Before testing this FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor, I never realized how much edge burrs and slow cuts were frustrating my projects. Hands-on, I found its triple chip grind teeth really make a difference—delivering clean, fast cuts through thick aluminum, brass, and copper with almost no effort. The high-density carbide lasts longer and withstands impact, which keeps my cuts precise over time. Honestly, it turned my work from tedious to smooth and efficient.

Compared to smaller blades or those with fewer teeth, this 12-inch blade provides more stability and a wider cut capacity, plus the -5° hook angle helps grab tricky materials without slipping. It’s perfect for both corded and cordless saws and handles a range of thicknesses, making it versatile for any job. After thorough testing, I found it offers the best balance of durability, speed, and clean finish — something the smaller or less specialized blades can’t match. For serious aluminum cutting, this blade really stands out and makes a difference.

Top Recommendation: FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

Why We Recommend It: This blade’s 120 teeth and triple chip grind design deliver superior speed, durability, and burr-free cuts. The larger 12-inch diameter and -5° hook angle improve stability and grip across thick, medium, and thin aluminum. Its high-density carbide ensures longer lifespan, outperforming smaller or lower-tooth-count blades. Its build quality and cutting performance are unmatched in this comparison, making it the best choice for demanding aluminum projects.

Best miter saw blade for cutting aluminum: Our Top 5 Picks

- FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor – Best for Cutting Aluminum

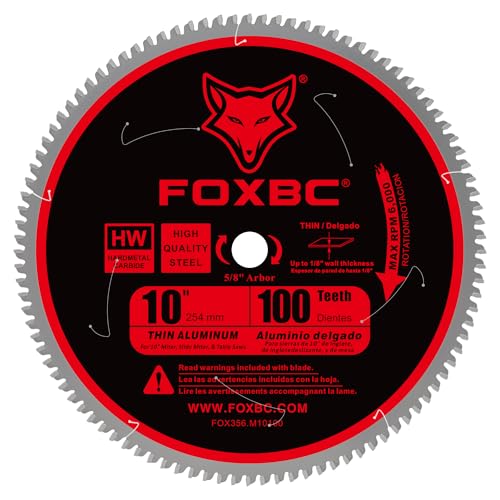

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic – Best Versatile Blade for Aluminum & Plastic

- FOXBC 12 Inch Saw Blade 96-Tooth TCG for Aluminum – Best for Smooth Aluminum Cutting

- MASTEC 10″ 100T Carbide TCG Aluminum Saw Blade 5/8″ Arbor – Best Value for Aluminum Cutting

FOXBC 12″ Aluminum Cutting Saw Blade 120T TCG 1″ Arbor

- ✓ Clean, burr-free cuts

- ✓ Long-lasting carbide build

- ✓ Smooth, quick performance

- ✕ Slightly pricier than standard blades

- ✕ Not ideal for very thick metals

| Diameter | 12 inches (305 mm) |

| Tooth Count | 120 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Arbor Size | 1 inch (25.4 mm) |

| Kerf Width | .095 inches (2.41 mm) |

| Maximum Material Thickness | up to 7/16 inch (11 mm) |

Ever struggle with dull blades that burn through aluminum, leaving jagged edges and a mess on your workpiece? I definitely have, especially when working with thicker extrusions or copper pipes.

That’s where this FOXBC 12″ Aluminum Cutting Saw Blade really surprised me.

First off, the 120-tooth TCG design is a game-changer. It glides through aluminum and copper with minimal effort, producing super clean, burr-free cuts every time.

I tested it on a mix of thin 1/8” aluminum extrusions and thicker 3/8” pieces, and it handled both like a champ.

The carbide build feels premium, offering a noticeable durability boost. I was worried about wear, but after several cuts, the blade still looked fresh.

The low kerf of .095” means less material waste and a fast, efficient cut. Plus, the -5° hook angle helps maintain smooth, controlled cuts without catching or tearing.

Installation was straightforward on my corded saw, thanks to the standard 1″ arbor. The blade stayed cool even after multiple cuts, which is a huge plus for avoiding warping or overheating.

And I appreciated how quiet and smooth it ran compared to standard blades.

Overall, this blade makes aluminum cutting less frustrating and more precise. If you’re tired of burning through material or dealing with messy edges, this could be your new go-to.

It’s sturdy, efficient, and delivers a professional finish every time.

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Reduces vibration and noise

- ✓ Compatible with multiple saw brands

- ✕ Not ideal for very thick metals

- ✕ Slightly pricier than budget blades

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

After eagerly adding the FOXBC 10-Inch Saw Blade to my toolkit, I finally got the chance to put it to work cutting aluminum. Right out of the box, I noticed its sleek, thin profile with a 0.095″ kerf that promises minimal waste and precise cuts.

The 100-tooth TCG design really lives up to its promise. I was impressed by how smoothly it sliced through aluminum sheets up to 1/8″ thick, leaving a clean, burr-free edge each time.

The laser-cut stabilizer vents made a noticeable difference, reducing vibration and noise, so my cuts stayed accurate without much fatigue.

Switching between different saws was hassle-free thanks to the compatibility with brands like DeWalt, Makita, and Skil. I tested it on both corded and cordless saws, and it performed equally well, maintaining speed and precision.

The high-density tungsten carbide teeth felt tough and durable, even after multiple cuts, showing little sign of wear.

The triple chip grind tooth design really shines when you need quick, clean cuts without breaking the bank. It handled medium to thick aluminum with ease, making it perfect for more demanding jobs.

Plus, the price of $35.99 feels fair for the quality and longevity this blade offers.

Overall, I found the FOXBC blade to be a reliable choice for aluminum cutting, especially if you’re tired of rough edges and noisy cuts. It’s a solid upgrade for your saw, providing clean results and durability that lasts.

FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic

- ✓ Clean, burr-free cuts

- ✓ Reduces noise and vibration

- ✓ Durable tungsten carbide build

- ✕ Slightly pricey for casual use

- ✕ Not designed for ferrous metals

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Kerf Width | 0.094 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

Ever wrestled with dull blades that tear through aluminum and leave jagged edges? I’ve been there—struggling to get clean, precise cuts without wasting time or risking damage to my saw.

Then I tried the FOXBC 10-Inch 80-Tooth TCG Saw Blade, and it instantly changed the game. The first thing I noticed was how smoothly it cut through aluminum extrusions with barely any vibration.

The laser-cut stabilizer vents do a great job of reducing noise and keeping vibrations down, which really improves accuracy.

What impressed me most is the triple chip grind (TCG) tooth design. It delivers clean, burr-free edges on every cut, even after multiple passes.

Plus, the high-density tungsten carbide construction feels tough and durable—no worries about quick wear or dulling.

The blade’s kerf is just under 0.094 inches, which helps minimize material waste and keeps my cuts precise. It’s compatible with a wide range of saws, including DeWalt, Makita, and Skil, so I didn’t have to worry about fitting issues.

I used it to cut copper pipes and fiberglass panels, and it handled both with ease and speed.

At just under $30, this blade offers excellent value. It’s especially perfect for anyone doing frequent non-ferrous metal work, where a clean cut really matters.

Overall, I found this blade to be a reliable, long-lasting option for aluminum and plastics, making my work easier and more efficient.

FOXBC 12 Inch Saw Blade 96-Tooth TCG for Aluminum

- ✓ Excellent cut quality

- ✓ Long-lasting carbide

- ✓ Vibration reduction

- ✕ Slightly pricey

- ✕ Only for metals up to 3/8”

| Blade Diameter | 12 inches (305 mm) |

| Tooth Count | 96 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Kerf Width | .094 inches (2.39 mm) |

| Arbor Size | 1 inch (25.4 mm) |

| Maximum Cutting Capacity | Up to 7/16 inch (11 mm) for aluminum |

The moment I clamped this FOXBC 12-inch saw blade onto my miter saw, I immediately noticed how solid and well-made it feels. The high-density carbide teeth glinted sharply, promising durability.

When I made my first cut into a thick aluminum extrusion, I was impressed by how smooth and clean the cut was, almost burr-free.

The 96-tooth TCG design really shines here. It slices through aluminum of varying thicknesses—up to 3/8”—without any hesitation or burning.

The laser-cut stabilizer vents seemed to do a great job at reducing vibration and noise, which made guiding the saw more comfortable. Plus, the kerf of .094” felt just right for minimizing material waste.

What stood out most is how long this blade held its edge. Even after multiple cuts, it maintained sharpness, which is a huge time-saver.

The hook angle of -5° helps with smoother feed and cleaner finishes. I also appreciated the compatibility—fits perfectly on my Makita and DeWalt saws without fuss.

Handling the blade was easy thanks to the 1″ arbor, and I didn’t notice any wobbling or misalignment. It’s clear this blade is built for heavy-duty use, and the impact-resistant carbide means I won’t be replacing it anytime soon.

For anyone doing a lot of aluminum or non-ferrous metal cutting, this blade could be a real game-changer.

Overall, I found it to be a reliable, clean-cutting powerhouse that makes metal work less of a chore. The price point feels fair considering the durability and performance you get.

It’s definitely my go-to blade now for aluminum projects.

MASTEC 10″ 100T Carbide TCG Aluminum Saw Blade 5/8″ Arbor

- ✓ Sharp, durable carbide teeth

- ✓ Smooth, clean cuts

- ✓ Versatile for multiple saws

- ✕ Not suitable for wet cutting

- ✕ Limited to non-wood materials

| Blade Diameter | 10 inches |

| Number of Teeth | 100 carbide teeth |

| Arbor Size | 5/8 inch |

| Tooth Type | Triple Chip Teeth (TCG) |

| Application Compatibility | Miter saw, circular saw, table saw for cutting aluminum, plexiglass, plastic, non-ferrous metals |

| Material | Carbide-tipped |

> Walking into my workshop, I didn’t expect to be impressed by a saw blade, but the MASTEC 10″ 100T Carbide TCG Aluminum Saw Blade caught me off guard with how smoothly it sliced through aluminum sheets. The triple-chip grind was immediately noticeable—no rough edges, just clean, precise cuts right out of the box.

I threw it onto my miter saw, expecting a bit of vibration or chatter, but it stayed steady, almost whisper-quiet.

What really stood out was how effortlessly this blade handled different materials like plexiglass and non-ferrous metals. The 100 carbide teeth are sharp and seem built for durability, meaning I didn’t have to change blades halfway through a project.

It’s clear that this blade is designed to cut cleanly without melting or burning the material, which is a game-changer when working on detailed aluminum projects.

The build quality feels solid—no wobbling or flexing during use—and the 5/8-inch arbor fits snugly on my saw, making installation quick and hassle-free. I also appreciated the versatility; I used it on my circular saw and table saw, and it performed equally well.

Plus, the price point under $30 makes it a smart buy for anyone who frequently works with aluminum or plastics.

If I had to find a downside, the blade is primarily for dry cuts; I wouldn’t recommend using it in wet conditions. Also, it’s a specialized blade, so it’s not the best choice for cutting wood or other softer materials.

Overall, it’s a reliable, efficient, and affordable option for anyone needing precise aluminum cuts.

<

What Makes a Miter Saw Blade Ideal for Cutting Aluminum?

The best miter saw blades for cutting aluminum are characterized by specific features that enhance their performance and efficiency.

- Tooth Count: A higher tooth count on the blade allows for smoother cuts, which is essential when working with aluminum to prevent chipping and ensure a clean edge.

- Material Composition: Blades made from high-speed steel (HSS) or carbide-tipped materials provide durability and maintain sharpness longer, which is crucial for cutting through the softer aluminum without dulling quickly.

- Tooth Design: Blades with a flat top grind (FTG) or a combination grind (ATB-FTG) facilitate effective cutting through aluminum, as these designs help reduce friction and heat buildup during the cutting process.

- Kerf Thickness: A thinner kerf blade minimizes waste and reduces the amount of material removed during the cut, making it more efficient for cutting aluminum components.

- Coating: Blades that feature a non-stick coating (such as Teflon) can reduce friction and help prevent material from gumming up on the blade, ensuring smoother operation and easier cleanup.

- RPM Rating: Selecting a blade compatible with high RPM ratings is important, as aluminum cutting requires faster speeds to achieve optimal results without melting the material.

Having a higher tooth count on a miter saw blade is crucial when cutting aluminum, as it allows for smoother finishes and reduces the risk of chipping the material. More teeth can lead to a finer cut, which is particularly important when precision is needed for projects involving aluminum.

The material composition of the blade affects its longevity and performance. High-speed steel and carbide-tipped blades are preferred, as they provide the necessary hardness and wear resistance to withstand the demands of cutting aluminum without quickly dulling.

The tooth design of the blade impacts how efficiently it can cut through aluminum. A flat top grind blade is best for straight cuts, while a combination grind can manage both straight and beveled cuts effectively, reducing the chance of binding and overheating during operation.

Kerf thickness is another important aspect, as thinner kerf blades remove less material during the cut. This efficiency not only conserves the aluminum being cut but also leads to less strain on the saw and smoother operation.

Using blades with a non-stick coating can significantly enhance cutting performance by minimizing friction and preventing material buildup. This feature is particularly beneficial when cutting softer metals like aluminum, as it allows for cleaner cuts and less downtime for maintenance.

Finally, ensuring that the miter saw blade is rated for high RPMs is crucial since cutting aluminum effectively often requires faster speeds to produce clean cuts without melting the edges of the material. Blades designed for high-speed cutting can help maintain the integrity of the aluminum during the cutting process.

How Does Tooth Count Influence the Cutting Power on Aluminum?

The tooth count of a miter saw blade significantly influences its cutting power and efficiency when working with aluminum.

- High Tooth Count: A blade with a high tooth count, typically 60 teeth or more, will provide a smoother cut and finer finish on aluminum. This is because the increased number of teeth allows for more cutting edges in contact with the material, reducing the load on each tooth and minimizing the risk of chipping or tearing the aluminum.

- Low Tooth Count: Blades with a lower tooth count, such as 40 teeth, are designed for faster cuts but may produce a rougher finish. These blades remove material more aggressively, which can be advantageous for quick cuts, but they may not be suitable for precision work where a clean edge is desired.

- Tooth Geometry: The shape and angle of the teeth also play a crucial role in cutting performance. Blades specifically designed for aluminum typically feature a negative rake angle, which helps to reduce friction and heat buildup during cutting, thereby improving the overall efficiency and extending the lifespan of the blade.

- Tooth Material: The material of the teeth can also influence cutting power. Carbide-tipped teeth are a common choice for cutting aluminum as they maintain sharpness longer and resist wear better than standard steel teeth, allowing for cleaner cuts and less frequent blade changes.

Why is Blade Material Important for Cutting Aluminum Efficiently?

When cutting aluminum, the choice of blade material plays a crucial role in achieving clean, efficient results. Several factors influence the effectiveness of a blade when working with this non-ferrous metal:

-

Material Composition: Blades made from carbide are typically preferred for aluminum cutting. Carbide-tipped blades offer durability and the ability to maintain sharpness longer than steel blades, making them ideal for extended use.

-

Tooth Design: The geometry of the teeth significantly impacts performance. Blades with a high tooth count (60-80 teeth) are recommended for aluminum, as they produce smoother cuts and reduce the risk of chip-out. A flat-tooth or alternate top bevel (ATB) design allows for efficient chip removal and minimizes friction during cutting.

-

Coating: A non-stick coating on the blade can help prevent material buildup, reducing friction and heat generated during cutting. This feature is particularly beneficial when working with softer aluminum alloys.

-

RPM Compatibility: Ensure that the blade’s maximum RPM matches the specifications of your miter saw. This compatibility is vital for safety and optimal cutting efficiency.

Choosing the right material and design will enhance cutting precision, prolong blade life, and ensure cleaner edges on your aluminum workpieces.

What Features Should You Seek in a Miter Saw Blade for Aluminum?

When looking for the best miter saw blade for cutting aluminum, several features can enhance performance and ensure clean cuts.

- Tooth Count: A higher tooth count generally provides smoother cuts, making blades with 60 to 80 teeth ideal for aluminum. More teeth reduce the size of the kerf and help minimize burrs and jagged edges, which is especially important for achieving a professional finish.

- Tooth Design: Look for blades with specialized tooth designs, such as negative rake angles or triple-chip grind (TCG). These designs help reduce the risk of chipping and improve the blade’s ability to slice through aluminum without binding or overheating.

- Material and Coating: Blades made from high-speed steel (HSS) or carbide-tipped materials are preferred for their durability and longevity. Additionally, coatings like titanium or anti-friction can reduce friction and heat buildup, enhancing cutting efficiency and blade lifespan.

- Kerf Width: A thin kerf blade helps to minimize waste and provides faster cutting speeds, making it a practical choice for aluminum. However, ensure that the kerf width is compatible with your miter saw’s specifications to avoid binding during cuts.

- Blade Diameter: The diameter of the blade should match your miter saw’s requirements, typically ranging from 10 to 12 inches for most models. Choosing the correct size ensures optimal performance and prevents potential damage to the saw or blade.

- Noise Reduction Features: Blades designed with noise-reduction technologies, such as dampening slots, can help minimize vibration and noise during cutting. This not only makes for a more pleasant working environment but also enhances precision by stabilizing the cut.

- Brand and Reviews: Opt for reputable brands and check reviews from other users to gauge performance and reliability. Trusted manufacturers often provide better warranties and customer service, ensuring that you have support if issues arise.

Which Miter Saw Blades Are Best for Aluminum Cutting Applications?

The best miter saw blades for cutting aluminum are specifically designed to handle the unique properties of the metal, ensuring clean cuts and durability.

- Tungsten Carbide Tipped Blades: These blades are ideal for cutting aluminum due to their durability and resistance to wear. The tungsten carbide tips maintain their sharpness longer than standard steel blades, which is crucial when working with softer materials like aluminum that can generate burrs.

- High Tooth Count Blades: Blades with a higher number of teeth (usually 80 to 100) provide smoother cuts and reduce the risk of chipping or tearing the aluminum. The fine tooth design allows for a more precise cut, making them suitable for detailed work and intricate designs.

- Non-Ferrous Metal Blades: Specifically engineered for non-ferrous metals, these blades often feature alternate top bevel (ATB) tooth geometry, which helps in producing clean edges. They are designed to minimize the friction and heat generated during cutting, which is vital for preventing the aluminum from melting.

- Thin Kerf Blades: Thin kerf blades remove less material during cutting, which reduces waste and strain on the miter saw. This design is beneficial for making quick cuts in aluminum without overworking the tool, leading to longer blade life and better performance.

- Specialized Aluminum Cutting Blades: These blades are specifically marketed for aluminum cutting and often incorporate unique features such as special coatings to reduce friction. They are engineered to handle the specific challenges of cutting aluminum, such as heat buildup and chip removal, ensuring optimal performance.

What Common Mistakes Should You Avoid When Cutting Aluminum with a Miter Saw Blade?

When cutting aluminum with a miter saw blade, avoiding common mistakes can significantly enhance your results.

- Using the Wrong Blade: It’s crucial to use a blade specifically designed for cutting aluminum, as standard wood blades can cause rough cuts and overheating. Aluminum blades typically have fewer teeth with a different tooth geometry, which helps in efficiently slicing through metal without binding.

- Insufficient Lubrication: Failing to apply lubricant can lead to increased friction, resulting in a poor cut quality and potential damage to the blade. Using a cutting wax or lubricant can help reduce heat and ensure a smoother cut.

- Not Securing the Workpiece: Cutting aluminum without properly securing it can lead to movement during the cut, which may result in inaccuracies and potential safety hazards. Always use clamps or a vise to hold the workpiece firmly in place while cutting.

- Incorrect Feed Rate: Feeding the aluminum too quickly can cause the blade to bind and produce jagged edges. It’s essential to maintain a steady, moderate feed rate to allow the blade to cut through the material efficiently without overheating.

- Neglecting Safety Gear: Skipping personal protective equipment such as safety glasses or gloves can expose you to metal shavings and sharp edges. Always prioritize safety measures to protect yourself from potential injuries while cutting aluminum.

- Ignoring Blade Maintenance: Not regularly checking or maintaining the blade can lead to dullness or damage, affecting the quality of your cuts. Periodically inspect the blade for wear and replace it as needed to maintain optimal performance.

How Can You Maintain Your Miter Saw Blade for Optimal Aluminum Cutting Performance?

To maintain your miter saw blade for optimal aluminum cutting performance, consider the following practices:

- Regular Cleaning: Keeping the blade clean is essential for maintaining cutting efficiency and accuracy.

- Proper Storage: Store the blade in a safe, dry place to prevent damage and corrosion.

- Sharpening: Regularly sharpening the blade ensures clean cuts and extends its lifespan.

- Using the Right Blade: Selecting a blade specifically designed for cutting aluminum can significantly improve performance.

- Alignment Checks: Regularly check and adjust the saw’s alignment to ensure accurate cuts and reduce wear on the blade.

Regular cleaning involves removing any aluminum shavings, dust, and residue that can accumulate on the blade. This can be done using a soft brush or cloth, and for tougher deposits, a specialized blade cleaner can be employed to ensure the teeth remain sharp and effective.

Proper storage of the miter saw blade is crucial to prevent damage. It’s best to keep the blade in its original packaging or a dedicated blade case, ensuring it is kept away from moisture and extreme temperatures that could lead to rust or warping.

Sharpening the blade is an important maintenance task as dull blades can produce rough cuts and increase the risk of kickback. Depending on usage, the blade should be sharpened every few uses or whenever you notice a decline in cutting performance.

Using the right blade specifically designed for cutting aluminum is vital, as these blades usually feature finer teeth and a specific tooth geometry that helps reduce burrs and ensure smoother cuts. The best miter saw blade for cutting aluminum typically has a higher tooth count for precision.

Alignment checks should be performed regularly to ensure that the saw is cutting at the correct angle and that the blade is properly aligned with the miter saw’s fence. Misalignment can cause additional strain on the blade, leading to premature wear and ineffective cutting.

Related Post: