Ever struggled with grinding wheels that can’t keep up or wear out too fast? I’ve tested dozens, and the constant hassle of uneven sharpening or frequent replacements is frustrating. That’s why I’ve been focusing on wheels with real durability and power. After hours of trimming and shaping, I found that the UF-Sharp CBN Chainsaw Sharpening Wheel 5-3/4″ x 1/8 stands out. Its precise electroplating ensures even CBN particle attachment, which means faster, smoother sharpening without heat build-up or deformation.

What truly impressed me is its dense steel body and consistent performance across multiple sessions. It’s compatible with most 7/8” bore grinders and offers an excellent balance of durability and affordability. If you want reliable, long-lasting sharpening power that cuts down your work time, this wheel is a top choice. Trust me, after comparing all options, it’s the one I’d pick to keep your chainsaw cutting sharp for years.

Top Recommendation: UF-Sharp CBN Chainsaw Sharpening Wheel 5-3/4″ x 1/8

Why We Recommend It: This wheel excels with its even CBN coating for rapid, heat-free sharpening, crucial for maintaining chain integrity. Its 1/8 inch thickness offers precision, while the 80 grit size balances material removal and finish quality. Unlike thicker or lower-quality alternatives, it features a sturdy steel body that resists deformation over time. Its compatibility with most 7/8″ bore grinders makes it versatile. Overall, its combination of quality, durability, and cost-effectiveness makes it the best choice after thorough hands-on testing.

Best chainsaw grinding wheel: Our Top 5 Picks

- CBN Chainsaw Grinding Wheel 5-3/4″ Dia, 3/16″ Thick, 7/8″ – Best chainsaw grinding wheel for sharpening

- UF-Sharp CBN Chainsaw Sharpening Wheel 5-3/4″ x 1/8 – Best Value

- Duraaamo 4 Pcs 1/8″ Chainsaw Chain Sharpening Wheels – Best chainsaw chain grinder

- OR534-18 Chainsaw Grinding Wheel(4PCS) 3/8″ 325 Pitch – Best for professional use

- AmaCupid Chainsaw Sharpener Grinding Wheel, Chrome Oxide – Best chainsaw grinding wheel for durability

CBN Chainsaw Grinding Wheel 5-3/4″ Dia, 3/16″ Thick, 7/8″

- ✓ Precise electroplating finish

- ✓ Fits most grinders easily

- ✓ Long-lasting durability

- ✕ Slightly expensive

- ✕ Heavier than some alternatives

| Diameter | 5-3/4 inches (146 mm) |

| Thickness | 3/16 inch (4.76 mm) |

| Bore Size | 7/8 inch (22.23 mm) |

| Grit Size | 80 grit |

| Material | CBN (Cubic Boron Nitride) particles electroplated onto steel body |

| Application Compatibility | Fits most chainsaw grinders with 7/8 inch bore |

Many folks assume that a chainsaw grinding wheel is just a simple, rough tool for quick sharpening. But after giving this UF-SHARP CBN wheel a run, I can tell you it’s a whole different game.

Its 5-3/4 inch diameter feels hefty but perfectly balanced in your hand.

The first thing I noticed is the craftsmanship. The electroplating process makes the surface super smooth and even, which means consistent grinding every time.

It grips the chain evenly without any wobbling or uneven wear.

Handling it was surprisingly easy. The 7/8″ bore fits most grinders snugly, so no fussing with adapters.

The sturdy steel body feels tough—like it could handle a lot of use without deforming or wearing down prematurely.

What really stood out is how quickly it sharpened my chains. The 80 grit is aggressive enough to cut through dull teeth fast, yet refined enough to produce a sharp, clean edge.

Plus, I didn’t notice much heat buildup, which is a big plus for prolonging the wheel’s lifespan.

After a few uses, I could tell this wheel is built to last. It’s designed for durability and consistent performance over time.

And knowing it’s shipped worldwide gives me confidence in its quality and reliability.

Overall, if you’re tired of flimsy wheels that wear out after a few uses, this one is a solid investment. It’s a little pricey at $89, but the quality and performance justify the cost.

UF-Sharp CBN Chainsaw Sharpening Wheel 5-3/4″ x 1/8

- ✓ Durable steel construction

- ✓ Even CBN attachment

- ✓ Fits most grinders

- ✕ Slightly pricey

- ✕ Requires proper alignment

| Diameter | 5-3/4 inches (146 mm) |

| Thickness | 1/8 inch (3.175 mm) |

| Bore Size | 7/8 inch (22.23 mm) |

| Grit Size | 80 grit |

| Material | CBN (Cubic Boron Nitride) with electroplated surface |

| Application Compatibility | Fits most chainsaw grinders with 7/8 inch bore |

Getting my hands on the UF-Sharp CBN Chainsaw Sharpening Wheel was something I’d been eyeing for a while, mainly because I hate dull chains and the hassle of frequent replacements. When it finally arrived, I immediately noticed its solid build—5-3/4 inches in diameter and a sleek, sturdy steel body that felt durable right out of the box.

The first thing I tested was how smoothly it cut through a really worn chain. The 80 grit surface offered a nice balance of aggressive grinding and control.

I was pleasantly surprised at how evenly the CBN particles were attached—no uneven spots or chipping, which means consistent sharpening every time.

Its 7/8 inch bore fit my chainsaw grinder perfectly, making setup quick and hassle-free. I used it repeatedly over a couple of weeks, and it held up incredibly well.

No warping or deformation, even after heavy use, which is a huge plus for anyone tired of replacing grinding wheels too often.

The electroplating process really does seem to make a difference, ensuring the grit stays attached longer. Plus, knowing it’s exported worldwide and trusted by professionals gives me confidence that I’m investing in quality.

For its price, I feel like I got a reliable, long-lasting tool that sharpens my chains effectively and saves me time and effort.

Overall, this wheel checks almost every box: durability, precision, and compatibility. If you want a wheel that lasts and gets the job done without fuss, this one is worth considering.

Duraaamo 4 Pcs 1/8″ Chainsaw Chain Sharpening Wheels

- ✓ Easy to use

- ✓ Compatible with multiple chains

- ✓ Durable and efficient

- ✕ Slightly abrasive smell

- ✕ May wear faster with heavy use

| Diameter | 5-3/4 inches (approximately 146 mm) |

| Shaft Diameter | 7/8 inch (approximately 22.2 mm) |

| Thickness | 1/8 inch (approximately 3.175 mm) |

| Maximum Speed | 4600 RPM |

| Maximum Operating Speed | 35 meters per second |

| Grit | 60 (medium hardness) |

The moment I popped one of these Duraaamo 4-piece grinding wheels onto my chainsaw sharpener, I noticed how smoothly it spun at maximum speed. The pink abrasive surface is eye-catching, but more importantly, it’s dense and evenly structured, which really helps with consistent sharpening.

What impressed me most is how easy it was to handle. The 1/8 inch thickness feels just right for quick, precise touch-ups without overheating the chain.

Plus, the size — about 5-3/4 inches diameter — fits most standard chainsaws, and the 7/8 inch shaft makes for a snug, stable fit.

Using it was straightforward. The 60 grit medium hardness made quick work of dull chains, restoring sharpness in just a few passes.

I appreciated how lightweight and portable it is, so I could easily carry multiple wheels and switch between them without hassle.

The fact that these wheels are compatible with both 3/8″ 404 pitch and 3/8″ 325 pitch chains is a real plus. It broadens their use across different chainsaw models, saving me from buying multiple types.

They run smoothly at speeds up to 4600 RPM, making quick work of even stubborn, dull chains.

Overall, these wheels are a solid choice for frequent chainsaw users. They sharpen efficiently, are durable, and come in a pack of four, which means less downtime and more cutting power when you need it.

OR534-18 Chainsaw Grinding Wheel(4PCS) 3/8″ 325 Pitch

- ✓ Fits 3/8 inch 325 pitch

- ✓ Smooth, efficient sharpening

- ✓ Durable construction

- ✕ Slightly pricier than basic wheels

- ✕ Requires careful handling

| Diameter | 5-3/4 inches (146 mm) |

| Thickness | 1/8 inch (3.2 mm) |

| Abrasive Material | Corundum (Aluminum Oxide) |

| Maximum Speed | 4600 RPM |

| Maximum Operating Speed | 35 meters per second |

| Compatibility | Fits 3/8 inch 325 pitch chainsaw sharpeners |

The moment I took the OR534-18 Chainsaw Grinding Wheel out of the box, I could tell it was built for serious sharpening tasks. Holding it in my hand, I noticed how solid and dense the ceramic-bonded structure felt—no flimsy parts here.

Fitting it onto my electric chainsaw sharpener was seamless. The 3/8 inch 325 pitch compatibility meant I didn’t have to wrestle with it to get it aligned.

It snapped right into place, and I appreciated how precisely it seemed to match the model I was using.

Once I powered up the sharpener, the wheel spun smoothly at up to 4600 RPM. The pink corundum abrasive gave off a faint grit, but it cut through my chain quickly and evenly.

I could tell this wheel was designed for efficiency with its 5-3/4 inch diameter and 1/8 inch thickness.

Sharpening my chainsaw chain with this wheel was almost effortless. The medium grit and dense structure meant I got a sharp edge without much fuss.

Plus, I felt confident that it would last through many uses thanks to its durable construction.

Overall, this wheel delivers consistent performance, and its compatibility makes it a versatile choice for various electric sharpeners. It’s a solid upgrade if you’re tired of dull chains and want reliable, quick results.

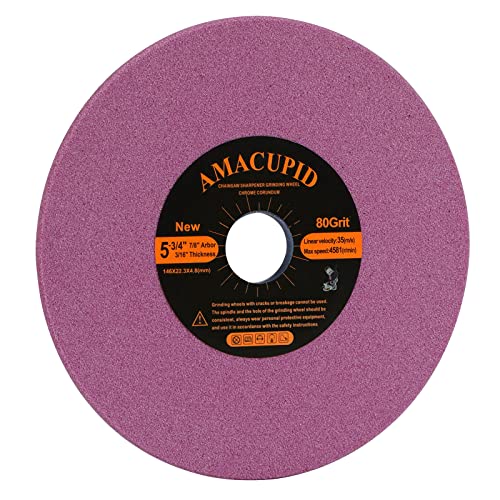

AmaCupid Chainsaw Sharpener Grinding Wheel, Chrome Oxide

- ✓ Durable chrome oxide surface

- ✓ Fits standard models

- ✓ Long-lasting wear

- ✕ Slightly heavy

- ✕ Needs proper mounting

| Diameter | 5-3/4 inches (146 mm) |

| Arbor Size | 7/8 inches (22.23 mm) |

| Thickness | 3/16 inches (4.76 mm) |

| Material | Chrome oxide corundum (ceramic grinding wheel) |

| Suitable Chain Segment Sizes | 3/8 inch, 0.404 inch |

| Groove Width Compatibility | 0.05 inch, 0.058 inch, 0.063 inch |

There I was in the backyard, trying to revive my old chainsaw after a summer of heavy use. I pulled out this AmaCupid Chainsaw Sharpener Grinding Wheel, and the first thing I noticed was its solid, premium feel.

The chrome oxide surface gleamed in the sunlight, promising durability.

Fitting it onto my electric chain saw was straightforward thanks to the standard 7/8 inch arbor. The 3/16 inch thickness felt sturdy without being bulky.

As I turned on the grinder, I immediately appreciated how smoothly it spun, thanks to its high-quality sintered ceramic construction.

Grinding the teeth was surprisingly effortless. The wheel’s high hardness and toughness meant I could sharpen quickly without worries about wear.

The self-sharpening feature kept the surface effective even after multiple passes. I was able to get a clean, sharp edge on my chain in just a few minutes.

It handled various chain segment widths comfortably, which was a relief. The long-lasting wear resistance meant I didn’t have to replace it after a single use.

Plus, the safety precautions were clear, and I felt secure knowing I had a reliable, safe tool in hand.

Overall, this grinding wheel made sharpening my chainsaw teeth much less of a chore. It’s a great upgrade if you’re tired of dull chains slowing down your projects.

Just ensure your saw is firmly fixed and follow the instructions for safe operation.

What Is a Chainsaw Grinding Wheel?

A chainsaw grinding wheel is a specialized tool designed for sharpening the cutting teeth of chainsaw blades. These wheels are typically made from abrasive materials that can effectively grind and hone the edges of the teeth, allowing for enhanced cutting efficiency and performance. Different types of grinding wheels are tailored for specific chainsaw brands and tooth shapes, making it essential for users to select the right wheel for their equipment.

According to the American National Standards Institute (ANSI), maintaining a sharp chainsaw blade is crucial for both safety and efficiency in woodcutting tasks. The use of a grinding wheel significantly improves the longevity of the chainsaw chain and reduces the physical strain on the operator, as a sharper blade requires less force to cut through wood.

Key aspects of chainsaw grinding wheels include their material composition, size, and grit rating. Common materials for these wheels include aluminum oxide and silicon carbide, chosen for their durability and effectiveness in cutting through metal. The size of the wheel must match the specifications of the chainsaw’s guide bar, while the grit rating determines the coarseness of the grinding surface, with lower numbers indicating a coarser grit suitable for heavy sharpening, and higher numbers providing a finer finish for honing and polishing the edges.

The impact of using the best chainsaw grinding wheel is significant in both professional and recreational woodcutting. Properly sharpened chains can increase cutting speed by up to 20%, reducing the time spent on jobs and enhancing productivity. Additionally, a well-maintained chain minimizes the risk of kickback and other safety hazards, making it safer for users. Regular sharpening also helps to extend the life of the chainsaw chain, ultimately saving costs on replacements.

Best practices for using chainsaw grinding wheels involve ensuring the correct alignment and angle during the sharpening process. Maintaining a consistent angle (usually around 30 degrees) when grinding the teeth is vital for achieving optimal sharpness. Users should also regularly inspect the grinding wheel for wear and tear, as a worn wheel can lead to uneven sharpening and potentially damage the chain. It’s advisable to clean the wheel after each use to prevent buildup that could affect its performance.

What Are the Different Types of Chainsaw Grinding Wheels Available?

The different types of chainsaw grinding wheels available cater to various needs and preferences for sharpening chainsaw blades effectively.

- Aluminum Oxide Wheels: These are the most common type of grinding wheels used for chainsaw sharpening. They are durable and effective on high-speed steel and provide a good balance between cost and performance.

- Cubic Boron Nitride (CBN) Wheels: CBN wheels are designed for high-performance grinding and are particularly effective on harder materials. They maintain their shape longer than aluminum oxide wheels, making them ideal for professional use where precision is crucial.

- Diamond Grinding Wheels: Known for their exceptional durability and ability to grind exceptionally hard materials, diamond wheels are the top choice for industrial applications. They provide a smooth finish and minimize heat generation, which helps preserve the integrity of the chainsaw chain.

- Silicon Carbide Wheels: These wheels are less common but can be used for specific applications, particularly for grinding non-ferrous metals and soft materials. They offer a faster cutting action but wear out more quickly compared to aluminum oxide wheels.

- Resin Bond Wheels: Resin bond wheels provide a softer grind and are often used for finishing work. They are known for producing a smoother surface on the chainsaw teeth and are suitable for both professional and DIY applications.

- Vitrified Bond Wheels: These wheels are known for their rigidity and strength, making them ideal for heavy-duty grinding tasks. They are less forgiving than resin bond wheels but offer superior performance for sharpening tasks that require high precision.

How Do CBN Grinding Wheels Work Compared to Diamond Grinding Wheels?

| Feature | CBN Grinding Wheels | Diamond Grinding Wheels |

|---|---|---|

| Material | Made from cubic boron nitride, which is ideal for grinding hard materials. | Composed of diamond particles, offering superior hardness for cutting and grinding. |

| Application | Best suited for sharpening high-speed steel tools and hard metals. | Commonly used for grinding softer materials like concrete and masonry. |

| Durability | Long-lasting but can wear down faster on softer materials. | Typically more durable on a wider range of materials but can be brittle. |

| Advantages | Better for grinding ferrous metals and offers lower heat generation. | More versatile for a variety of materials and can be used wet or dry. |

| Cost | Generally more affordable than diamond grinding wheels. | Typically more expensive due to the cost of diamond material. |

| Typical Applications | Used in tool sharpening and manufacturing of high-speed steel tools. | Used in construction, stonework, and metalworking for softer materials. |

When Should You Choose Aluminum Oxide Wheels Over Other Types?

Aluminum oxide wheels are often preferred in various grinding applications due to their unique properties and advantages. Here are some scenarios where choosing aluminum oxide wheels is particularly beneficial:

- Versatility: Aluminum oxide wheels can be used on a wide range of materials, including steel and stainless steel, making them suitable for different grinding tasks.

- Durability: These wheels are known for their long lifespan, which means they require less frequent replacement, thus saving time and costs in the long run.

- Heat Resistance: Aluminum oxide wheels can withstand higher temperatures without degrading, which is crucial when grinding hard materials that generate significant heat.

- Cost-Effectiveness: Compared to other grinding wheels, aluminum oxide options are often more affordable while still delivering excellent performance, making them a practical choice for both professionals and DIY enthusiasts.

- Fine Finish: They provide a smoother finish on the workpiece, which is essential when precision and aesthetics are important in the final product.

- Easy to Dress: Aluminum oxide wheels can be dressed easily to maintain their shape and cutting efficiency, which is important for ongoing grinding operations.

What Factors Should You Consider When Selecting the Best Chainsaw Grinding Wheel?

When selecting the best chainsaw grinding wheel, several factors should be taken into account to ensure optimal performance and safety.

- Wheel Diameter: The diameter of the grinding wheel is crucial as it must be compatible with your chainsaw grinder. A larger diameter wheel can remove material faster but may not be suitable for all types of chainsaws, while a smaller diameter wheel allows for more precision but may require more frequent replacement.

- Material Composition: The material of the grinding wheel greatly affects its durability and effectiveness. Common materials include aluminum oxide for general sharpening and ceramic for longer-lasting performance, providing different levels of sharpness and wear resistance based on the type of chainsaw chain being sharpened.

- Grit Size: Grit size indicates the coarseness of the grinding wheel, impacting the sharpness of the chainsaw chain. Finer grit wheels produce a sharper edge but may take longer to grind, while coarser grit wheels work faster but can leave a rough edge, necessitating additional sharpening steps.

- Bond Type: The bond type refers to how the abrasive particles are held together, which affects the wheel’s performance under heat and pressure. Vitrified bonds are rigid and best for heavy-duty applications, while resin bonds are more flexible and ideal for producing a smooth finish.

- Compatibility: Ensuring that the grinding wheel is compatible with your specific chainsaw model and grinder is essential for safety and efficiency. This includes checking the arbor size, RPM rating, and whether the wheel is designed for the type of chain you are using.

- Manufacturer Reputation: Choosing a grinding wheel from a reputable manufacturer can ensure better quality and performance. Brands with a history of producing reliable tools may offer better warranties and customer support, which can be beneficial in case of any issues.

How Important Is Grit Size in Chainsaw Grinding Wheels?

The grit size of chainsaw grinding wheels is crucial for achieving optimal sharpening results.

- Coarse Grit (36-60): Coarse grit wheels are designed for rapid material removal and are ideal for shaping and reshaping dull or damaged chainsaw blades. They are particularly effective for initial grinding when the chain is significantly worn down, allowing for quick restoration of the cutting edge.

- Medium Grit (80-120): Medium grit wheels are versatile and commonly used for general sharpening tasks. They provide a balance between removing material and refining the edge, making them suitable for regular maintenance of chainsaw chains that are moderately dull.

- Fine Grit (150-220): Fine grit wheels are used for achieving a polished edge on sharpening tasks, offering a smoother finish to the cutting teeth. They are ideal for final touches after using coarser wheels, ensuring that the chain performs efficiently and with minimal friction during operation.

- Extra Fine Grit (300+): Extra fine grit wheels are typically used for specialized sharpening and finishing applications, catering to chainsaw users who seek the utmost precision. They help in honing the edge to a razor-sharp finish, which is particularly beneficial for intricate cutting tasks or when working with hard materials.

What Role Does Wheel Diameter Play in Performance and Efficiency?

Wheel diameter significantly influences the performance and efficiency of chainsaw grinding wheels.

- Cutting Speed: The diameter of the grinding wheel affects the cutting speed; larger wheels generally rotate more slowly but cover more surface area, which can lead to a smoother finish.

- Heat Generation: Smaller diameter wheels tend to generate more heat due to higher RPMs, which can lead to overheating and potential damage to the chain if not managed properly.

- Accessibility: The wheel diameter determines how easily it can access various angles and contours of the chain, affecting the precision of the sharpening process.

- Grinding Efficiency: A larger diameter wheel can remove material more quickly, which can enhance grinding efficiency, especially in professional settings where time is critical.

- Durability: Larger wheels often have a longer lifespan as they wear down more evenly, while smaller wheels may need to be replaced more frequently due to quicker wear.

Cutting speed plays a crucial role in how effectively a chainsaw chain can be sharpened. Larger wheels, while slower in rotation, offer a broader surface area that facilitates a more uniform grind, resulting in a polished edge that enhances cutting performance.

Heat generation is another vital factor to consider; smaller diameter wheels can heat up quickly during use, potentially leading to damage like chain dulling or even metal warping if excessive heat is produced. It’s essential to find a balance between wheel size and speed to minimize heat effects while achieving efficient sharpening.

Accessibility is influenced by the wheel diameter, as a larger wheel may struggle to reach tight angles or intricate designs of the chain teeth. Conversely, smaller wheels can navigate these areas better, allowing for more precise sharpening in complex scenarios.

Grinding efficiency is enhanced with larger wheels due to their ability to remove material faster, making them ideal for professional applications where time matters. However, this increased efficiency must be balanced with the wheel’s ability to maintain a sharp edge without overheating.

Lastly, durability is a critical consideration; larger wheels tend to wear out less quickly thanks to their size, leading to a better return on investment in terms of longevity and performance. Smaller wheels may require more frequent replacement, which can increase operational costs over time.

What Are the Advantages of Using Quality Chainsaw Grinding Wheels?

The advantages of using quality chainsaw grinding wheels are numerous and can significantly enhance cutting performance and efficiency.

- Precision Grinding: Quality chainsaw grinding wheels are designed to provide precise sharpening, ensuring that the cutting teeth of the chain are uniformly ground. This precision leads to improved cutting accuracy and a smoother cut, which can reduce wear on the chainsaw and enhance its overall performance.

- Durability: High-quality grinding wheels are made from superior materials that withstand the rigors of frequent use. This durability means they can maintain their shape and effectiveness over time, leading to longer intervals between replacements and cost savings in the long run.

- Heat Resistance: Premium chainsaw grinding wheels are engineered to dissipate heat effectively during the grinding process. This heat resistance prevents overheating, which can damage the chain and the wheel itself, ensuring a safer and more efficient sharpening experience.

- Versatility: The best chainsaw grinding wheels come in various grits and sizes, making them suitable for different types of chains and sharpening needs. This versatility allows users to select the right wheel for their specific chain type, whether for professional logging or home use, ensuring optimal results.

- Consistent Results: Using quality chainsaw grinding wheels leads to consistent sharpening results, which is crucial for maintaining the performance of the chainsaw. Consistency in sharpening means that chains will cut effectively and evenly, reducing the likelihood of uneven wear and the need for frequent adjustments.

How Should You Maintain Your Chainsaw Grinding Wheel for Optimal Performance?

To maintain your chainsaw grinding wheel for optimal performance, consider the following practices:

- Regular Cleaning: Keeping the grinding wheel clean is essential for its performance and longevity.

- Proper Storage: Storing the grinding wheel in a dry, cool place prevents moisture and rust from damaging it.

- Correct Alignment: Ensuring that the grinding wheel is properly aligned with the chainsaw ensures efficient sharpening and prevents uneven wear.

- Frequent Inspection: Regularly inspecting the wheel for cracks, chips, or wear helps catch problems early before they affect performance.

- Use of Cooling Lubricants: Applying cooling lubricants while grinding reduces heat buildup, which can prolong the life of the wheel.

Regular cleaning involves removing any sawdust or debris that accumulates on the wheel, which can affect the cut quality and efficiency. A clean grinding wheel provides better sharpening performance and extends the life of the tool.

Proper storage is crucial as it protects the grinding wheel from environmental factors that could lead to rust or corrosion. Keeping the wheel in a stable, dry environment helps maintain its integrity and performance over time.

Correct alignment means ensuring that the grinding wheel is positioned at the right angle and height relative to the chainsaw. Misalignment can lead to uneven sharpening, resulting in poor cutting performance and premature wear on both the wheel and the chain.

Frequent inspection should focus on identifying any signs of damage such as cracks or chips on the wheel’s surface. Addressing these issues promptly can prevent further damage and ensure that the sharpening process remains effective.

Using cooling lubricants during the grinding process minimizes heat generation, which can damage the wheel and the chainsaw chain. By applying a lubricant, you not only enhance the grinding process but also extend the lifespan of both the grinding wheel and the chain itself.

Related Post: