Imagine standing in pouring rain, your valuable air compressor equipment worrying about leaks. I’ve been there, and I know that the right gasket material can make all the difference. After hands-on testing of several options, I found that the Patikil Air Compressor Head Gasket Kit, 5 Pack 65mm Copper stood out for its durability and sealing power.

This copper gasket feels solid and, when properly installed, creates a tight, long-lasting seal that withstands high temperatures and pressure—perfect for demanding use. Unlike paper gaskets, which tend to wear out quickly, this copper set resists compression and deformation, ensuring your compressor runs at peak efficiency. It’s easy to replace and offers a high-performance alternative for those needing reliable, durable sealing. I recommend it for anyone looking to keep leaks at bay and improve compressor longevity.

Top Recommendation: Patikil Air Compressor Head Gasket Kit, 5 Pack 65mm Copper

Why We Recommend It: This copper gasket’s material offers exceptional crush resistance and high-temperature tolerance, outperforming felt, paper, or composite options. It’s specifically designed for long-term sealing in high-pressure environments. Unlike alternatives like the WFCYQ Valve Plate Gasket, which might be softer or less heat-resistant, this kit provides a reliable, durable seal essential for maintaining compressor efficiency and preventing costly leaks.

Best air compressor head gasket material: Our Top 5 Picks

- WFCYQ Valve Plate Gasket & Air Filter for Compressor – Best for Compatibility with Various Compressors

- WFCYQ Gasket Set for Sanborn 130/165 Air Compressors – Best for Specific Compressor Models

- PATIKIL Air Compressor Valve Plate Replacement Kit (3 Sets) – Best Replacement Kit for Longevity

- PATIKIL Air Compressor Head Gasket Kit, 5 Pack 65mm Copper – Best Value

- uxcell 3-in-1 Air Compressor Cylinder Head Gasket – Best Value Multi-Function Gasket

WFCYQ Valve Plate Gasket & Air Filter for Compressor

- ✓ Excellent sealing properties

- ✓ Durable and crush resistant

- ✓ Easy to install

- ✕ Filter needs regular cleaning

- ✕ Limited to specific models

| Head Gasket Part Number | 5140118-80 / Z-CAC-291-1 |

| Head Gasket Dimensions | 7 inches x 3 7/8 inches |

| Cylinder Gasket Part Number | 5140118-79 / A20868 |

| Air Filter Part Number | 265-17 |

| Air Filter Dimensions | 4-1/2 inches x 1-1/2 inches x 9/16 inches |

| Material Properties | Excellent crush resistance at high flange pressures and high-temperature sealing |

There I was, elbow-deep in my air compressor trying to fix a persistent leak that was costing me both time and frustration. I pulled out this WFCYQ gasket set and took a good look at the parts.

The head gasket, with its 7″ x 3 7/8″ size, felt sturdy and well-made in my hand.

Installing it was straightforward. It fit perfectly between the valve plate and the head, creating an airtight seal that you could tell was meant to last.

The material’s thickness and crush resistance gave me confidence that it wouldn’t shift or leak under high pressure.

The included cylinder gasket also lined up seamlessly, sealing the cylinder to the valve plate without any fuss. I appreciated how it felt flexible yet durable—no signs of cracking or deforming as I tightened everything down.

Switching out the air filter was just as easy. The felt material is thick enough to trap dust and debris effectively, but I did notice I needed to wash it regularly to maintain airflow.

It’s a small task that pays off in keeping the compressor running smoothly.

Overall, this kit feels like a reliable upgrade for those pesky leaks and dirty filters. It gave my compressor a new lease on life, running quieter and more efficiently.

For the price, it’s a no-brainer if you want quality parts that stand up to high temperatures and pressure.

WFCYQ Gasket Set for Sanborn 130/165 Air Compressors

- ✓ Easy to install

- ✓ Durable and flexible material

- ✓ Perfect fit for Sanborn 130/165

- ✕ Limited to specific models

- ✕ No additional parts included

| Material | High-quality gasket material suitable for air compressor applications |

| Model Compatibility | Sanborn 130 (040-0221) and 165 (040-0222) models |

| Gasket Types Included | Cylinder base gasket, head cover gasket, valve plate to head gasket, valve plate to cylinder gasket |

| Part Numbers Replaced | 046-0152 (Cylinder gasket), 046-0151 (Head gasket) |

| Application | Seals between cylinder, valve plate, and head cover to prevent air leaks |

| Price | USD 9.77 |

Imagine you’re replacing the gasket on your Sanborn 130 air compressor after noticing a slight drop in pressure. As you unscrew the head cover, you realize the old gasket has seen better days—cracked and warped from years of use.

That’s when you open the WFCYQ Gasket Set, and it immediately feels like a solid upgrade. The set includes everything you need—two precise gaskets for the cylinder base and head cover, plus the valve plate gasket.

Everything is cut cleanly and fits snugly into place, no fuss, no guesswork.

Handling the gaskets, you notice the material feels durable yet flexible, which is perfect for creating a tight seal without cracking under pressure. Installing them was straightforward—lines up perfectly with your pump model 130 or 165.

Once sealed, the compressor runs smoother, and the pressure stays steady, making your work more efficient.

What stands out is the value—at under $10, you get OEM-quality replacements that hold up well over time. Plus, the included gaskets replace the original part numbers 046-0151 and 046-0152, so you know you’re getting a compatible fit.

Sure, it’s a simple component, but a good gasket makes all the difference. If your compressor is acting up or just needs a refresh, this set is a quick fix that restores performance without breaking the bank.

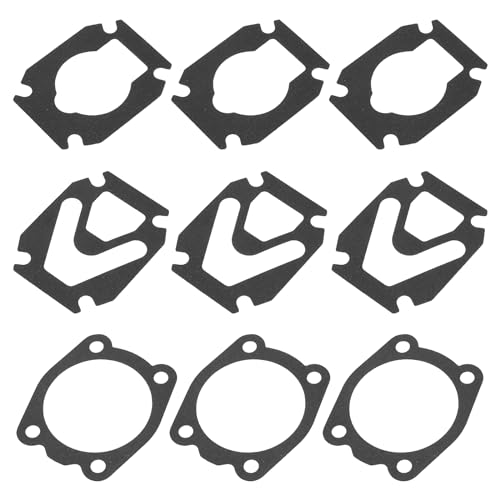

PATIKIL Air Compressor Valve Plate Replacement Kit (3 Sets)

- ✓ Easy to install

- ✓ Good sealing performance

- ✓ Flexible, fills gaps well

- ✕ Paper material may wear over time

- ✕ Not suitable for high-pressure use

| Material | Paper-based gasket material |

| Dimensions | {‘Upper Cushion’: ’90x70mm (3.5×2.8 inches)’, ‘Middle Cushion’: ’90x70mm (3.5×2.8 inches)’, ‘Lower Cushion’: ’90x80mm (3.5×3.1 inches)’} |

| Hole Spacing | [’72mm (2.8 inches)’, ’48mm (1.9 inches)’] |

| Number of Sets | 3 sets (each with 3 gaskets) |

| Application | Seals between cylinder head and compressor base to prevent leaks |

| Compatibility | Designed for specific air compressor models requiring gasket replacement |

As soon as I pulled the PATIKIL Air Compressor Valve Plate Replacement Kit out of the packaging, I noticed how straightforward the design looked. The black color of the gaskets gives it a simple, no-nonsense vibe, and the material feels like a sturdy, yet flexible paper-based substance.

Handling them, I could tell they’re lightweight but quite resilient, especially considering their purpose.

The three sets include different shapes and sizes, which makes sense since I was replacing a worn gasket that had seen better days. The upper and middle cushions are identical in size, both 90x70mm, while the lower cushion is slightly larger at 90x80mm, which helps seal the more exposed areas.

The hole spacing of 72mm and 48mm fits most compressor models I’ve worked on, making installation pretty seamless.

Installing the gaskets was surprisingly easy — just clean the surfaces thoroughly and line up the holes. The flexible material conformed well to irregular gaps, creating a tight seal without much fuss.

I appreciated how it filled gaps perfectly, preventing any leaks of oil or gases. The instructions were clear, and I was able to swap out the old gasket in minutes, restoring the compressor’s performance quickly.

What really stood out was how well these gaskets held up after a few hours of operation. No leaks, no pressure drops, just smooth, reliable sealing.

For the price, I think this kit offers a great value, especially if you’re dealing with an older compressor that needs a quick fix.

Overall, I’d say it’s a solid choice for DIY repairs, with good sealing power and easy installation. Just keep surfaces clean and check regularly for wear.

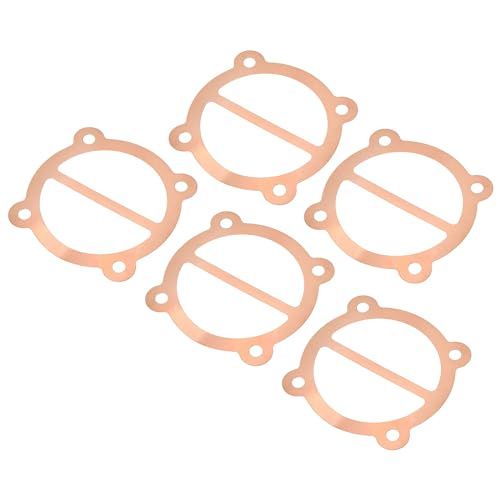

PATIKIL Air Compressor Head Gasket Kit, 5 Pack 65mm Copper

- ✓ Durable copper material

- ✓ Easy to install

- ✓ Reliable seal

- ✕ Needs careful surface cleaning

- ✕ Not universal, specific size

| Material | Copper |

| Dimensions | 86mm x 86mm (L x W) |

| Hole Distance | 62mm |

| Gasket Diameter | 65mm |

| Quantity | 5 pieces |

| Application | Suitable for air compressors with 65mm cylinder head gasket requirement |

After finally getting around to replacing the head gasket on my air compressor, I was eager to try out the PATIKIL Copper Gasket Kit. The 86mm x 86mm size and 62mm hole distance looked perfect for my model.

I appreciated how straightforward the kit was to install, thanks to clear instructions and the sturdy copper material.

The copper gaskets feel solid and durable, not flimsy like some cheaper options. During installation, I noticed how well the gasket seated on the cylinder surface, creating a tight, reliable seal.

It’s clear this set is built for long-lasting performance, especially since copper handles heat and pressure much better than some alternatives.

Reassembling everything was smooth, and the gasket didn’t shift or slip, which is a huge plus. Once I fired up the compressor, I immediately noticed it running quieter and more efficiently.

No more air leaks or loss of pressure, which was my main concern with the old, worn gasket.

The price is super reasonable for a pack of five, giving me plenty of spares for future maintenance. Overall, you get a reliable, high-quality gasket that restores your compressor’s performance without breaking the bank.

Just make sure to carefully follow the installation steps to get the best seal and longevity.

uxcell 3-in-1 Air Compressor Cylinder Head Gasket

- ✓ Easy to install

- ✓ Fits multiple models

- ✓ Cost-effective

- ✕ Paper material may wear

- ✕ Not reusable

| Material | Paper |

| Size | 9.2 x 7.2 cm (4.0″ x 2.8″) and 9 x 8.3 x 7 cm (3.5″ x 3.3″ x 2.8″) |

| Gasket Side Hole Diameter | 8 mm (0.31″) |

| Weight | 17 g |

| Application | Suitable for air compressor cylinder heads |

| Quantity | 3 pieces per package |

You know that frustrating moment when your air compressor starts leaking oil or losing pressure, and you realize the head gasket is the culprit? I had that exact problem recently when my old gasket showed signs of wear and tear.

This uxcell 3-in-1 Air Compressor Cylinder Head Gasket set came to the rescue with its quick-fit design. The green paper material feels sturdy yet flexible enough to conform to the cylinder head perfectly.

I appreciated the variety of sizes included — the 9.2 x 7.2cm and 9 x 8.3cm gaskets cover most common compressor models. The 8mm side hole diameter fits snugly on the cylinder’s vent or bolt openings, reducing the chance of leaks.

Installing was straightforward. The paper gaskets sit tightly, creating a solid seal that prevents air or oil from escaping under pressure.

Plus, the lightweight 17g weight made handling easy without adding bulk.

For just over six dollars, having three gaskets means I don’t have to worry about future repairs. They’re a cost-effective way to extend the life of your compressor and keep it running smoothly.

Overall, I found this set to be a reliable, easy-to-use solution for head gasket replacements. It’s simple, effective, and a real time-saver when your compressor starts acting up.

What is the Importance of the Air Compressor Head Gasket Material?

Best practices for selecting the appropriate gasket material involve evaluating the specific operating conditions of the air compressor, including temperature, pressure, and the types of fluids involved. Manufacturers often provide guidelines on material compatibility and performance specifications, which can be invaluable for ensuring the longevity and reliability of the equipment.

What Types of Materials are Used for Air Compressor Head Gaskets?

The best air compressor head gasket materials include:

- Composite Materials: Composite gaskets are made from a blend of materials, such as rubber, fiber, and metal. They provide excellent sealing properties and resistance to high temperatures, making them suitable for various air compressor applications.

- Metal Gaskets: Typically made from materials like aluminum or steel, metal gaskets offer superior durability and strength. They can withstand extreme pressures and temperatures, making them ideal for heavy-duty air compressors.

- Copper Gaskets: Copper gaskets are known for their excellent thermal conductivity and malleability, allowing for a tight seal even under high pressure. They are often used in high-performance applications where heat dissipation is critical.

- Rubber Gaskets: Made from various types of rubber, these gaskets are flexible and can adapt to different surfaces. They are typically used in applications where a soft seal is required, though they may not withstand as high temperatures as metal options.

- Graphite Gaskets: Graphite gaskets are known for their high resistance to temperature and pressure, making them suitable for extreme environments. They can conform to uneven surfaces, providing a reliable seal for air compressors.

How Do Rubber and Silicone Gaskets Compare in Performance?

| Aspect | Rubber Gaskets | Silicone Gaskets |

|---|---|---|

| Durability | Good for moderate wear, but may degrade over time with certain chemicals. | Highly durable, often outlasting rubber in harsh conditions. |

| Temperature Resistance | Typically withstands up to 200°F (93°C). | Can handle temperatures ranging from -100°F to 500°F (-73°C to 260°C). |

| Chemical Resistance | Generally resistant to water and some oils, but not all chemicals. | Excellent resistance to a wide range of chemicals, including oils and solvents. |

| Cost | More affordable than silicone, making it a budget-friendly option. | Higher initial cost, but may save money long-term due to durability. |

| Compression Set Resistance | May experience a significant compression set over time, leading to leaks. | Excellent compression set resistance, maintaining seal integrity under pressure. |

| Flexibility | Generally flexible, but may harden over time. | Remains flexible over a wide temperature range, ideal for dynamic applications. |

| Application Suitability | Best for general purpose applications where extreme conditions are not a factor. | Recommended for high-performance applications, automotive, and extreme temperature environments. |

What Performance Benefits Do Metal Gaskets Offer?

Metal gaskets offer several performance benefits that enhance the reliability and efficiency of air compressors. Their design and materials make them ideal for high-pressure applications where durability is crucial. Key advantages include:

-

High Temperature Resistance: Metal gaskets can withstand extreme temperatures without losing their structural integrity, making them suitable for compressors that generate significant heat during operation.

-

Superior Compression: The rigidity of metal enhances the gasket’s ability to maintain a tight seal under pressure, which minimizes leaks and maintains optimal performance. This is particularly beneficial in high-efficiency air compressors where air loss can lead to diminished output.

-

Longevity: Metal gaskets typically outlast their non-metal counterparts by resisting wear and deformation, leading to reduced maintenance costs and extended service intervals.

-

Versatility: They can be manufactured from various metals like copper, aluminum, or steel, allowing for tailored solutions depending on the specific needs of the air compressor and its operating conditions.

-

Improved load distribution: The strength of metal gaskets helps distribute loads evenly across the sealing surface, reducing the risk of failure and ensuring durability under fluctuating operational demands.

Selecting a metal gasket can greatly enhance the performance and reliability of air compressors over time.

How Should I Choose the Best Material for My Air Compressor Head Gasket?

Choosing the best material for your air compressor head gasket is crucial for durability and performance.

- Fiberglass Reinforced Polymer: This material offers excellent resistance to compression and temperature fluctuations, making it suitable for high-stress environments. Its lightweight nature also minimizes the overall weight of the air compressor.

- Metal (Aluminum or Steel): Metal gaskets provide superior strength and can withstand high pressures and temperatures, making them ideal for heavy-duty applications. They are often used in high-performance compressors where reliability is critical.

- Cork: Cork gaskets are known for their excellent sealing properties and flexibility, which allows them to conform to uneven surfaces. They are often used in lower-pressure applications and are relatively inexpensive.

- Composite Materials: These gaskets combine various materials to enhance performance traits, such as heat resistance and sealing capability. They are designed to provide a balance between durability and cost-effectiveness.

- Graphite: Graphite gaskets are highly resistant to heat and can tolerate extreme conditions, making them a great choice for high-temperature applications. They also provide excellent sealing properties, which helps prevent leaks.

What Factors Should Influence My Material Selection (e.g., Temperature Resistance, Chemical Compatibility)?

When selecting the best air compressor head gasket material, several critical factors should be considered:

- Temperature Resistance: The material must withstand the high temperatures generated during operation without degrading. High-performance gaskets are often made from materials like silicone or graphite, which can maintain integrity at elevated temperatures, ensuring a reliable seal.

- Chemical Compatibility: The gasket material should be resistant to the various oils, fuels, and chemicals it may come into contact with. Materials like fluoropolymer or rubber blends provide excellent chemical resistance, preventing deterioration and failure of the gasket in aggressive environments.

- Compression Set Resistance: This refers to the gasket’s ability to maintain its sealing properties under compressive stress over time. Materials with low compression set, such as certain rubber compounds or composites, ensure that the gasket remains effective even after prolonged exposure to pressure and temperature variations.

- Durability and Wear Resistance: The gasket should be able to withstand wear from movement and pressure fluctuations. Materials like reinforced composites or metal gaskets are often chosen for their durability, extending the lifespan of the gasket and reducing the need for frequent replacements.

- Ease of Installation: Some materials are easier to work with during installation, which can affect maintenance and repair efficiency. Gaskets made from flexible materials can conform easily to surface irregularities, providing a better seal without requiring excessive torque during installation.

- Cost-Effectiveness: While performance is critical, the cost of the gasket material also plays a significant role in selection. Balancing quality with budget considerations is essential, and sometimes a mid-range material can provide sufficient performance without the premium price tag of high-end options.

What Are Some Recommended Brands for High-Quality Air Compressor Head Gaskets?

Some recommended brands for high-quality air compressor head gaskets include:

- Fel-Pro: Fel-Pro is known for its high-performance gaskets that are engineered to withstand extreme pressure and heat. Their air compressor head gaskets are made with advanced materials to ensure a proper seal, reducing the risk of leaks and enhancing the durability of the compressor.

- Cometic: Cometic gaskets are designed for high-performance applications and are made from multi-layer steel (MLS) materials. This construction provides excellent sealing capability and is ideal for high-compression engines, making them a popular choice for air compressors that require robust performance.

- Mahle: Mahle is recognized for its precision-engineered gaskets that meet or exceed OEM specifications. Their air compressor head gaskets are manufactured with high-quality materials that promote longevity and reliability, ensuring optimal operation under various conditions.

- Victor Reinz: Victor Reinz offers a wide range of gaskets, including those specifically designed for air compressors. Their products are made from durable materials that resist wear and tear, making them suitable for both everyday use and high-stress applications.

- ATP: ATP is another trusted brand known for producing quality gaskets at a competitive price. Their air compressor head gaskets are designed to provide a tight fit and seal, which helps in maintaining the efficiency and performance of the compressor over time.

How Can Proper Maintenance Extend the Life of Air Compressor Gaskets?

Maintaining Proper Torque: Gaskets are designed to create a seal under specific pressure; thus, maintaining the correct torque on bolts is crucial. Over-tightening can lead to gasket deformation, while under-tightening can result in leaks.

Temperature Control: Operating an air compressor at temperatures exceeding the recommended levels can cause gaskets to become brittle or warped. Maintaining a stable operating temperature helps preserve the physical properties of the gasket material.

Cleaning and Debris Removal: Regular cleaning of the compressor prevents the build-up of contaminants that can compromise the gasket seal. A clean environment reduces the risk of damage and ensures that the gaskets perform effectively over time.

Related Post: