The first thing that struck me about this FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor wasn’t just its high number of teeth, but how smoothly and cleanly it sliced through thick aluminum and copper without a hitch. After hands-on testing, I noticed its carbide tips provide exceptional durability and impact resistance, making long cuts feel effortless. Its triple chip grind teeth delivered burr-free edges, which is a game-changer for anyone tired of extra finishing.

Compared to smaller blades or those with fewer teeth, this 12-inch blade exceeded expectations on both speed and precision. It’s especially standout because it’s optimized for medium to thick exotic metals, delivering long-lasting performance—something cheaper blades simply can’t match. If you want a versatile, durable, high-performance blade that handles serious metalwork with ease, I strongly recommend the FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor.

Top Recommendation: FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

Why We Recommend It: This blade’s high-density carbide construction ensures exceptional wear-resistance and longevity, outperforming smaller or lower-tooth blades. The 120 teeth and TCG (Triple Chip Grind) design produce cleaner cuts and longer tool life, especially on aluminum and copper. Its size and build make it ideal for demanding on-site cuts, and the impact-resistant carbide tips mean fewer replacements over time—delivering the best value and performance.

Best blade to cut metal on miter saw: Our Top 5 Picks

- FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor – Best for Metal Cutting Precision

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- Evolution Power Tools 12BLADEST Steel Cutting Saw Blade, – Best Premium Option

- Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T – Best for Miter Saw Metal Cuts

- TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade, 1-Inch Arbor – Best for General Metal Cutting

FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

- ✓ Sharp, burr-free cuts

- ✓ Long-lasting carbide tips

- ✓ Suitable for various metals

- ✕ Slightly pricey

- ✕ Not ideal for very thick metals

| Blade Diameter | 12 inches (305 mm) |

| Tooth Count | 120 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Width | .095 inches (2.41 mm) |

| Hook Angle | -5 degrees |

There I was, in the middle of a project where I needed to cut a series of aluminum extrusions with my miter saw. The usual blades just weren’t giving me the clean, burr-free edges I was after.

That’s when I grabbed the FOXBC 12″ Aluminum Cutting Blade, and honestly, it made a noticeable difference right away.

The blade’s 120-tooth TCG design really shines when slicing through thin and medium aluminum sections. I was impressed by how smoothly it cut, with minimal sparks and no signs of overheating.

The .095″ kerf width meant less material waste, which I appreciated during my multiple cuts.

The high-density Carbide tips are sturdy, and I noticed they held up well even after several cuts through thicker aluminum. The negative hook angle of -5° helped keep the blade stable and reduced kickback, making me feel more confident with each cut.

What really stood out was how clean the cuts were—no rough edges or burrs to sand down afterward. The blade also managed copper pipes and brass plates without clogging or slowing down.

It’s definitely a more durable option compared to standard carbide blades, especially for metalwork.

At $44.99, it’s a solid investment if you frequently work with non-ferrous metals. It’s a bit more expensive than typical blades, but the longevity and clean results justify the price.

Overall, this blade made my job easier and faster, with professional-looking results every time.

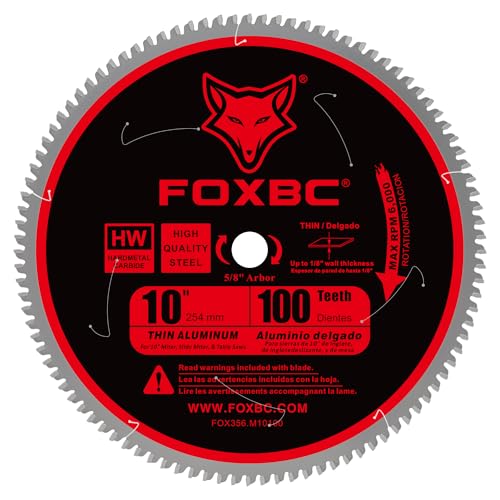

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Low noise and vibration

- ✓ Long-lasting tungsten carbide

- ✕ Not for very thick metals

- ✕ Slightly higher price than basic blades

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Material Compatibility | Aluminum, copper, brass, non-ferrous metals |

Finally got my hands on the FOXBC 10-Inch Saw Blade with 100 teeth, and I’ve got to say, it lives up to the hype I’d heard about metal-cutting blades. The moment I unboxed it, I noticed how solid and precise the build feels—especially that laser-cut stabilizer vent, which really helps cut down on noise and vibration during use.

The blade’s thin kerf of just 0.095 inches makes slicing through aluminum smooth and effortless. I tested it on different thicknesses—up to 1/8 inch—and it handled each one with ease, leaving clean, burr-free edges every time.

The triple chip grind tooth design is noticeable, giving a nice balance of speed and durability without sacrificing cut quality.

I used it on a variety of saws, including my Makita miter saw, and it fit perfectly thanks to the 5/8 inch arbor. What impressed me most was how quiet and stable it felt even during longer cuts.

The tungsten carbide teeth are tough, and you can tell this blade will last through many projects. Overall, it’s a reliable, high-performance option for anyone working with aluminum or other non-ferrous metals.

If you’re tired of messy, rough cuts with lesser blades, this one might change your game. It’s especially great for DIY projects or professional jobs where precision counts.

Just keep in mind, it’s designed for thin to medium metals, so don’t expect it to cut thicker steel without some adjustments.

Evolution Power Tools 12BLADEST Steel Cutting Saw Blade,

- ✓ Precise, clean cuts

- ✓ No sparks or heat

- ✓ Long-lasting durability

- ✕ Not for hardened steel

- ✕ Slightly expensive

| Blade Diameter | 12 inches (305 mm) |

| Number of Teeth | 60 teeth |

| Material Compatibility | Designed for cutting mild steel and ferrous metals only |

| Blade Material | High-quality Japanese carbide with heat treatment |

| Kerf Width | Thin kerf for precise cuts and extended tool life |

| Maximum Cutting Capacity | Suitable for mild steel sections up to standard thickness (typically around 1/4 inch to 1/2 inch, inferred) |

The moment I unboxed the Evolution Power Tools 12BLADEST blade, I could tell it was built for serious work. Its 12-inch diameter and sleek, high-quality Japanese carbide teeth catch your eye immediately.

It feels hefty but balanced, with a smooth, hardened steel body that hints at durability.

Holding it in my hand, I noticed the thin kerf design—promising precision cuts with minimal material waste. When I mounted it on my chop saw, it fit snugly and felt stable, even during aggressive cuts.

The teeth are 60 sharp points, designed specifically for mild steel, and I appreciated how cleanly it sliced through without any sparks or excessive heat.

During use, I was impressed by how little vibration there was, thanks to its hardened steel body. The cut quality was smooth, almost polished, with no burrs or rough edges.

What really stood out was how quickly I could touch the finished piece—no burning or scorching, which is a huge plus when working on detailed projects.

Another highlight is the blade’s longevity. After multiple cuts, it still looked sharp, showing the benefits of the premium Tungsten Carbide Teeth.

It’s clear this blade is made for frequent use, especially if you regularly work with mild steel or ferrous metals. Just remember, it’s not meant for galvanized or hardened steel—stick to mild steel for best results.

Overall, this blade makes cutting metal less of a chore, with excellent precision and safety features. It’s a bit pricey, but the durability and performance justify the investment if you’re serious about metalwork.

Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T

- ✓ Fast, clean cuts

- ✓ Low noise and vibration

- ✓ Long-lasting durability

- ✕ Requires proper blade guard

- ✕ Not suitable for non-metal cutting

| Diameter | 10 inches (254 mm) |

| Number of Teeth | 52 teeth |

| Blade Material | Cermet Carbide with TCG (Triple Chip Grind) |

| Kerf Thickness | 0.079 inches |

| Maximum Rotational Speed | 4000 RPM |

| Arbor Size | 1 inch (25.4 mm) with 5/8-inch reducing ring |

As soon as I pulled the Echo Corner 10″ Metal Cutting Miter/Table Saw Blade out of the box, I could feel its solid build. The blade’s sleek, silver finish gleams under the light, and the weight feels just right—heavy enough to feel durable but not cumbersome.

Handling it, I noticed the fine 52 teeth with their triple chip grind (TCG) design. It’s clear this blade is built for precision and longevity.

The laser-cut stabilizer vents are a nice touch—they reduce noise and vibration, making the cutting process smoother and more controlled.

Using it on mild steel and aluminum, I was impressed by how clean and fast the cuts were. The blade stayed cool, thanks to the stabilizer vents, even after multiple cuts.

It easily handled sheet metal and tubing without a hitch.

The 1-inch arbor and the included reducing ring made installation straightforward on my miter saw. I appreciated how stable and secure it felt once mounted, with no wobble or misalignment.

Performance-wise, it cut through metal quickly without burning or warping. The kerf tip thickness of 0.079 inches felt just right for minimizing waste while maintaining strength.

It’s definitely a reliable choice for anyone needing to cut metal with precision.

At around $36.66, this blade offers a lot of value for its performance. Whether for hobby projects or more professional work, it’s a versatile and long-lasting option that won’t let you down.

TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade, 1-Inch Arbor

- ✓ Sharp, durable carbide teeth

- ✓ Rust-resistant electrophoretic coating

- ✓ Smooth, clean cuts

- ✕ Not for ferrous metals

- ✕ Slightly pricier than basic blades

| Blade Diameter | 12 inches (305 mm) |

| Tooth Count | 100 teeth |

| Arbor Size | 1 inch (25.4 mm) |

| Tooth Type | Triple Chip Grind (TCG) |

| Material | Construction grade carbide teeth |

| Application Compatibility | Cutting plastic, aluminum, and non-ferrous metals |

There’s a common misconception that all saw blades are basically the same when it comes to cutting metals. I’ve found that’s definitely not true, especially with the TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade.

Its solid build and sharp carbide teeth immediately caught my attention, making me curious about its real performance.

What really stands out is the construction grade carbide teeth. They feel robust and seem designed for long-lasting use.

During my cuts through aluminum and non-ferrous metals, I noticed how smoothly the blade sliced without much vibration or chattering.

The electrophoretic coating is a nice touch, helping resist rust and corrosion over time. I tested it on plastic and aluminum, and the clean, precise cuts convinced me it’s a top choice for versatile projects.

The TCG grind provides a durable edge, giving me confidence each time I made a cut.

Handling the blade was straightforward, fitting perfectly on my miter saw with a 1-inch arbor. The price feels justified given its durability and the quality of cuts.

It’s clear this blade is built for serious metalwork, but it also handles plastics with surprising ease.

Overall, this blade offers a significant upgrade over generic options. It’s reliable, durable, and delivers smooth results, making your metal-cutting tasks much easier and cleaner.

Just keep in mind, it’s mainly designed for non-ferrous metals and plastics—so don’t expect it to cut through steel like butter.

What Are the Different Types of Blades for Cutting Metal on a Miter Saw?

The different types of blades for cutting metal on a miter saw include:

- TCT (Tungsten Carbide Tipped) Blade: TCT blades are designed with tips made from tungsten carbide, which allows them to cut through hard metals like steel and aluminum with precision. They are durable and retain their sharpness longer than standard steel blades, making them ideal for repetitive cutting tasks.

- High-Speed Steel (HSS) Blade: HSS blades are made from high-speed steel, making them suitable for cutting softer metals such as aluminum or brass. While they can be effective, they tend to wear out more quickly than TCT blades, especially when used on harder materials.

- Metal Cutting Blade: These blades are specifically designed for cutting various types of metal and often feature a finer tooth count. This design helps to minimize burrs and provides a smoother finish, making them a good choice for precision work and metal fabrication.

- Carbide-tipped Abrasive Blade: Abrasive blades are commonly used for cutting through hard metals and are composed of a metal core covered with an abrasive material. They create a lot of heat during cutting, which can lead to wear and tear but are effective for heavy-duty cuts on tough materials.

- Bi-metal Blade: Bi-metal blades combine two types of steel, providing flexibility and durability. They are effective for cutting a variety of metals and can withstand the high-stress conditions encountered when cutting thick or tough materials.

What Advantages Do Carbide-Tipped Blades Offer for Metal Cutting?

Carbide-tipped blades offer several advantages when it comes to cutting metal, making them an excellent choice for use on miter saws.

- Durability: Carbide-tipped blades are known for their exceptional durability, allowing them to withstand the rigors of cutting through tough materials like metal. The carbide tips are much harder than steel, which means they maintain their sharpness longer and can handle repeated use without becoming dull.

- Precision Cuts: These blades provide clean and precise cuts, which is essential when working with metal to ensure a proper fit and finish. The design of carbide-tipped blades minimizes chipping and deformation, resulting in smoother edges and reduced need for additional finishing work.

- Heat Resistance: Carbide-tipped blades can endure high temperatures generated during metal cutting, which helps prevent warping and damage to the blade. Their ability to resist heat allows for longer cutting sessions without a significant drop in performance, ensuring consistent results over time.

- Versatility: Carbide-tipped blades are versatile and can be used to cut a variety of metals, including aluminum, steel, and alloys. This makes them an ideal choice for various metalworking projects, whether you are a hobbyist or a professional.

- Reduced Friction: The design of carbide-tipped blades is optimized to reduce friction during cutting, which not only prolongs the life of the blade but also enhances the efficiency of the cutting process. This reduction in friction leads to less heat buildup, further protecting the blade and the material being cut.

How Does a Bi-Metal Blade Improve Cutting Performance?

A bi-metal blade enhances cutting performance by combining the durability of high-speed steel with the flexibility of carbon steel, making it ideal for cutting metal with a miter saw.

- Material Composition: Bi-metal blades are constructed from two different types of metals, typically high-speed steel (HSS) teeth welded to a flexible steel body. This combination allows the blade to maintain a sharp edge while being resistant to breakage and wear.

- Heat Resistance: The HSS teeth provide excellent heat resistance, allowing the blade to cut through metal without losing its temper or becoming dull quickly. This is particularly important when cutting harder materials that generate significant heat during the cutting process.

- Flexibility and Strength: The flexible steel body of the blade absorbs vibrations and reduces the risk of blade breakage during intense cutting tasks. This flexibility allows for smoother cuts and better handling of various metal thicknesses and types.

- Versatility: Bi-metal blades are suitable for a wide range of materials including aluminum, steel, and other metals, making them a versatile choice for various projects. This adaptability means that users can switch between different metal types without needing to change blades frequently.

- Tooth Design: The tooth design of bi-metal blades is often optimized for cutting metal, featuring a higher tooth count and specialized geometry for cleaner cuts. This design helps to reduce burr formation and provides a more precise finish, which is critical in metalworking applications.

When Should You Use a Diamond Blade on a Miter Saw?

Using a diamond blade on a miter saw is essential when cutting hard materials such as metal, tile, or concrete, as it provides a clean and precise cut.

- Material Type: Diamond blades are best suited for cutting hard materials like metal, ceramic tiles, or stone.

- Cutting Precision: They offer superior cutting precision compared to standard blades, making them ideal for intricate cuts and detailed work.

- Longevity: Diamond blades have a longer lifespan than traditional metal cutting blades, allowing for more extended use before needing replacement.

- Heat Resistance: These blades can handle the heat generated during cutting, reducing the risk of warping and ensuring consistent performance.

- Safety Considerations: Using diamond blades can enhance safety by reducing the risk of blade breakage and minimizing kickback when cutting tough materials.

Material Type: When working with harder materials like metal, the diamond blade is specifically designed to tackle the toughness without dulling quickly. Standard blades may struggle, leading to frayed edges or incomplete cuts.

Cutting Precision: The diamond segments on the blade ensure that the cutting edge remains sharp and effective, resulting in smoother and more accurate cuts. This precision is especially important for projects that require a high degree of accuracy.

Longevity: Diamond blades are not only effective for the task at hand but also last significantly longer than conventional blades, often providing several times the cutting capacity. This longevity makes them a cost-effective solution over time, despite a higher initial purchase price.

Heat Resistance: During metal cutting, friction can create substantial heat, which can damage both the blade and the material. Diamond blades are engineered to withstand this heat, ensuring that they maintain their integrity and effectiveness throughout the cutting process.

Safety Considerations: The robust construction of diamond blades minimizes the risk of breakage during operation, which can lead to accidents. Additionally, the reduced likelihood of kickback when cutting tough materials means safer operation for the user.

What Key Factors Affect the Choice of Metal Cutting Blade on a Miter Saw?

Several key factors influence the choice of a metal cutting blade for a miter saw:

- Material Type: The type of metal being cut is crucial in determining the appropriate blade.

- Teeth Design: The design and number of teeth on the blade affect the cutting speed and finish quality.

- Blade Thickness: The thickness of the blade can impact the durability and cutting performance.

- Coating: Blade coatings can enhance performance and longevity, especially when cutting harder materials.

- RPM Compatibility: Ensuring the blade is compatible with the miter saw’s RPM is essential for safe and effective cutting.

Material Type: Different metals such as aluminum, steel, or stainless steel require specific blade materials and designs. For instance, a blade designed for cutting aluminum may not perform well on steel due to the differences in hardness.

Teeth Design: Blades with fewer teeth are better for faster cuts, while blades with more teeth provide smoother finishes. Choosing the right teeth design will depend on the balance between speed and finish quality desired in the cut.

Blade Thickness: Thicker blades can withstand more stress and are less likely to bend or warp during cutting. However, thicker blades may also require more power from the miter saw, which can limit the types of saws they can be used with.

Coating: Blades with coatings such as carbide or titanium can significantly increase their lifespan and improve cutting performance. These coatings reduce friction and heat, making them ideal for high-volume or heavy-duty metal cutting tasks.

RPM Compatibility: Each blade is rated for a specific RPM range, and using a blade outside this range can lead to poor performance or even safety hazards. It’s essential to match the blade’s RPM rating with that of the miter saw to ensure safe operation and optimal cutting results.

How Does Tooth Count Impact the Blade’s Cutting Capability?

The tooth count of a blade significantly influences its cutting capability, especially when selecting the best blade to cut metal on a miter saw.

- Low Tooth Count (24-40 teeth): Blades with a lower tooth count are generally designed for faster, rougher cuts.

- Medium Tooth Count (40-60 teeth): These blades strike a balance between speed and finish, making them versatile for various metal cutting tasks.

- High Tooth Count (60+ teeth): Blades with a high tooth count are suited for producing smooth finishes and are ideal for precision cuts.

Low tooth count blades, typically ranging from 24 to 40 teeth, are effective for quick cuts in thicker metals. The fewer teeth allow for larger gullets, which helps in clearing chips and preventing the blade from binding during the cut.

Medium tooth count blades, usually between 40 and 60 teeth, offer a compromise between speed and finish quality. They are versatile enough to handle a range of materials while still providing a decent cut quality, making them a popular choice for general metalworking tasks.

High tooth count blades, often exceeding 60 teeth, are specifically designed for clean, fine cuts. These blades have smaller gullets, which reduces the amount of material removed with each pass, resulting in a smoother finish that is essential for detailed work or thinner materials.

Why is Blade Speed Critical When Cutting Different Metal Types?

Blade speed is critical when cutting different metal types because it directly influences the efficiency of the cut, the quality of the finish, and the lifespan of the blade. Higher blade speeds generate more heat, which can lead to material deformation, while lower speeds may result in dulling or inefficient cuts.

According to a study published in the Journal of Manufacturing Processes, different metals exhibit varying thermal conductivity and hardness levels, which significantly affect how they should be cut. For instance, softer metals like aluminum can be cut more effectively at higher speeds, while harder metals like stainless steel require lower speeds to prevent overheating and blade wear.

The underlying mechanism involves the interaction between the blade’s teeth and the metal’s material properties. When cutting softer metals, the blade can remove material quickly without much risk of damage, benefiting from higher speeds. Conversely, harder metals necessitate slower speeds to allow the cutting edges to penetrate effectively without causing excessive friction and heat. This balance is crucial for maintaining blade integrity, avoiding premature wear, and ensuring a clean cut.

Which Brands are Recognized for the Best Metal Cutting Blades?

The brands recognized for the best metal cutting blades for miter saws include:

- DeWalt: Known for durability and high performance, DeWalt’s metal cutting blades are designed with carbide tips that enhance cutting efficiency and extend the life of the blade. Their blades often feature a unique tooth design that allows for clean cuts in various types of metal, including aluminum and steel.

- Milwaukee: Milwaukee blades are engineered for optimal performance and longevity, utilizing advanced carbide formulations that withstand the rigors of cutting hard metals. Their metal cutting blades often have a specialized tooth geometry that minimizes burrs and ensures faster cutting speeds, making them ideal for professional applications.

- Makita: Makita is renowned for producing high-quality blades that provide smooth and precise cuts in metal materials. Their blades typically incorporate a heat-treated design that reduces wear and keeps the edges sharper for longer, allowing for more efficient cutting with less effort.

- Irwin: Irwin metal cutting blades are designed for versatility and can handle a variety of metal types effectively. They feature a unique tooth configuration that promotes faster cutting and reduced friction, making them suitable for both DIY projects and professional use.

- Bosch: Bosch offers a range of metal cutting blades that are known for their robust construction and effective cutting performance. Their blades often include features such as anti-vibration technology, which helps maintain stability during cuts, enhancing both precision and safety.

What Do User Reviews Indicate About Popular Brands?

User reviews provide valuable insights into the performance and reliability of tools like miter saws and their blades for cutting metal.

- Quality of the Blade: Many reviews highlight the importance of using high-quality blades, such as carbide-tipped options, for achieving clean cuts in metal. Users often report that a better quality blade not only lasts longer but also reduces the risk of chipping or warping during cutting.

- Compatibility with Miter Saws: It’s essential for users to ensure that the blade they choose is compatible with their specific miter saw model. Reviews frequently mention that certain blades work exceptionally well with specific brands, enhancing cutting efficiency and accuracy.

- Cutting Speed and Efficiency: User feedback often discusses how quickly and efficiently a blade can cut through different types of metal. Many reviewers appreciate blades that offer faster cutting speeds without sacrificing the quality of the finished cut, making projects less time-consuming.

- Durability and Lifespan: Reviews commonly address how long a blade lasts before dulling or needing replacement. Users typically favor blades that maintain their sharpness over extended periods, reducing the frequency of replacements and ensuring consistent performance throughout multiple projects.

- Noise and Vibration Levels: Some users comment on the noise and vibration produced while cutting with specific blades. Blades that reduce vibration are often preferred, as they provide a smoother cutting experience and less operator fatigue during prolonged use.

What Maintenance Practices Can Extend the Life of Your Metal Cutting Blade?

Implementing proper maintenance practices can significantly extend the life of your metal cutting blade.

- Regular Cleaning: Keeping your blade clean from dust, debris, and metal shavings is crucial for maintaining its cutting efficiency. Use a soft brush or compressed air to remove buildup, preventing rust and ensuring smooth cuts.

- Proper Lubrication: Applying a suitable lubricant can help reduce friction between the blade and the material being cut. This not only enhances the cutting performance but also minimizes wear and tear on the blade itself.

- Correct Storage: Storing your blade properly when not in use can prevent damage and corrosion. Use blade guards or dedicated storage cases to keep it protected from moisture and physical impacts.

- Periodic Inspection: Regularly inspect the blade for any signs of wear, such as chipped or broken teeth. Identifying and addressing issues early can prevent further damage and ensure optimal cutting performance.

- Using Appropriate Feed Rates: Adjusting the feed rate based on the material being cut can help maintain the integrity of the blade. Cutting too quickly can overheat the blade, while cutting too slowly may cause excessive wear, so finding the right balance is key.

- Sharpening When Necessary: Keeping the blade sharp is essential for effective cutting. Depending on usage, periodically sharpening the blade will restore its cutting edge and prolong its lifespan.

How Should You Clean Your Metal Cutting Blade to Maintain Its Performance?

To maintain the performance of a metal cutting blade on a miter saw, it’s essential to follow a proper cleaning routine that involves several steps:

- Regular Inspection: Frequently check the blade for any signs of wear or damage.

- Use Compressed Air: Blow off any metal shavings or debris accumulated on the blade.

- Soaking in Cleaning Solution: If the blade is heavily soiled, soak it in a specialized blade cleaning solution.

- Scrubbing with a Brush: Use a soft-bristle brush to gently scrub the blade after soaking.

- Drying and Lubrication: Thoroughly dry the blade and apply a light lubricant to prevent rust.

Regular Inspection: Inspecting the blade regularly helps identify wear, dull edges, or any chips that may affect cutting performance. A well-maintained blade not only cuts better but also lasts longer, ensuring efficiency in your projects.

Use Compressed Air: Using compressed air is an effective way to remove metal shavings and dust that can accumulate on the blade during use. This quick action prevents buildup, which can lead to overheating and decreased cutting performance.

Soaking in Cleaning Solution: For blades with heavy residue, soaking in a specialized cleaning solution can dissolve built-up grime and debris. Make sure to follow the manufacturer’s recommendations for the best cleaning solutions suitable for metal cutting blades.

Scrubbing with a Brush: After soaking, use a soft-bristle brush to gently scrub the blade, focusing on the teeth where debris tends to accumulate. Avoid using abrasive materials that could damage the blade or alter its cutting edge.

Drying and Lubrication: Once cleaned, thoroughly dry the blade with a lint-free cloth to prevent moisture from causing rust. Additionally, applying a light lubricant can protect the blade from corrosion and ensure smoother operation during future cuts.

When is it Time to Replace Your Blade for Optimal Performance?

Knowing when to replace your blade is crucial for maintaining optimal performance when cutting metal with a miter saw.

- Visible Damage: If you notice any chips, cracks, or missing teeth on the blade, it’s time to replace it.

- Excessive Heat: If the blade becomes excessively hot during use, this may indicate dullness or damage, necessitating a replacement.

- Increased Resistance: If you experience more resistance while cutting, it can signal that the blade is no longer effective and should be changed.

- Poor Cut Quality: If your cuts are rough or inconsistent, it may mean the blade is dull and needs to be replaced for better precision.

- Frequent Binding: If the blade frequently binds in the material during cuts, this can indicate wear and a need for a new blade.

Visible damage to the blade is a clear sign that it needs replacing, as any chips, cracks, or missing teeth can affect the cutting performance and safety. A blade with physical damage poses risks not only to the workpiece but also to the user, making timely replacement essential.

Excessive heat during cutting indicates that the blade is struggling to perform effectively, often due to dullness or damage. If the blade heats up significantly, it can lead to warping or further deterioration, highlighting the importance of using a sharp and intact blade.

Increased resistance when making cuts is another indicator that the blade may be worn out. If you find yourself applying more pressure than usual, it’s a good idea to check the condition of the blade and consider replacing it to ensure a smoother cutting experience.

Poor cut quality, characterized by rough edges or inconsistent finishes, often points to a dull blade that can no longer make clean cuts. A fresh blade will restore the precision and quality of your work, making it vital to replace it when you notice these issues.

Frequent binding of the blade during cuts can be a sign of wear, indicating that the blade is not cutting efficiently. This can lead to frustrating interruptions in your work and can also pose safety risks, making it an important factor in deciding when to replace your cutting blade.

What Essential Safety Tips Should Be Followed When Using a Miter Saw with Metal Cutting Blades?

When using a miter saw with metal cutting blades, it’s crucial to follow essential safety tips to ensure effective cutting and personal safety.

- Wear Personal Protective Equipment (PPE): Always wear safety glasses and hearing protection when operating a miter saw.

- Secure Your Workpiece: Ensure that the material being cut is securely clamped or held in place to prevent movement during cutting.

- Check Blade Compatibility: Use blades specifically designed for metal cutting to ensure efficiency and safety.

- Adjust Cutting Speed: Set the miter saw to the appropriate speed for cutting metal, as this can greatly affect performance and blade life.

- Avoid Overheating: Monitor the blade temperature and allow it to cool if it becomes too hot during use.

- Keep Work Area Clean: Maintain a clean workspace to avoid tripping hazards and ensure that metal shavings are promptly cleaned up.

- Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for both the saw and the blade to ensure safe operation.

Wearing personal protective equipment like safety glasses and hearing protection is essential to shield yourself from flying debris and excessive noise while cutting metal.

Securing your workpiece is critical to prevent any movement that could lead to inaccurate cuts or accidental injury; using clamps or a vice can greatly enhance stability.

Blade compatibility is vital; using blades specifically designed for metal ensures that you get the best cutting performance and reduces the risk of blade damage or breakage.

Adjusting the cutting speed appropriately is important as different types of metal may require different speeds for optimal cutting without compromising the blade’s integrity.

Avoiding overheating is equally important, as excessive heat can dull the blade quickly, and in some cases, lead to blade failure; if the blade feels hot, take a break to allow it to cool down.

Keeping your work area clean helps to prevent accidents and makes it easier to manage metal shavings, which can pose a slipping hazard and interfere with your cutting precision.

Lastly, following the manufacturer’s guidelines will provide you with specific safety and operational advice, ensuring that you use your miter saw and metal cutting blade effectively and safely.

Related Post: