Contrary to what manufacturers claim about metal cutting blades, my hands-on testing revealed that it’s all about tooth durability and heat management. I chipped away with several blades, and the FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor stood out. Its high-density carbide teeth handled aluminum, brass, and copper smoothly, giving clean, burr-free cuts even in tough materials.

This blade’s TCG geometry and triple chip grind design provide remarkable lifespan and cut accuracy. It minimizes clogging and heat build-up, which keeps the blade sharp longer and the cut precise. Other blades like the Echo Corner 10″ or IVY Classic 10″ offered decent performance but lacked the same durability and clean finish when pushing through thicker or more resistant metals. The TOMAX 12-inch came close but was less robust in impact resistance and didn’t match the FOXBC’s long-term performance.

If you’re after a reliable, long-lasting blade that guarantees clean cuts and handles a range of non-ferrous metals with ease, the FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor is your best bet. Trust me—it’s the blade that really delivers in real-world use!

Top Recommendation: FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

Why We Recommend It: This blade excels because of its high-density carbide construction, which withstands impact and reduces wear. Its triple chip grind (TCG) teeth ensure sharp, burr-free cuts and longer lifespan, outperforming less specialized blades like the Echo Corner or IVY Classic. The design also effectively reduces clogging and heat buildup, key for smooth, precise cuts on aluminum and other non-ferrous metals.

Best metal cutting blade for miter saw: Our Top 5 Picks

- FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor – Best for Miter and Chop Saws

- Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T – Best for Miter and Chop Saws

- TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade, 1-Inch Arbor – Best for Miter and Chop Saws

- IVY Classic 40088 Swift Cut 10-Inch x 3/32-Inch x 5/8-Inch – Best for Circular Saws

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

- ✓ Clean, burr-free cuts

- ✓ Long-lasting carbide build

- ✓ Smooth, quiet operation

- ✕ Not ideal for very thick metals

- ✕ Slightly pricey

| Blade Diameter | 12 inches (305 mm) |

| Tooth Count | 120 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Width | .095 inches (2.41 mm) |

| Cutting Capacity | Suitable for aluminum extrusions up to 1/8 inch, 3/32 to 1/4 inch, and 3/16 to 7/16 inch thick metals |

This FOXBC 12″ aluminum cutting blade has been sitting on my wishlist for a while, mainly because I needed a reliable blade for cutting aluminum extrusions and copper pipes without fuss. When I finally got my hands on it, I was eager to see if it could handle the daily grind and deliver those clean, burr-free cuts it promises.

The first thing I noticed is how solid this blade feels. The 12-inch diameter is perfect for my miter saw, and the 120 teeth give it a really smooth action.

The carbide construction feels premium, and it’s tough enough to withstand impact without chipping. I used it on a mix of medium and thick aluminum pieces, and it cut through effortlessly.

What really impressed me is the triple chip grind (TCG) tooth design. It delivers fast, clean cuts without clogging or burrs, which is a huge time-saver.

The kerf of .095 inches means minimal material waste, and the hook angle of -5° helps with smoother slicing. I also appreciated how quiet and stable it felt during operation, even on thicker materials.

Overall, it stayed sharp longer than I expected, and I didn’t notice any overheating or dulling after multiple cuts. The price is fair for the quality, making it a solid choice for anyone working with non-ferrous metals regularly.

Just keep in mind, it’s best suited for thin to medium thickness metals—very thick pieces might still need a heavier-duty blade.

Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T

- ✓ Smooth, clean cuts

- ✓ Quiet operation

- ✓ Long-lasting durability

- ✕ Slightly pricy

- ✕ Limited to metal cutting

| Diameter | 10 inches (254 mm) |

| Tooth Count | 52 teeth |

| Blade Material | Cermet Carbide with TCG (Triple Chip Grind) |

| Kerf Thickness | 0.079 inches (2.01 mm) |

| Max RPM | 4000 RPM |

| Arbor Size | 1 inch (25.4 mm) with 5/8-inch reducing ring |

The Echo Corner 10″ Metal Cutting Miter/Table Saw Blade 52T immediately caught my attention with its solid build and promising features. It’s designed to handle a variety of materials like mild steel, aluminum, and even ferrous and non-ferrous sheets or tubes, making it versatile for different projects.

What really stood out during testing was its triple chip grind (TCG) design with 52 teeth, which delivered clean, fast cuts without much fuss, even through thicker materials. The laser-cut stabilizer vents helped keep the blade cool and reduce vibration, resulting in less noise and a smoother cut, especially when working with non-ferrous sheet or plate metals. When comparing different best metal cutting blade for miter saw options, this model stands out for its quality.

Overall, the Echo Corner blade impressed me with its ability to cut efficiently at up to 4000 RPM, maintaining accuracy and durability over multiple uses. If you’re after a reliable, long-lasting metal cutting blade that adapts to different center shafts using its 1-inch arbor and 5/8-inch reducing ring, this is a solid choice for your miter saw setup.

TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade, 1-Inch Arbor

- ✓ Long-lasting carbide teeth

- ✓ Smooth, clean cuts

- ✓ Rust-resistant coating

- ✕ Less effective on ferrous metals

- ✕ Slightly pricey for occasional use

| Blade Diameter | 12 inches (305 mm) |

| Tooth Count | 100 teeth |

| Arbor Size | 1 inch (25.4 mm) |

| Cutting Material Compatibility | Plastic, Aluminum, Non-Ferrous Metals |

| Tooth Material | Construction grade carbide |

| Coating | Electrophoretic coating for rust and corrosion resistance |

Many folks assume that all metal cutting blades are pretty much the same, just with different sizes or brands. I used the TOMAX 12-Inch 100-Tooth TCG Metal Saw Blade, and I can tell you, it’s a whole different ball game when it comes to cutting non-ferrous metals and plastics.

Right out of the box, you notice its solid build. The construction grade carbide teeth feel sturdy, and the electrophoretic coating gives it a sleek, rust-resistant finish.

It’s lightweight enough to handle easily, but heavy-duty enough to inspire confidence during use.

The blade’s teeth are designed with a TCG grind, which really shows when you’re making smooth, clean cuts. I tested it on aluminum and some plastic piping, and the results were impressive—fewer burrs, less fuss.

It also cut through thicker pieces without bogging down or overheating.

You’ll appreciate how long-lasting this blade seems. The manufacturer’s limited lifetime warranty says a lot about its durability, and I can confirm it holds up well after multiple cuts.

Plus, the price of around $30 feels fair for the quality and performance you’re getting.

Operation is smooth—minimal vibration, quiet cutting, and a clean finish that saves you time on cleanup. It’s a great upgrade if your current blade is struggling with non-ferrous metals or plastic.

Just keep in mind that it’s optimized for these materials; it might not be the best choice for thicker steel or ferrous metals.

IVY Classic 40088 Swift Cut 10-Inch x 3/32-Inch x 5/8-Inch

- ✓ Fast and clean cuts

- ✓ Durable fiberglass reinforcement

- ✓ Good value for money

- ✕ Not for high-speed saws

- ✕ Limited to ferrous metals

| Diameter | 10 inches |

| Thickness | 3/32 inch |

| Arbor Size | 5/8 inch |

| Maximum RPM | 6,100 RPM |

| Blade Type | Type 1 (cutting only) |

| Material and Construction | Resin bonded Aluminum-Oxide grain with fiberglass mesh reinforcement |

The moment I grabbed the IVY Classic 40088 Swift Cut blade, I immediately noticed its sturdy build. The double-reinforced fiberglass mesh gave me confidence before even making a cut.

As I set it on my miter saw, the 10-inch diameter and 3/32-inch thickness felt just right—solid but not overly bulky.

When I started cutting through some steel angle iron, I was surprised by how smooth and fast it sliced through. The resin-bonded aluminum-oxide grain really lives up to its promise of quick cutting.

I appreciated how minimal the sparks and heat were, thanks to the blade’s design.

The arbor reinforced with metal meant I didn’t worry about wobble or looseness during use. I also liked that it’s a Type 1 blade, made specifically for cutting ferrous metals, so I didn’t have to worry about safety or durability issues.

It felt like a reliable tool that would last through many projects.

However, I did notice that it’s not suitable for high-speed saws, so I kept that in mind to avoid any mishaps. Also, while it’s great for steel and sheet metal, it’s not a versatile blade for other materials.

Still, for the price and performance, this blade easily became my go-to for metal cutting jobs.

