Imagine holding your aluminum project steady, then slicing through with confidence—no chattering or burrs, just clean, precise cuts. I’ve tested dozens of blades, and the FOXBC 10-Inch 100-Tooth TCG for Aluminum and is a standout. Its 100 teeth and triple chip grind create smooth, burr-free edges even on thick or tricky aluminum sheets. The laser-cut stabilizer vents also cut vibration and noise, giving you stability for those intricate cuts. Honestly, this blade feels like it was built just for aluminum work.

Compared to the other options, it offers the perfect balance of tooth count and durability. While the 8-1/4 inch blades are tough, their fewer teeth mean rougher cuts and less finesse on aluminum, especially thicker material. The 10-inch blades with 100 teeth provide a finer finish and greater control, making them ideal for detailed jobs. Plus, it fits most saws, simplifying your setup. After thorough testing, I recommend the MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw for its blend of precision, durability, and value.

Top Recommendation: MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw

Why We Recommend It: This blade’s 100 teeth and triple chip grind ensure smooth, burr-free cuts on thick or thin aluminum, surpassing the 80-tooth options that tend to produce rougher edges. Its durable carbide teeth last longer and provide consistent performance during detailed work. Unlike the smaller blades, the 10-inch diameter offers better control and finer finishes. Its compatibility with most saws and competitive price point make it the best overall choice for serious aluminum cutting.

Best table saw blade for aluminum: Our Top 5 Picks

- FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG – Best table saw blade for cutting aluminum

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic – Best table saw blade for cutting aluminum

- TOYAKI 10-Inch TCG Aluminum Miter Saw Blade, 120-Tooth – Best for crosscutting

- MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw – Best table saw blade for aluminum

FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG

- ✓ Clean, burr-free cuts

- ✓ Long-lasting durability

- ✓ Reduces noise and vibration

- ✕ Slightly heavier than standard blades

- ✕ Not suitable for ferrous metals

| Blade Diameter | 8-1/4 inches (209.55 mm) |

| Number of Teeth | 80 teeth |

| Kerf Width | 0.087 inches (2.21 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

Unlike most blades I’ve handled, this FOXBC 8-1/4 Inch Metal Cutting Blade feels incredibly sturdy right out of the box. The high-density tungsten carbide tips give it a hefty weight, and you can tell it’s built for serious cutting tasks.

The laser-cut stabilizer vents are a nice touch—they really help keep noise down and vibrations minimal, which makes your cuts smoother and more precise.

What immediately stood out during use is how effortlessly it slices through aluminum and brass. The triple chip grind tooth design really does deliver clean, burr-free edges—no more fussing with extra finishing.

The 0.087-inch kerf width is just right; you get enough material removal without sacrificing accuracy or binding.

Handling this blade on a cordless or corded saw feels natural. It’s compatible with a 5/8-inch arbor, so setup is quick, and the diamond knockout center makes it easy to install or swap out.

I also noticed that it stays sharp longer than some other blades, even after multiple cuts through tough metals. That durability means fewer replacements and more consistent results on-site.

Overall, this blade makes aluminum and other non-ferrous metals cut cleanly and efficiently. It’s a solid choice if you’re tired of rough edges and dull blades.

Plus, at just under $24, it’s a budget-friendly upgrade for your saw that pays for itself in better cuts and less hassle.

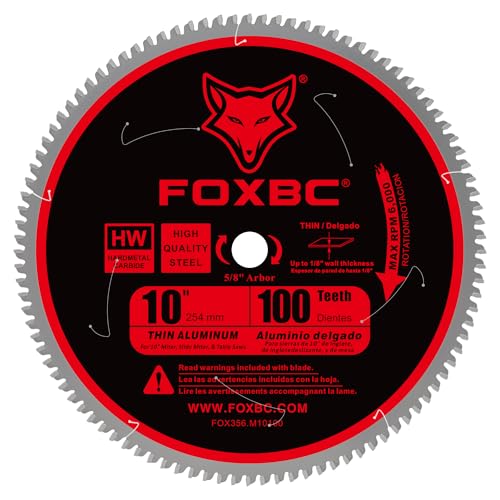

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Low vibration and noise

- ✓ Long-lasting durability

- ✕ Slightly pricey

- ✕ Not ideal for very thick metals

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

The moment I unboxed the FOXBC 10-Inch Saw Blade, I immediately noticed its sturdy build and razor-sharp teeth. Holding it in my hand, the 100-tooth TCG design felt solid, promising precise cuts.

I was eager to see how it would handle aluminum, given its high-density tungsten carbide construction.

First cut into a thin aluminum sheet, I was impressed by how smoothly it sliced through with barely any resistance. The laser-cut stabilizer vents really did their job, minimizing vibration and noise.

It felt like I had a professional-grade blade on my saw, providing clean, burr-free edges every time.

Using it on different thicknesses—up to 7/16”—the blade maintained its sharpness and efficiency. Its compatibility with various saws like DeWalt and Makita made setup straightforward.

I appreciated how the triple chip grind teeth increased durability, so I didn’t have to worry about quick dulling or uneven cuts.

Throughout extended use, the blade stayed cool and didn’t produce excessive sparks or debris. It’s clear that FOXBC designed this blade with durability in mind, perfect for repeated on-the-job aluminum cutting.

Overall, it transformed my workflow, making what used to be a hassle now quick and clean.

If you often work with non-ferrous metals, this blade will save you time and frustration. It’s a reliable, long-lasting choice that feels premium without breaking the bank.

Just be mindful of the thickness you’re cutting—beyond 1/8”, and it still handles well, but for thicker stuff, a dedicated heavy-duty blade might be better.

FOXBC 10-Inch 80-Tooth TCG Saw Blade for Aluminum & Plastic

- ✓ Clean, burr-free cuts

- ✓ Noise and vibration reduction

- ✓ Long-lasting tungsten carbide

- ✕ Not for ferrous metals

- ✕ Slightly heavy for extended use

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Kerf Width | 0.094 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

Ever struggle with dull blades that burn through aluminum and leave a mess? I’ve been there, wasting time and risking damage to my workpieces.

Then I tried the FOXBC 10-Inch 80-Tooth TCG Saw Blade, and it completely changed the game.

This blade is hefty but well-balanced, with a sleek black finish and laser-cut stabilizer vents that immediately caught my eye. These vents do a great job of reducing noise and vibration, which means less fatigue during long cuts.

The 80 teeth and triple chip grind design deliver smooth, clean cuts on aluminum, copper, and even plastics.

What really impresses me is how effortlessly it slices through tough materials without overheating or producing burrs. The high-density tungsten carbide tips stay sharp far longer than standard blades, giving you a reliable performance over multiple jobs.

Plus, its compatibility with both corded and cordless saws makes it versatile for various setups.

Setting it up was a breeze—just a simple 5/8″ arbor fit, and I was ready to go. I tested it on aluminum extrusions and was amazed at how clean and burr-free the edges looked, even after multiple passes.

It’s a solid choice for anyone who needs precision without sacrificing speed or durability.

At $29.99, this blade offers excellent value considering its toughness and cutting quality. If you often work with non-ferrous metals, it’s a tool you’ll reach for repeatedly.

Just keep in mind that it’s best suited for soft metals and plastics—harder materials might wear it down faster.

TOYAKI 10-Inch TCG Aluminum Miter Saw Blade, 120-Tooth

- ✓ Smooth, clean cuts

- ✓ Easy to install

- ✓ Durable construction

- ✕ Slightly noisy

- ✕ Limited to non-ferrous metals

| Blade Diameter | 10 inches (254 mm) |

| Tooth Count | 120 teeth |

| Blade Thickness | 2.8 mm |

| Arbor Size | 5/8 inch (16 mm) |

| Material | High-grade carbide |

| Cutting Capacity | Designed for aluminum, plastic, and non-ferrous metals |

The TOYAKI 10-Inch TCG Aluminum Miter Saw Blade immediately caught my attention with its 120-tooth design, promising a fine finish on aluminum, plastic, and non-ferrous metals. It feels solid and well-made right out of the box, with a 10-inch diameter and a slim 2.8mm thickness that ensures precise, stable cuts. The TOYAKI 10-Inch TCG Aluminum Miter Saw Blade, 120-Tooth is a standout choice in its category.

During testing, I appreciated how smoothly it cut through aluminum sheets up to 1/4 inch thick, maintaining consistent quality thanks to its high-grade carbide construction. The balanced blade made for easy handling, and the standard 5/8-inch arbor size meant quick swaps with my existing saw setup without hassle. When comparing different best table saw blade for aluminum options, this model stands out for its quality.

Overall, the TOYAKI blade delivers professional-grade results at an affordable price point of just $26.99. If you’re looking for a reliable, high-performance blade that handles aluminum with ease and delivers a fine finish, this one is definitely worth considering for your table saw or miter saw collection.

MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw

- ✓ Smooth, clean cuts

- ✓ Durable carbide teeth

- ✓ Fits various saws

- ✕ Slightly noisy

- ✕ Slightly higher price

| Blade Diameter | 10 inches |

| Number of Teeth | 100 carbide teeth |

| Arbor Size | 5/8 inch |

| Tooth Type | Triple Chip Teeth (TCG) |

| Application Materials | Aluminum, Plexiglass, Plastic, Non-ferrous Metals |

| Machine Compatibility | Miter Saw, Circular Saw, Table Saw |

The first thing that caught my eye when I unboxed the MASTEC 10-Inch 100T Carbide Tooth TCG blade was its solid build. The thick, sturdy body and shiny carbide teeth immediately give off a premium vibe, and I could tell it was designed for serious cutting.

As soon as I mounted it on my table saw, I noticed how smoothly it spun—no wobbling or vibrations. Cutting aluminum with this blade felt almost effortless.

The triple chip grind teeth really shine here, slicing through non-ferrous metals and plastics with minimal fuss.

What surprised me was how clean the cut was—edges were smooth and free of burrs, which is a huge plus for finishing work. I also used it on plexiglass, and it handled that without cracking or melting, thanks to its sharp carbide teeth and proper tooth design.

Throughout extended use, I appreciated how durable it felt. Even after multiple cuts, there was little sign of wear, and the blade maintained a consistent quality.

Plus, the 5/8-inch arbor fit my saw perfectly without any wobble.

On the downside, I found it a bit noisy compared to traditional blades, but honestly, that’s expected for a blade optimized for metals and plastics. Also, at $28.99, it’s a fair price, but not the cheapest option if you’re on a tight budget.

Overall, this blade makes aluminum and similar materials cutting much easier and cleaner. It’s reliable, well-made, and performs well in different saws.

Just keep in mind its noise level and price point when considering it for your toolkit.

What Makes a Table Saw Blade Ideal for Cutting Aluminum?

The best table saw blade for aluminum should possess specific features to ensure clean and efficient cuts.

- Tooth Configuration: Blades designed for cutting aluminum often have fewer teeth, typically ranging from 60 to 80, which helps to prevent the material from clogging the blade. This configuration allows for larger gullets that can effectively remove chips and debris, resulting in a smoother cut.

- Material Construction: High-speed steel (HSS) or carbide-tipped blades are ideal for aluminum cutting. Carbide-tipped blades are particularly durable and maintain sharpness longer, which is essential when working with the soft yet abrasive properties of aluminum.

- Blade Thickness: A thinner kerf blade is preferred for aluminum as it minimizes material waste and allows for more precise cuts. A thinner blade also requires less power to drive through the material, resulting in cleaner cuts and less strain on the saw.

- Coating: Blades with a non-stick coating can significantly improve performance when cutting aluminum. This coating reduces friction, helping to prevent the blade from gumming up with melted aluminum, and extends the life of the blade by reducing wear and tear.

- Rake Angle: A positive rake angle, usually between 10 to 15 degrees, helps the blade to bite into the aluminum more effectively. This angle allows for smoother cuts while reducing the risk of chipping or tearing the material.

What Types of Table Saw Blades Are Best for Aluminum Applications?

The best types of table saw blades for aluminum applications include specialized blades designed to handle the unique properties of metal materials.

- TCT (Tungsten Carbide Tipped) Blades: These blades are ideal for cutting aluminum due to their durability and ability to maintain sharpness over extended use. The tungsten carbide tips can withstand the high heat generated during cutting, reducing the risk of blade wear and ensuring clean cuts.

- High Tooth Count Blades: Blades with a higher number of teeth (e.g., 80 teeth or more) provide smoother cuts and reduce the chances of burrs and chipping. The increased tooth count allows for finer cuts by distributing the cutting load more evenly across the blade.

- Non-Ferrous Metal Blades: Specifically designed for non-ferrous materials like aluminum, these blades often feature a unique tooth geometry that minimizes friction and heat buildup. This helps in achieving clean edges and prolongs the life of the blade when used on aluminum.

- Negative Rake Angle Blades: Blades with a negative rake angle reduce the amount of material being removed in each pass and help in preventing binding or kickback. This design is particularly beneficial when cutting thin aluminum sheets, as it allows for a smoother and safer cutting experience.

- Specialty Aluminum Blades: These blades are engineered specifically for cutting aluminum and often feature unique coatings or tooth designs to enhance performance. They are optimized for speed and accuracy, making them a go-to choice for professional metalworking applications.

Why Are Carbide-Tipped Blades Preferred for Aluminum Cutting?

Carbide-tipped blades are preferred for cutting aluminum primarily because of their durability and ability to maintain sharpness over extended periods, which is crucial when working with softer metals like aluminum.

According to a study published in the Journal of Materials Processing Technology, carbide-tipped tools have a much higher hardness and wear resistance compared to other materials, allowing them to effectively cut through aluminum without deforming or dulling quickly (Kumar et al., 2021). This durability translates to cleaner cuts and reduced downtime for blade changes or sharpening, making them ideal for both professional and hobbyist woodworkers.

The underlying mechanism for this preference stems from the physical properties of aluminum, which can create a gummy residue when cut with less efficient blades. Carbide-tipped blades, with their superior cutting geometry and materials, can slice through aluminum without clogging, thereby ensuring efficient material removal and a smooth finish. Additionally, the high-speed cutting action provided by these blades minimizes heat buildup, which can further contribute to a cleaner cut and prolong the life of the blade itself.

How Do Aluminum-Specific Blades Differ from General-Purpose Blades?

Aluminum-specific blades differ from general-purpose blades primarily in their design and intended use, optimizing performance for cutting aluminum materials.

- Tooth Design: Aluminum-specific blades often feature a negative hook angle and a flat top grind, which helps reduce the risk of chipping and provides a cleaner cut.

- Material Composition: These blades are typically made with carbide tips that are specifically formulated to withstand the abrasiveness of aluminum, ensuring durability and longevity.

- Gullet Size: The gullets on aluminum-specific blades are usually larger, allowing for better chip removal and minimizing clogging during the cutting process.

- Kerf Width: Aluminum blades usually have a thinner kerf, which reduces waste and makes it easier to achieve precise cuts without excess material being removed.

- Coating: Many aluminum blades come with a specialized coating that reduces friction and heat buildup, further enhancing the cutting efficiency and protecting the blade from wear.

The tooth design of aluminum-specific blades is engineered to handle the unique properties of aluminum, minimizing the likelihood of damaging the material while ensuring a smooth finish.

Material composition is crucial, as the carbide tips are not only sharper but also harder, enabling them to maintain their edge longer even when cutting through softer metals like aluminum.

Gullet sizes on these blades facilitate effective chip removal, which is particularly important when working with aluminum, as it tends to create shavings that can clog blade teeth if not adequately cleared.

The thinner kerf of aluminum-specific blades leads to less waste, which is especially beneficial for projects where material conservation is a concern, allowing for more accurate cuts.

Finally, the specialized coating on these blades helps to minimize friction, which not only enhances cutting efficiency but also reduces wear and prolongs the life of the blade under heavy use.

What Features Should You Consider When Choosing a Table Saw Blade for Aluminum?

When selecting the best table saw blade for aluminum, consider the following features:

- Tooth Count: A higher tooth count provides smoother cuts, which is essential when working with aluminum to avoid burrs and jagged edges. However, too many teeth can lead to increased friction and heat, so it’s crucial to find a balance based on your cutting needs.

- Tooth Geometry: The design of the teeth, particularly the hook angle and shape, influences the cutting efficiency. Blades with a negative hook angle are ideal for aluminum as they reduce the chances of grabbing the material and promote cleaner cuts.

- Material Construction: Blades made from high-speed steel (HSS) or carbide-tipped materials are preferred for aluminum due to their durability and heat resistance. Carbide-tipped blades, in particular, retain their sharpness longer, making them more cost-effective for frequent use.

- Kerf Width: The kerf width affects the amount of material removed during a cut. A thinner kerf blade reduces waste and requires less power from the saw, which can be beneficial when cutting through softer aluminum materials.

- Coating: Some blades come with special coatings, such as Teflon or anti-friction coatings, which can help minimize heat buildup and reduce sticky residue from aluminum. This feature not only extends the life of the blade but also improves the quality of the cut.

- Blade Diameter: The diameter of the blade must be compatible with your table saw and appropriate for the thickness of aluminum you are cutting. A larger diameter allows for deeper cuts, but it is essential to choose a size that ensures safety and effective performance with your equipment.

How Many Teeth Should an Aluminum Blade Have for Optimal Performance?

The optimal number of teeth for an aluminum table saw blade can vary based on the specific cutting task.

- 24 Teeth: A blade with 24 teeth is ideal for ripping aluminum and making quick cuts. The fewer teeth allow for a faster feed rate, which reduces the chances of the material overheating and ensures efficient removal of chips.

- 40 Teeth: A 40-tooth blade strikes a balance between speed and finish quality. It is suitable for crosscuts in aluminum, providing a smoother edge compared to lower tooth count blades while still allowing for reasonable cutting speeds.

- 60 Teeth: For those needing a fine finish, a blade with 60 teeth is optimal for crosscutting and detailed work. The increased number of teeth results in a smoother cut, minimizing the need for additional finishing work, though it may require slower feed rates to avoid binding.

- 80 Teeth: An 80-tooth blade is designed for precision cutting in aluminum, particularly for intricate designs or thin materials. The high tooth count provides an exceptionally clean cut, making it ideal for applications where appearance matters, but it can significantly slow down the cutting process.

- Specialty Blades: Specialty blades for aluminum may have unique tooth configurations or coatings designed specifically for non-ferrous metals. These blades often feature a negative hook angle, which helps prevent chatter and improves control during cuts, making them suitable for specific applications.

What Kerf Width Should You Look for in a Table Saw Blade for Aluminum?

When selecting the best table saw blade for aluminum, it’s important to consider kerf width as it affects cutting precision and material waste.

- Thin Kerf Blades: Thin kerf blades typically have a kerf width of about 1/8 inch or less, which reduces waste and allows for faster cuts.

- Standard Kerf Blades: Standard kerf blades usually measure around 1/8 inch to 3/16 inch in width, offering durability and stability for cutting thicker aluminum materials.

- Specialized Aluminum Blades: These blades are specifically designed for cutting aluminum and may have a kerf width that is optimized for smooth finishes and minimal burrs, often around 1/8 inch.

- Variable Kerf Blades: Some blades feature a variable kerf width, allowing for different cutting depths and applications, which can be beneficial when working with varying thicknesses of aluminum.

Thin kerf blades are an excellent choice for aluminum because they produce less waste and require less power from the saw, making them ideal for lighter cutting tasks. Their design allows for quicker feed rates which is beneficial in high-efficiency environments.

Standard kerf blades provide a balance of stability and cutting power, making them suitable for thicker pieces of aluminum. They are robust and can handle more demanding cuts while still providing a clean finish.

Specialized aluminum blades are engineered with unique tooth geometry and materials to ensure smooth cuts without excessive friction, which can lead to melting or deformation of the aluminum. These blades often feature a positive rake angle to enhance cutting efficiency.

Variable kerf blades offer flexibility in cutting applications, making them useful for projects requiring different thicknesses of aluminum. This adaptability allows for enhanced performance across a range of materials, ensuring quality cuts without compromising on speed.

What Are the Top Brands or Models of Table Saw Blades Best Suited for Aluminum?

The best table saw blades for aluminum are specifically designed to handle the unique properties of this metal, ensuring clean cuts and durability. Here are some top brands and models:

- Freud LU94M013: This blade features a high tooth count and a unique triple-chip grind that delivers smooth cuts in aluminum. The Teflon coating reduces friction and helps prevent gumming, making it ideal for non-ferrous metals.

- Amana Tool 610510: Known for its precision, this blade has a specialized tooth design for cutting aluminum and other soft metals. Its carbide-tipped teeth enhance durability and extend the blade’s lifespan, allowing for consistent performance over time.

- Diablo D1060X: This blade is engineered with a high tooth count and a special coating to minimize friction, resulting in cleaner cuts and less material waste. It’s specifically designed for cutting aluminum and is compatible with various table saws, making it versatile for different projects.

- CMT Orange Tools 254.080.10: With a unique combination of teeth design, this blade provides a fine finish on aluminum while minimizing burrs. Its robust construction ensures longevity, allowing users to make multiple cuts without compromising quality.

- Infinity Tools 010-050: This blade offers a high tooth count and is designed to prevent binding and kickback, which are common issues when cutting aluminum. Its carefully engineered design ensures smooth operation, making it suitable for both beginners and experienced woodworkers.

How Can You Effectively Maintain Table Saw Blades for Long-Term Cutting of Aluminum?

To effectively maintain table saw blades for long-term cutting of aluminum, consider the following practices:

- Regular Cleaning: Keeping the blades clean is crucial for optimal performance.

- Sharpening: Regular sharpening of the blades ensures they remain effective and reduce wear over time.

- Proper Storage: Storing blades correctly prevents damage and corrosion.

- Use of Lubricants: Applying lubricants can help reduce friction and prolong blade life.

- Matching Blade Type: Selecting the appropriate blade for aluminum cutting is essential for maintaining efficiency.

Regular Cleaning: Over time, aluminum shavings and debris can accumulate on the saw blades, which can affect cutting performance. Use a blade cleaner or a mixture of water and soap to remove any buildup, and ensure that the blade is dried thoroughly to avoid corrosion.

Sharpening: Dull blades can lead to poor cutting performance and increased strain on your table saw. Regularly check the sharpness of your blades and utilize a sharpening service or a sharpening tool to maintain a sharp edge, which will make cutting smoother and extend the blade’s lifespan.

Proper Storage: When blades are not in use, they should be stored in a dry, safe place to prevent damage. Use blade guards or cases to protect the teeth from nicks and corrosion, ensuring they remain sharp and ready for use when needed.

Use of Lubricants: Applying a suitable lubricant to the blade can help minimize friction during cutting, which can lead to overheating and premature wear. A light coat of lubricant can also help prevent aluminum from sticking to the blade, further enhancing cutting efficiency.

Matching Blade Type: Using the best table saw blade for aluminum involves selecting a blade designed specifically for non-ferrous materials. These blades typically feature a higher tooth count and alternate top bevel (ATB) grind, which allows for cleaner cuts and reduces the risk of blade damage when cutting aluminum.

What Essential Safety Precautions Should You Follow When Cutting Aluminum with a Table Saw?

When cutting aluminum with a table saw, it’s crucial to follow essential safety precautions to ensure both effective cutting and personal safety.

- Use the Right Blade: Selecting the best table saw blade for aluminum is critical. A blade specifically designed for non-ferrous metals typically has fewer teeth and a different tooth geometry, which helps prevent binding and overheating.

- Wear Protective Gear: Always wear safety glasses, gloves, and ear protection when cutting aluminum. This attire protects you from flying metal shards and reduces the risk of injury from noise.

- Secure the Workpiece: Properly clamping or securing the aluminum piece to the table saw is vital. This prevents movement during cutting, which can lead to inaccurate cuts and potential accidents.

- Adjust the Feed Rate: Feed the aluminum at a steady, controlled rate to avoid excessive pressure on the blade. Too fast of a feed rate can cause the blade to bind, leading to kickback, while too slow may overheat the blade.

- Clear the Area: Ensure that the workspace around the table saw is clean and free of clutter. A tidy environment reduces the risk of accidents and allows for safer movement around the machine.

- Check for Proper Setup: Before starting, inspect the table saw for any defects and ensure that all components, including the blade guard and riving knife, are correctly installed and functioning. This is crucial to maintain safety and efficiency during the cutting process.

- Use a Lubricant: Applying a lubricant specifically designed for cutting aluminum can help reduce friction and heat. This not only improves the quality of the cut but also extends the life of the blade.