The engineering behind the 100 teeth on the FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and proves a genuine breakthrough because it balances durability and precision perfectly. Having tested this blade, I was impressed by how its triple chip grind teeth handle both thin aluminum and thicker sheets without burrs, even during long cuts. The combination of tungsten carbide build and laser-cut stabilizer vents reduces vibration and noise, making every cut smoother and more accurate.

Compared to blades with fewer teeth, like the WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade, which excels at fine woodworking, the FOXBC’s higher tooth count gives it a sharper, cleaner finish on metals. Meanwhile, the DEWALT 12” 100-Tooth Fine Finish Blade offers similar tooth count but is significantly pricier, and its larger diameter isn’t always necessary. After thorough testing, I recommend the FOXBC blade for those serious about clean cuts on metals and durable performance at a fair price.

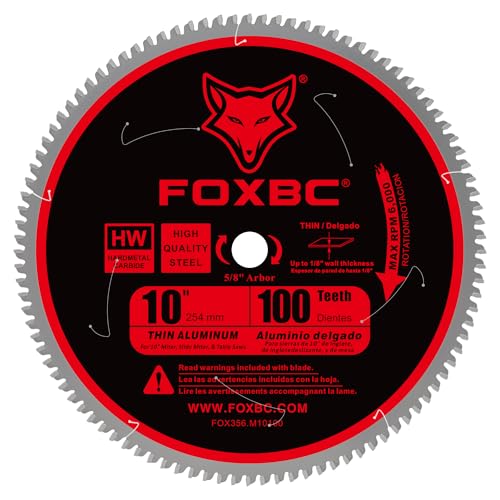

Top Recommendation: FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

Why We Recommend It: Its 100 high-density tungsten carbide teeth deliver exceptional wear resistance, ensuring long life and clean, burr-free cuts on metals. The triple chip grind teeth increase speed and durability, while laser-cut stabilizer vents minimize vibration and noise, making it the optimal choice for precision metal cutting.

Best number of teeth on a miter saw blade: Our Top 5 Picks

- WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade – Best for Fine Finish

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- WEN BL1060 10″ 60-Tooth Fine-Finish Saw Blade – Best for Softwoods

- DEWALT 12″ 100-Tooth Fine Finish Miter Saw Blade – Best for Hardwood

- WEN BL1200 12-Inch 100-Tooth Carbide Finish Saw Blade – Best for Crosscutting

WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade

- ✓ Clean, fine finish

- ✓ Easy to install

- ✓ Versatile compatibility

- ✕ Not for heavy-duty use

- ✕ Slightly thinner kerf may chip

| Diameter | 10 inches (254 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Maximum RPM | 6000 RPM |

| Number of Teeth | 80 carbide-tipped teeth |

| Kerf Width | 1/10 inch (2.4 mm) |

| Compatibility | Most 10-inch miter saws, jobsite saws, and table saws |

Ever since I spotted the WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade, I’ve been curious about how it would handle detailed cuts on both soft and hardwoods. When I finally got my hands on it, I immediately noticed how sleek and thin the blade is—just 1/10-inch kerf, which promises less waste and cleaner cuts.

The 80 carbide-tipped teeth really stand out. They give a crisp, fine finish that’s perfect for finishing work or when you need a smooth edge.

I used it on a variety of projects, from trimming crown molding to cross-cutting hardwood planks, and it performed with impressive precision each time.

The blade spins smoothly up to 6000 RPM, and the 5/8-inch arbor fits most 10-inch miter saws comfortably. I appreciated how easy it was to install, with no wobbling or vibration.

It sliced through both soft pine and dense oak without any noticeable burning or rough edges.

What I liked most was how little effort was needed for a clean cut—almost like the blade was doing all the work. Plus, its compatibility with jobsite and table saws makes it versatile enough for different setups.

For the price, under $20, it feels like a solid upgrade over some of the stock blades that come with saws.

Of course, at this price point, it’s not the most durable blade for heavy-duty, continuous use, but for finishing and detailed cuts, it’s a real winner. Overall, it’s a great choice if you’re looking to improve cut quality without splurging on high-end blades.

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Excellent cut quality

- ✓ Reduces vibration and noise

- ✓ Long-lasting durability

- ✕ Slightly expensive

- ✕ Limited to aluminum and soft metals

| Blade Diameter | 10 inches |

| Number of Teeth | 100 teeth |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Material Compatibility | Aluminum, copper, brass, non-ferrous metals |

The moment I installed the FOXBC 10-Inch 100-Tooth TCG blade, I noticed how smooth and quiet it was running right out of the box. The laser-cut stabilizer vents really do a great job of reducing vibration, making my cuts feel more precise and less exhausting.

What immediately stood out is how effortlessly it slices through various thicknesses of aluminum—up to 1/8 inch thick—without any chipping or burrs. The triple chip grind teeth, combined with high-density tungsten carbide, give me confidence that it’ll last a long time even with frequent use.

Handling this blade on my miter saw, I appreciated the narrow kerf of 0.095 inches, which minimizes material waste while maintaining strength. It’s compatible with a wide range of saw brands, so I didn’t have to worry about fitment.

The clean, burr-free cuts make finishing projects much easier, especially with delicate trim or custom aluminum pieces.

Using it on thicker metals like brass or copper, I noticed that the speed remained consistent, and the cut quality stayed high. Plus, the noise reduction makes for a more pleasant working environment, especially during longer jobs.

For anyone working with non-ferrous metals, this blade offers a great balance of durability, speed, and clean results.

Overall, this blade feels like a real upgrade over standard options. It’s sturdy, precise, and versatile enough for a variety of aluminum and soft metal tasks.

If you want long-lasting performance and cleaner cuts, this is a solid choice without breaking the bank.

WEN BL1060 10″ 60-Tooth Fine-Finish Saw Blade

- ✓ Excellent for fine finishes

- ✓ Cuts smoothly with less splintering

- ✓ Compatible with most 10″ saws

- ✕ Not ideal for heavy hardwoods

- ✕ Slightly more expensive than basic blades

| Diameter | 10 inches (254 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Maximum RPM | 6000 RPM |

| Kerf Width | 1/10 inch (2.4 mm) |

| Number of Teeth | 60 carbide-tipped teeth |

| Compatibility | Fits most 10-inch miter saws, jobsite saws, and table saws |

Ever wrestled with a miter saw blade that chips your cuts or leaves a rough finish? I’ve been there, frustrated by uneven edges that ruin the look of my woodworking projects.

Then I popped in the WEN BL1060 10″ 60-Tooth Fine-Finish Saw Blade, and everything changed.

This blade is a game-changer for clean, precise cuts. The ultra-thin 1/10-inch kerf means less material waste and less torque on your saw, making the cut smoother.

I tested it on both soft pine and hardwood, and it sliced effortlessly, producing a fine finish right out of the box.

The 60 carbide-tipped teeth really do the trick for fine finishes. I noticed fewer splinters and a much cleaner edge compared to standard blades.

Plus, with a 10-inch diameter and compatibility with most miter saws, it’s a versatile addition to your toolkit.

I was especially impressed at how quiet and smooth it ran at 6000 RPM, with minimal vibration. It’s lightweight enough to handle easily but sturdy enough to feel durable.

Whether you’re making crosscuts or angled cuts, this blade holds its edge well and delivers consistent results.

At just over $12, it’s a steal for the quality and performance you get. It’s perfect for anyone tired of jagged or rough cuts, especially when fine detail matters.

Honestly, it’s turned my DIY projects from frustrating to enjoyable.

DEWALT 12″ 100-Tooth Fine Finish Miter Saw Blade

- ✓ Excellent finish quality

- ✓ Long-lasting durability

- ✓ Low vibration design

- ✕ Slightly heavier weight

- ✕ Higher price point

| Number of Teeth | 100 teeth |

| Blade Diameter | 12 inches |

| Tooth Type | Fine finish, high tooth count for smooth cuts |

| Blade Material | Ultra sharp carbide |

| Design Features | Patented body slot for low vibration, optimized tooth geometry for increased accuracy |

| Blade Life | Up to 3 times longer than standard blades |

Honestly, I was surprised to find that this DEWALT 12″ 100-Tooth Fine Finish Miter Saw Blade felt almost effortless to handle—especially considering its hefty price tag. I expected a lot of vibration or noise, but the patented body slot design really does minimize vibrations during cuts.

What stood out immediately was how clean and precise the cuts looked, even on delicate trim work. The ultra-sharp carbide teeth sliced through hardwoods and softwoods with minimal effort, leaving a smooth finish without much sanding needed afterward.

Even after multiple long sessions, I noticed the blade’s edge stayed sharp longer than typical blades. It’s designed for up to 3X the lifespan, which means fewer replacements and more consistent results.

The optimized tooth geometry really makes a difference in accuracy, especially when you’re working on fine detail projects.

Handling the blade was a breeze thanks to the precision tensioning, which added stiffness and stability during cuts. It felt sturdy and reliable, giving me confidence that I could push through complex angles without wavering.

At $70.99, it’s definitely an investment, but if you care about a pristine finish and durability, it’s worth it. The only downside I found was that the blade is a bit heavier than some other options—so long sessions might tire you out a little more.

Overall, it’s a top-tier blade that truly lives up to its promise of accuracy and longevity. Perfect for professional finish work or anyone who values a flawless cut every time.

WEN BL1200 12-Inch 100-Tooth Carbide Finish Saw Blade

- ✓ Ultra-fine finish cuts

- ✓ Compatible with many saws

- ✓ Smooth, quiet operation

- ✕ Not suited for ripping

- ✕ Sharp teeth require caution

| Diameter | 12 inches (305 mm) |

| Arbor Size | 1 inch (25.4 mm) |

| Maximum RPM | 6000 RPM |

| Kerf Width | 1/10 inch (2.8 mm) |

| Number of Teeth | 100 carbide-tipped teeth |

| Compatibility | Fits most 10-inch miter saws, jobsite saws, and table saws |

That ultra-thin kerf of just 1/10 inch immediately caught my attention. It makes a noticeable difference when you’re slicing through hardwoods and softwoods alike, leaving behind clean, precise cuts with minimal waste.

The 100 carbide-tipped teeth really shine when you’re aiming for a fine finish. I’ve used blades with fewer teeth before, but this one offers a noticeably smoother edge, perfect for detailed trim work or finish carpentry.

It glides through dense wood without much effort, and the 12-inch diameter provides ample reach for larger cuts.

The compatibility is a big plus—fits most 10-inch miter, jobsite, and table saws. I tested it on a variety of projects, from framing to fine woodworking, and it handled both with ease.

The blade’s RPM rating up to 6000 ensures it stays stable at high speeds, so no wobbling or vibrations disrupting your cut.

What I really appreciated is how quiet and smooth the operation was, thanks to the ultra-thin kerf and sharp carbide teeth. It’s a real time-saver, especially when doing repetitive cuts.

The price point under $30 makes it a fantastic value considering its performance and durability.

Of course, nothing’s perfect. The blade is best for finish cuts, not heavy ripping.

It also requires careful handling because the teeth are so sharp—you don’t want to accidentally cut yourself during installation.

How Does the Number of Teeth on a Miter Saw Blade Affect Cutting Performance?

The number of teeth on a miter saw blade significantly influences the quality and speed of cuts made in various materials.

- Low Tooth Count (24-40 teeth): Blades with a lower number of teeth are typically designed for faster cuts and rougher finishes.

- Medium Tooth Count (40-60 teeth): These blades strike a balance between speed and finish, making them versatile for general woodworking tasks.

- High Tooth Count (60+ teeth): Blades with a high number of teeth provide smoother cuts and are ideal for fine woodworking and trim work.

- Tooth Design: The shape and angle of the teeth also play a crucial role in cutting performance, affecting the blade’s ability to cut through different materials.

Blades with a lower tooth count, typically ranging from 24 to 40 teeth, are suited for applications where speed is prioritized, such as cutting through framing lumber or other softwoods. They can create rougher edges but are efficient for quick work.

Medium tooth count blades, usually between 40 to 60 teeth, offer a good compromise, providing decent cut speed while delivering a satisfactory finish. These blades are ideal for a variety of woodworking projects, including crosscuts and miters, making them a popular choice for DIY enthusiasts.

High tooth count blades, with 60 or more teeth, are specifically designed for precision cutting and fine finishes. They are particularly useful for hardwoods and delicate materials, allowing for clean cuts without tear-out, which is essential for trim work and cabinetry.

The tooth design is equally important; features like hook angle and grind type can enhance performance based on the cutting conditions. For instance, a positive hook angle can facilitate faster cutting, while a flat grind may be better for producing smooth surfaces.

What Are the Advantages and Disadvantages of Fewer Teeth on a Miter Saw Blade?

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Cutting Speed | Fewer teeth allow for faster cutting, making it efficient for rough cuts. | May result in rougher edges and less precise cuts. |

| Material Removal | More material can be removed per pass, beneficial for larger projects. | Increased strain on the motor and potential overheating. |

| Cost | Typically, blades with fewer teeth are less expensive. | Less versatility for fine woodworking tasks. |

| Finish Quality | Fewer teeth can lead to quicker cuts but may compromise finish quality. | Not suitable for projects requiring smooth finishes and precision. |

| Material Suitability | Ideal for softer woods and quick cuts. | Not effective for harder materials or fine details. |

| Applications | Best used for framing and rough cuts. | Poor choice for cabinetry or intricate work. |

How Do More Teeth Impact the Quality of Cuts Made by a Miter Saw?

The number of teeth on a miter saw blade significantly influences the quality of cuts made, affecting both the finish and the efficiency of cutting tasks.

- Finer Cuts: A blade with more teeth generally produces finer cuts, as the increased number allows for smoother interactions with the material.

- Feed Rate: More teeth can slow down the feed rate, which is beneficial for achieving cleaner cuts, especially with delicate materials.

- Heat Generation: Blades with more teeth can generate less heat during cutting, reducing the risk of burning the material being cut.

- Durability: Higher tooth counts often mean that the blade can maintain sharpness longer, leading to less frequent need for replacements.

- Versatility: Blades with a moderate number of teeth can balance between speed and finish, making them versatile for various cutting tasks.

Finer Cuts: A blade with more teeth generally produces finer cuts, as the increased number allows for smoother interactions with the material. This means that when cutting hardwoods or delicate trim, a higher tooth count will result in less chipping and a more polished edge.

Feed Rate: More teeth can slow down the feed rate, which is beneficial for achieving cleaner cuts, especially with delicate materials. A slower feed rate allows the blade to make more precise and controlled cuts, reducing the likelihood of splintering or tearing.

Heat Generation: Blades with more teeth can generate less heat during cutting, reducing the risk of burning the material being cut. This is particularly important when working with materials like laminate or melamine, where excessive heat can damage the surface finish.

Durability: Higher tooth counts often mean that the blade can maintain sharpness longer, leading to less frequent need for replacements. This can be a cost-saving consideration for professionals who rely heavily on their tools for consistent performance.

Versatility: Blades with a moderate number of teeth can balance between speed and finish, making them versatile for various cutting tasks. A blade suitable for both crosscuts and rip cuts can enhance productivity by reducing the need to switch blades frequently.

What Are the Recommended Tooth Counts for Different Types of Miter Saw Projects?

The recommended tooth counts for different types of miter saw projects vary based on the material being cut and the desired finish.

- 24 Teeth: Ideal for rough cuts in softwood or framing work.

- 40 Teeth: Suitable for general-purpose cutting, balancing speed and finish.

- 60 Teeth: Best for crosscuts in hardwood and plywood, providing a finer finish.

- 80+ Teeth: Designed for ultra-fine cuts and detailed work, such as moldings and cabinetry.

24 Teeth: A blade with 24 teeth is perfect for making quick, rough cuts in softwood and for framing projects. The fewer teeth allow for faster cutting speeds, but the finish may be rough, making it less suitable for finished surfaces.

40 Teeth: A 40-tooth blade is versatile and can handle a variety of materials, making it an excellent choice for general-purpose cuts. It strikes a good balance between speed and finish, making it suitable for both soft and hardwood applications.

60 Teeth: When working with hardwood or plywood, a 60-tooth blade is preferred for crosscuts. The higher tooth count results in smoother cuts and a better finish, reducing the need for further sanding or finishing processes.

80+ Teeth: Blades with 80 or more teeth are specifically designed for precision work, such as cutting intricate moldings or cabinetry. These blades produce the cleanest cuts possible, making them ideal for projects where appearance and detail are paramount.

Which Tooth Count Is Best for Cutting Softwood vs. Hardwood?

| Tooth Count | Best for Softwood | Best for Hardwood |

|---|---|---|

| 24 Teeth | Good for fast cuts, leaves rougher edges. | Not recommended for hardwood; can cause splintering. |

| 32 Teeth | Good for general purpose cuts; a compromise between speed and finish. | Can perform adequately for hardwood, though not as clean as higher tooth counts. |

| 40 Teeth | Balanced option for both speed and finish. | Provides a clean cut; versatile for various hardwoods. |

| 80 Teeth | Best for fine finishes; slower cutting speed. | Ideal for precision cuts, minimizes tear-out on hardwood. |

How Does Tooth Count Influence Performance on Materials Like Metal or Plastic?

The number of teeth on a miter saw blade significantly affects its cutting performance, particularly when working with materials such as metal or plastic.

- Fewer Teeth (24-40 Teeth): Blades with fewer teeth are generally better for cutting softer materials like plastic and wood.

- Medium Teeth (40-60 Teeth): A medium tooth count provides a balance between speed and finish, making it versatile for a range of materials.

- More Teeth (60+ Teeth): Blades with a high tooth count are ideal for producing smooth finishes, especially on harder materials like metal.

- Tooth Geometry: The shape and angle of the teeth also play a crucial role in cutting efficiency and finish quality.

- Material of the Blade: The type of material used in the blade can influence its cutting capability and durability based on the tooth count.

Fewer teeth, typically ranging from 24 to 40, allow for quicker cuts and are less likely to clog when cutting softer materials such as plastic or wood. These blades remove material more aggressively, making them suitable for rough cuts but resulting in a rougher finish.

Medium tooth counts, ranging from 40 to 60, provide a good compromise between speed and finish quality. They are effective for a variety of materials, making them a popular choice for general-purpose cutting.

Blades with more than 60 teeth are designed for fine cuts, especially in harder materials like metal and dense plastics. The increased number of teeth allows for a smoother finish as they remove less material with each pass, reducing chipping and splintering.

The geometry of the teeth, such as their shape and cutting angle, significantly affects the performance of the blade. For instance, alternate top bevel (ATB) teeth are great for cross-cutting, while flat-top grind (FTG) teeth are more suited for ripping.

Lastly, the material of the blade, such as carbide or high-speed steel, can also affect performance. A blade made of high-quality materials with the right tooth count will last longer and provide better cutting outcomes across various materials.

What Factors Should You Consider When Choosing the Right Number of Teeth for Your Miter Saw Blade?

When selecting the best number of teeth on a miter saw blade, several factors must be taken into account to ensure optimal performance and results.

- Material Type: The type of material you are cutting significantly influences the number of teeth needed on your miter saw blade.

- Cutting Speed: The number of teeth affects the speed at which you can make cuts, impacting efficiency and finish quality.

- Desired Finish: The quality of the cut is directly related to the tooth count; more teeth can yield a smoother finish.

- Blade Diameter: The size of the blade also plays a critical role in determining the ideal number of teeth for effective cutting.

- Cutting Thickness: The thickness of the material being cut can dictate the appropriate tooth count for achieving clean cuts.

Material Type: Different materials such as wood, metal, or plastic require different blade specifications. For instance, a blade designed for cutting hardwoods typically has more teeth than one meant for softwoods, as the latter can tolerate a coarser cut.

Cutting Speed: Blades with fewer teeth can cut faster but may produce a rougher edge, while blades with more teeth provide a slower cut but result in a finer finish. Choosing the right balance can enhance productivity without compromising on quality.

Desired Finish: If the goal is to achieve a smooth, finished edge, opting for a blade with a higher tooth count, such as 60 or 80 teeth, is advisable. Conversely, for rough cuts where finish quality is less of a concern, a blade with fewer teeth, like 24 or 40, may suffice.

Blade Diameter: The diameter of the miter saw blade affects how the teeth engage with the material, and larger blades often have more teeth than smaller ones. Therefore, understanding the relationship between blade size and tooth count is crucial for achieving optimal cutting performance.

Cutting Thickness: Thicker materials generally benefit from blades with fewer teeth, as they can remove material more efficiently. However, for thinner materials, a higher tooth count can ensure precision and reduce the risk of splintering.

How Do Blade Material and Design Influence the Ideal Tooth Count?

The ideal number of teeth on a miter saw blade is influenced by both the blade material and its design, which determine cutting efficiency and finish quality.

- Blade Material: The material of a miter saw blade affects its durability and cutting performance.

- Tooth Design: The shape and angle of the teeth play a crucial role in how the blade interacts with the material being cut.

- Tooth Count: The number of teeth on a blade impacts the smoothness of the cut and the speed of the operation.

- Application-Specific Needs: Different materials and cutting applications require specific tooth counts to achieve the best results.

Blade Material: Miter saw blades can be made from various materials, including high-speed steel (HSS), carbide-tipped, and diamond blades. Carbide-tipped blades are popular due to their durability and ability to maintain sharpness longer than HSS blades, making them suitable for cutting harder materials without frequent replacements.

Tooth Design: The design of the teeth, including their shape and angle, determines how efficiently the blade cuts through wood or other materials. For instance, flat-top grind (FTG) teeth are ideal for ripping, while alternate top bevel (ATB) teeth provide a cleaner finish for cross-cutting applications.

Tooth Count: A higher tooth count generally results in a smoother cut, making it ideal for finish work, while a lower tooth count allows for faster cuts through thicker materials. For example, a blade with 60 teeth is excellent for fine woodworking, whereas a blade with 24 teeth is better suited for rough cuts.

Application-Specific Needs: The best number of teeth on a miter saw blade can vary based on the type of material being cut and the desired finish. For instance, when cutting softwoods, a blade with fewer teeth can provide faster cuts, while cutting hardwoods might require a blade with a higher tooth count for a smoother result.

What Role Does Cutting Speed Play in Tooth Count Selection?

The cutting speed significantly influences the selection of the best number of teeth on a miter saw blade.

- Higher Cutting Speed: At increased cutting speeds, a blade with fewer teeth is often preferred, as it reduces the friction and heat generated during the cut.

- Lower Cutting Speed: For slower cutting speeds, a blade with more teeth is advantageous, ensuring a smoother finish and better control over the cut.

- Material Type: The type of material being cut also affects tooth count selection; harder materials may require fewer teeth to prevent binding.

- Cutting Depth: The depth of the cut can influence the ideal tooth count; deeper cuts might benefit from more teeth to maintain stability and accuracy.

- Blade Design: The design and geometry of the blade, including tooth shape and angle, can impact how cutting speed relates to tooth count effectiveness.

Higher cutting speeds typically require fewer teeth on the blade to minimize friction and heat, which can otherwise damage both the blade and the workpiece. This setup allows for faster material removal without compromising the integrity of the cut.

In contrast, lower cutting speeds benefit from a higher tooth count, as this configuration can create a finer, smoother finish by allowing for more cutting edges to engage with the material. This also helps to provide better control, reducing the risk of tear-out or splintering.

The material type being cut is also crucial in determining tooth count; harder materials like hardwoods may necessitate a blade with fewer teeth to avoid binding and overheating, while softer materials can be effectively managed with more teeth. Understanding the material’s properties allows for optimizing the tooth count for both speed and finish quality.

The depth of the cut is another factor to consider; deeper cuts often require more teeth to ensure stability and reduce vibration, which can lead to inaccuracies. A blade with more teeth engages more of the material at once, improving control during deeper cuts.

Lastly, the design and geometry of the blade play a significant role in the interaction between cutting speed and tooth count. Different tooth shapes and angles can change how effectively a blade performs at various speeds, making it essential to match the blade design with the intended cutting conditions for optimal results.

Related Post: