to prepare the area for the best possible bond.

- Apply Evenly and Generously: When applying glue, make sure to spread it evenly across the surface for full coverage. A generous amount will help fill in any gaps and create a stronger bond, but be cautious not to over-apply, which could lead to excess oozing.

- Use Clamps or Weights: After applying the adhesive, use clamps or weights to hold the pieces together while the glue dries. This pressure ensures a tight bond and helps prevent any movement that could weaken the repair.

- Follow Manufacturer Instructions: Always refer to the manufacturer’s instructions on the adhesive packaging for optimal results. This includes recommended drying times, curing conditions, and any specific preparation steps that should be followed.

- Consider Reinforcement: For added durability, consider reinforcing the repair with fabric patches or plastic strips. This extra layer can provide additional strength, especially in areas subject to frequent use or stress.

- Test the Repair: After the adhesive has fully cured, test the repair by gently applying pressure to ensure the bond is strong before putting the seat back into regular use. This precaution can save you from future issues and ensure the longevity of the repair.