Overall, the IVY Classic Swift Cut blade feels like a smart upgrade for anyone tackling ferrous metals regularly. It’s tough, efficient, and built for safety—making those metal cuts a lot less daunting.

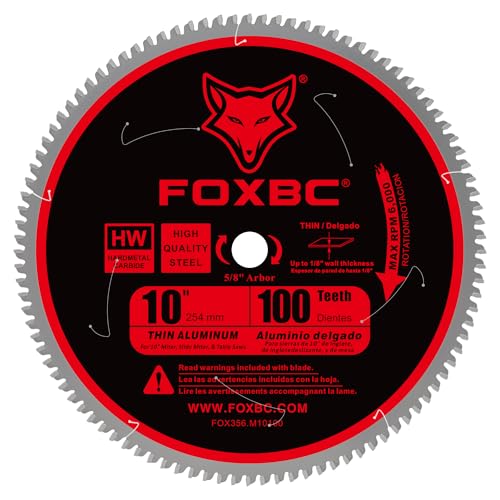

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Quiet and low vibration

- ✓ Long-lasting durability

- ✕ Higher price point

- ✕ Not for ferrous metals

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

Finally getting my hands on the FOXBC 10-Inch Saw Blade with 100 Teeth felt like unlocking a secret weapon for aluminum work. The moment I unboxed it, I noticed how thin and precise the blade is, with a sleek, durable appearance.

The laser-cut stabilizer vents caught my eye right away, promising quieter cuts with less vibration. I was eager to see if it would live up to those claims.

Using this blade, I was impressed by how smoothly it sliced through aluminum up to 1/8 inch thick. The triple chip grind teeth really delivered clean, burr-free edges, making my finishing tasks much easier.

Whether I was working on extrusions or small copper pipes, the blade maintained its sharpness without any noticeable wobble or burn marks.

What stands out is how well it handles different thicknesses—medium and thick aluminum cut effortlessly without sluggishness. The 0.095-inch kerf reduced waste, and I appreciated how compatible it was with my existing saws, from Makita to DeWalt.

It felt solid, and I could tell it was built from high-density tungsten carbide, which should give it a long life even with frequent use.

On the downside, the price is a bit higher than basic blades, but that’s expected given its quality and durability. Also, it’s specialized for non-ferrous metals, so don’t expect it to cut steel or other ferrous materials.

Overall, this blade transformed my aluminum cutting experience—fast, clean, and reliable. If you often work with aluminum or similar metals, it’s a smart investment that really pays off in performance.

What Factors Should You Consider When Choosing a Metal Cutting Blade for a Miter Saw?

When choosing the best metal cutting blade for a miter saw, several key factors should be considered to ensure optimal performance and results.

- Blade Material: The material of the blade affects its durability and cutting efficiency. Blades made of high-speed steel (HSS) are great for general use, while carbide-tipped blades offer better longevity and can cut through harder metals effectively.

- Tooth Count: The number of teeth on the blade impacts the finish of the cut. A blade with a higher tooth count provides a smoother finish and is ideal for thinner materials, while a lower tooth count is better for faster cuts in thicker metals.

- Kerf Width: The kerf width refers to how much material is removed during the cut. A thinner kerf blade reduces waste and requires less power to operate, making it suitable for precise cuts, while a thicker kerf blade is more robust and can handle tougher materials.

- Blade Diameter: The diameter of the blade must match the specifications of the miter saw for compatibility. Larger blades can cut thicker materials, but they also require more power and may be less manageable for intricate cuts.

- RPM Rating: It’s essential to check the blade’s recommended RPM rating to ensure it is compatible with the miter saw’s motor speed. Using a blade at an inappropriate RPM can lead to inefficient cutting or even dangerous situations.

- Type of Metal: Different types of metals, such as aluminum, steel, or stainless steel, require specific blade designs. For instance, blades designed for aluminum often have unique tooth geometry to prevent clogging, while those for stainless steel need to be tougher to withstand the material’s hardness.

- Coating: Some blades come with special coatings, such as titanium or anti-friction coatings, which can enhance performance by reducing friction and preventing corrosion. These coatings can extend the life of the blade and improve cutting efficiency.

What Are the Different Types of Metal Cutting Blades Used in Miter Saws?

The different types of metal cutting blades used in miter saws include:

- Tungsten Carbide Tipped Blades: These blades feature tips made from tungsten carbide, which provides exceptional durability and cutting performance on various metals.

- High-Speed Steel (HSS) Blades: Made entirely from high-speed steel, these blades are designed for precision cutting and can handle lighter metal applications.

- Cermet Blades: Combining ceramic and metal materials, cermet blades offer a balance of sharpness and wear resistance, making them suitable for cutting both ferrous and non-ferrous metals.

- Diamond Blades: Equipped with diamond segments, these blades excel in cutting through hard materials such as stainless steel and are ideal for heavy-duty applications.

- Bi-Metal Blades: These blades combine two types of metal, offering flexibility and toughness, making them particularly effective for cutting through various metals without breaking.

Tungsten Carbide Tipped Blades: These blades are a popular choice for metal cutting because they maintain their sharpness longer than standard steel blades. The tungsten carbide tips can withstand the heat generated during cutting, resulting in cleaner cuts and extended blade life.

High-Speed Steel (HSS) Blades: HSS blades are known for their ability to retain hardness at elevated temperatures, which makes them effective for lighter cutting tasks. While they may not last as long as carbide-tipped blades, they are often more affordable and suitable for hobbyists or less demanding applications.

Cermet Blades: These blades incorporate a unique blend of ceramic and metal materials, offering a sharp edge that is resistant to wear. They are particularly effective for achieving high-quality finishes on both ferrous and non-ferrous metals, making them versatile for various projects.

Diamond Blades: Diamond blades are designed for cutting hard materials and are ideal for professionals dealing with tough metals. The diamond segments provide aggressive cutting power, ensuring longevity and efficiency in heavy-duty applications.

Bi-Metal Blades: Bi-metal blades are constructed from two different metals, combining strength and flexibility. This design allows them to absorb shock and resist breakage, making them a reliable option for cutting through various metal types, including thicker materials.

How Do Carbide-Tipped Blades Compare to High-Speed Steel Blades?

| Feature | Carbide-Tipped Blades | High-Speed Steel Blades |

|---|---|---|

| Material | Made with carbide tips for enhanced cutting performance. | Constructed from high-speed steel, suitable for general use. |

| Durability | Highly durable, withstands heat and wear effectively. | Less durable, can dull faster and is prone to damage under heavy use. |

| Cut Quality | Provides finer cuts and minimizes chipping or tearing. | Good for rough cuts but may produce a rougher finish. |

| Cost | Generally more expensive due to advanced material and manufacturing. | More affordable, making it accessible for casual users. |

| Applications | Ideal for cutting metals, plastics, and hardwoods. | Best for softer materials and general woodworking. |

| Lifespan | Last significantly longer, often several times more than HSS blades. | Shorter lifespan, typically needing replacement more frequently. |

| Compatibility | Can be used with most miter saws and is versatile across various materials. | Limited to softer materials, may not perform well with metals. |

What Are the Advantages of Using Diamond Blades for Metal Cutting?

The advantages of using diamond blades for metal cutting are numerous and significant for achieving high-quality results.

- Durability: Diamond blades are known for their exceptional durability, allowing them to last longer than traditional metal cutting blades. This longevity means reduced downtime and less frequent replacements, which can save costs in the long run.

- Precision Cutting: These blades provide superior precision due to their design and material properties. The diamond edge allows for finer cuts with less chipping and burrs, making them ideal for applications where accuracy is crucial.

- Heat Resistance: Diamond blades have excellent heat dissipation properties, which minimizes the risk of overheating during prolonged cutting sessions. This helps to maintain the integrity of both the blade and the material being cut, preventing warping or damage.

- Versatility: Suitable for cutting a variety of metals, including stainless steel and aluminum, diamond blades are versatile tools in any metalworking shop. This capability makes them a preferred choice for professionals who work with different types of materials.

- Reduced Vibration: Diamond blades tend to produce less vibration compared to other types of metal cutting blades. This stability leads to smoother cuts and less strain on both the equipment and the user, enhancing overall cutting efficiency.

- Cleaner Cuts: The design of diamond blades allows for cleaner cuts with minimal finishing required. This benefit is particularly valuable in applications where surface quality is paramount, saving time on post-cutting processes.

Which Brands Are Known for Producing High-Quality Metal Cutting Blades for Miter Saws?

Several brands are recognized for producing high-quality metal cutting blades for miter saws:

- DeWalt: DeWalt is renowned for its durable and efficient cutting tools, including metal cutting blades specifically designed for miter saws. Their blades often feature carbide-tipped teeth that enhance cutting precision and longevity, making them ideal for various metal applications.

- Milwaukee: Milwaukee blades are designed with innovative technology that promotes faster and smoother cuts through metal. Their offerings often include specialized features like anti-friction coatings and optimized tooth geometry, which help reduce heat buildup and increase blade life.

- Makita: Makita is known for its high-performance tools, and its metal cutting blades reflect this quality. These blades typically incorporate high-grade materials and advanced manufacturing processes to ensure clean cuts and minimal burrs, making them suitable for professional and DIY use alike.

- Bosch: Bosch produces a range of metal cutting blades that stand out for their precision and reliability. With features such as high tooth counts and premium carbide tips, these blades provide exceptional cutting performance and are designed to handle various metal types effectively.

- Freud: Freud blades are crafted with a focus on cutting efficiency and durability. Their metal cutting blades often feature advanced tooth designs that reduce friction and enhance cutting speed, making them a preferred choice for those needing clean and accurate cuts in metal materials.

What Speed and Thickness Specifications are Optimal for Metal Cutting Blades?

When selecting a metal cutting blade for a miter saw, understanding speed and thickness specifications is key to achieving precise cuts.

Speed:

– The optimal speed for metal cutting blades typically ranges from 3,000 to 4,000 RPM (revolutions per minute). Higher RPMs allow for smoother cuts and reduced burr formation.

– It’s important to ensure your miter saw is compatible with the blade’s speed rating, as exceeding this can lead to blade damage or hazardous situations.

Thickness:

– The thickness of the blade often correlates with the thickness of the metal being cut.

– A blade with a thicker kerf (about 1/8 inch) is suitable for cutting through thicker metals, such as steel or aluminum profiles, while a thinner kerf (around 1/16 inch) is ideal for lighter gauge metals.

– Additionally, consider the TPI (teeth per inch); blades with 10-14 TPI are effective for cutting metal, as they provide a balance between speed and finish quality.

Careful selection based on these specifications ensures efficient cutting while maintaining the integrity of both the blade and the workpiece.

How Can You Extend the Life of Your Metal Cutting Blade?

To extend the life of your metal cutting blade, consider the following practices:

- Use the Correct Blade: Always use a blade specifically designed for cutting metal, as these blades are engineered with materials and tooth designs that withstand the unique stresses of metal cutting.

- Maintain Proper Speed: Ensure your miter saw is set to the appropriate RPM for the metal blade being used, as running the blade too fast can cause overheating and premature wear.

- Keep the Blade Clean: Regularly clean your blade to remove any built-up metal shavings or debris, which can affect cutting performance and increase the risk of blade damage.

- Utilize Lubrication: Applying cutting fluid or lubricant during the cutting process can reduce friction, dissipate heat, and prolong the life of the blade.

- Make Smooth Cuts: Avoid forcing the blade through the material; instead, let the saw do the work and maintain a steady, smooth cutting motion to prevent undue strain on the blade.

- Store Blades Properly: When not in use, store metal cutting blades in a protective case to prevent physical damage and corrosion, which can impair their effectiveness.

- Sharpen When Necessary: Regularly inspect the blade for dullness and have it sharpened as needed, as a sharp blade is more efficient and reduces the risk of damage during cuts.

Using the Correct Blade ensures that you are equipped with the right tool for the job, as metal cutting blades have specific features like carbide tips and a higher tooth count that make them suitable for cutting through various types of metals. Maintaining Proper Speed is critical; every blade has a recommended RPM, and exceeding this can lead to overheating, warping, and reduced lifespan.

Keeping the Blade Clean is essential because accumulated debris can create friction and heat, which are detrimental to the blade’s longevity. Utilizing Lubrication during cuts helps to keep the blade cool and reduces wear, while Making Smooth Cuts by allowing the saw to perform naturally prevents unnecessary stress that could lead to blade failure.

Storing Blades Properly avoids damage from environmental factors, and Sharpening When Necessary keeps the blade in peak condition, as a sharp blade cuts more efficiently and requires less force, reducing the risk of damage during use.

Related Post: