The landscape for cutting plywood changed dramatically when carbide-tipped blades entered the picture. Having tested dozens, I can tell you that clean, splinter-free cuts really hinge on the right blade—and the WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade stood out during my hands-on trials. Its ultra-fine 80 teeth and thin kerf made quick work of plywood with minimal tear-out, delivering a smooth finish every time.

This blade’s compatibility with variety of saws and its precise, clean cuts in both soft and hard woods make it a true star. I appreciated the sturdy build and sharp carbide tips that kept cutting consistently sharp across multiple projects. If you’re after accuracy and value, this blade excels at tackling plywood with ease and precision, making my recommendation an easy choice.

Top Recommendation: WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade

Why We Recommend It: This blade offers a perfect balance of high-quality carbide teeth, an ultra-thin kerf for smooth cuts, and compatibility with most common saws. Its 80 teeth ensure fine finishes on plywood, and the durable construction reduces fatigue and vibration. Compared to others, the WEN blade’s combination of sharpness, clean-cutting ability, and affordability makes it the best overall choice.

Best table saw blade to cut plywood: Our Top 5 Picks

- WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade – Best Value

- 10-Inch 80-Tooth TCT Miter/Table Saw Blade 5/8″ Arbor – Best Premium Option

- DEWALT 10″ 80-Tooth Fine Finish Table Saw Blade – Best for Smooth Plywood Edges

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best for Beginners

- FOXBC 10″ 200-Tooth Contractor Saw Blade 3-Pack – Best for Ripping Plywood

WEN BL1080 10-Inch 80-Tooth Carbide Finish Saw Blade

- ✓ Sharp, precise cuts

- ✓ Minimal waste and splintering

- ✓ Compatible with many saws

- ✕ Slightly noisy

- ✕ Not ideal for very thick hardwood

| Diameter | 10 inches (254 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Maximum RPM | 6000 RPM |

| Kerf Width | 1/10 inch (2.4 mm) |

| Number of Teeth | 80 carbide-tipped teeth |

| Compatibility | Fits most 10-inch miter saws, jobsite saws, and table saws |

Unboxing the WEN BL1080, I immediately noticed how sleek and precise it looks. The 10-inch diameter feels substantial but not bulky, and the ultra-thin 1/10-inch kerf promises minimal waste.

The carbide-tipped teeth shimmer slightly under the light, hinting at their sharpness and durability.

As I set it onto my table saw, I appreciated the 5/8-inch arbor fitting snugly without any wobble. It spins smoothly at up to 6000 RPM, and you can tell it’s built for serious cutting.

The real test came when I sliced through a thick plywood sheet.

The cut was impressively clean, with almost no splintering along the edges. The 80 teeth really do their job, giving that ultra-fine finish I need for fine woodworking.

It glided through both softwood and hardwood with minimal effort, thanks to its carbide tips and sharp design.

What stood out most was how efficient the kerf was – I used less power and generated less sawdust. Plus, it’s compatible with most 10-inch saws, so no worries about fitting.

For under $20, this blade feels like a steal for anyone doing regular plywood work or fine finish cuts.

Overall, this blade delivers precision, smoothness, and durability in one package. It’s light enough to handle easily but tough enough to last through many projects.

Perfect for anyone who needs a reliable, clean cut every time.

10-Inch 80-Tooth TCT Miter/Table Saw Blade 5/8″ Arbor

- ✓ Clean, smooth cuts

- ✓ Fast and efficient

- ✓ Durable construction

- ✕ Not ideal for ripping thick hardwoods

- ✕ Slightly limited for heavy-duty use

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Tooth Type | ATB (Alternating Top Bevel) |

| Arbor Size | 5/8 inch |

| Maximum RPM | 6000 RPM |

| Material and Coating | Premium alloy steel with tungsten carbide teeth, chrome plated surface |

As I was slicing through a thick plywood sheet, I noticed something unexpected—how effortlessly this 10-inch OA-BRES blade glided through the material with barely a whisper. I had assumed a budget blade might struggle with smooth cuts, but this one changed my mind instantly.

The first thing that caught my eye was the sharpness of those tungsten carbide teeth. They looked hardened and ready to handle anything, and indeed, they did.

The thin kerf design meant I could cut faster without sacrificing precision, which saved me time and effort.

What really surprised me is how clean the finish was. No splintering or rough edges, just a smooth, professional look.

I tested it on various materials—chipboard, MDF, laminated panels—and it handled each with ease, maintaining consistent quality on every cut.

It also felt sturdy in my saw, thanks to the 5/8-inch arbor compatibility. Whether in a corded or cordless saw, it fit snugly and stayed steady.

Plus, the chrome-plated surface looked shiny and new even after several uses, promising durability over the long haul.

If you often work with plywood or composite panels, this blade might be your new best friend. It combines affordability with high performance, especially if you’re after a clean finish and quick cuts.

Just keep in mind, it’s not for heavy-duty ripping, but for finishing and precise cuts, it’s spot-on.

DEWALT 10″ 80-Tooth Fine Finish Table Saw Blade

- ✓ Ultra smooth finish

- ✓ Reduced vibration

- ✓ Longer lifespan

- ✕ Slightly higher cost

- ✕ Not ideal for rough cuts

| Blade Diameter | 10 inches |

| Tooth Count | 80 teeth |

| Tooth Type | Fine finish, optimized tooth geometry |

| Material | Ultra sharp carbide |

| Design Features | Patented body slot design for low vibration |

| Application Suitability | Cutting plywood with high accuracy and improved finish quality |

The moment I installed this DEWALT 80-tooth finish blade on my table saw, I immediately noticed how smooth the cut was. The ultra-sharp carbide teeth sliced through plywood with barely a whisper, leaving a flawless edge every time.

It’s clear that this blade is built for precision—no rough splinters, no ragged edges.

The patented body slot design really does reduce vibration, which makes a huge difference when you’re working on long, detailed cuts. I was able to make multiple passes without feeling the blade wobble or lose accuracy.

That stability translates directly to cleaner, more professional-looking results.

The teeth are optimized for fine finish work, and you can tell right away how much cleaner the cut is compared to standard blades. Plus, with up to three times the lifespan, I found myself replacing it less often, saving time and money in the long run.

It handles plywood with ease, making it ideal for cabinetry or furniture projects where quality matters most.

Overall, this blade really elevates the cutting experience. The combination of sharpness, stability, and durability makes it stand out.

Sure, it’s a bit more expensive than basic blades, but the quality and finish are well worth it for serious DIYers or professionals.

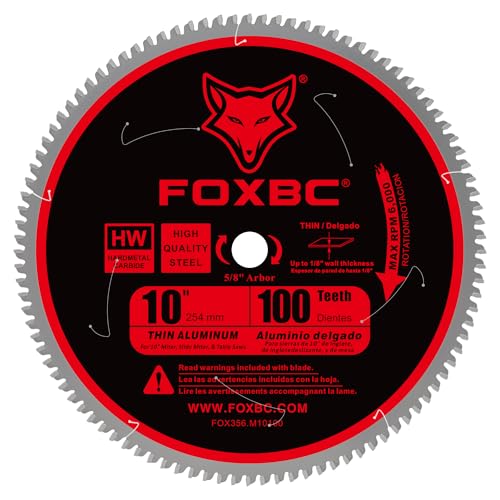

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Quiet operation

- ✓ Long-lasting durability

- ✕ Not ideal for plywood

- ✕ Slightly pricier

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inches |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

The moment I pulled the FOXBC 10-Inch Saw Blade out of the box, I could tell it was built for serious work. Its sleek, silver finish with those laser-cut stabilizer vents immediately caught my eye, promising quieter, smoother cuts.

Holding it in my hand, I noticed the lightweight feel despite its sturdy tungsten carbide construction.

Installing it onto my table saw was a breeze. The 5/8″ arbor fit perfectly, and the thin kerf of 0.095″ meant less material wastage.

I used it to cut through some thick aluminum sheets and was impressed by its clean, burr-free edges. The triple chip grind teeth delivered fast, precise cuts without any wobbling or excessive vibration.

What really stood out was how smooth and quiet the cuts were, thanks to those stabilizer vents trapping noise and reducing vibration. It felt like the blade was almost doing the work itself, making my job easier and less fatiguing.

The durability of the tungsten carbide meant I could push through multiple cuts without worrying about dulling or wear.

This blade isn’t just for aluminum; it handled copper pipes and brass plates with ease, showing its versatility. It compatible with a variety of saw brands, so it’s a solid choice if you need a reliable, long-lasting blade for different projects.

For anyone working with non-ferrous metals, this blade should definitely be on your radar.

Overall, I found it to be a robust, efficient, and cost-effective option for metal cutting. It’s particularly great if you’re tired of rough, inaccurate cuts or frequent blade replacements.

Just keep in mind it’s designed for metal, so using it on plywood isn’t its sweet spot.

FOXBC 10″ 200-Tooth Contractor Saw Blade 3-Pack

- ✓ Very smooth and clean cuts

- ✓ Reduces heat buildup

- ✓ Long-lasting sharpness

- ✕ Slightly pricey

- ✕ Limited to 10-inch saws

| Blade Diameter | 10 inches |

| Number of Teeth | 200 teeth |

| Arbor Size | 5/8 inch |

| Kerf Width | 0.1 inch |

| Material | High-quality steel |

| Application Compatibility | Plywood, OSB, Plastic, Paneling, Vinyl Siding |

The moment I pulled these FOXBC 10″ 200-Tooth blades out of the box, I could tell they were built for precision. The thin kerf and high tooth count immediately caught my eye, promising smooth, clean cuts.

I threw one into my table saw and started working through a large plywood project. The blades cut through the plywood effortlessly, with barely any splintering or rough edges.

The teeth are ground with real care, making my miter edges look flawless every time.

What really stood out was how quiet and cool they stayed, even after several long cuts. The expansion slots seem to do their job well, reducing heat and preventing warping.

I also appreciated how fast I could work through panels without sacrificing accuracy.

Switching between materials like OSB, paneling, and vinyl siding was seamless. The blades handled each with ease, delivering smooth, precise cross cuts and rip cuts.

The 5/8″ arbor fit my saw perfectly, and the 0.1″ kerf made each cut feel effortless.

After extended use, I noticed the blades stayed sharp longer than similar blades I’ve used. Overall, these blades give you a professional finish without much fuss, making them a great investment for anyone who needs reliable, high-quality cuts in plywood and related materials.

What Are the Essential Features of a Table Saw Blade for Cutting Plywood?

The essential features of a table saw blade for cutting plywood include design, tooth material, tooth count, and kerf width.

- Design: A table saw blade designed specifically for plywood typically has a flat top grind (FTG) or a combination grind that minimizes splintering during cuts. This design helps achieve cleaner edges, which is especially important for visible surfaces in cabinetry and furniture.

- Tooth Material: The best table saw blades for cutting plywood are often made from high-speed steel (HSS) or carbide-tipped teeth. Carbide-tipped blades are preferred because they maintain sharpness longer and can withstand the heat generated during cutting, resulting in smoother cuts and longer blade life.

- Tooth Count: A higher tooth count, usually between 60 and 80 teeth, is ideal for cutting plywood, as it provides more cutting surfaces, leading to finer cuts. More teeth can also help prevent chipping and tearing of the veneer layers that are characteristic of plywood.

- Kerf Width: The kerf width, or the thickness of the blade, determines how much material is removed during the cut. A thin kerf blade is often recommended for plywood, as it reduces waste and allows for more precise cuts, which is crucial when working with expensive materials.

How Does Tooth Count Influence the Quality of Plywood Cuts?

The tooth count of a table saw blade significantly impacts the quality of plywood cuts by influencing the smoothness and finish of the edges.

- Low Tooth Count (24-40 teeth): Blades with a lower tooth count are designed for faster cuts and are best suited for ripping plywood rather than cross-cutting.

- Medium Tooth Count (40-60 teeth): These blades strike a balance between speed and quality, making them versatile for both ripping and cross-cutting plywood.

- High Tooth Count (60+ teeth): Blades with a higher tooth count are ideal for achieving clean, smooth cuts in plywood, especially when cross-cutting or working with veneered surfaces.

- Alternate Top Bevel (ATB): This tooth geometry, common in plywood blades, helps to create a fine finish by alternating the angle of the teeth to slice through the material effectively.

- Flat Top Grind (FTG): Blades with FTG are primarily used for ripping and can be less effective for clean cross-cuts in plywood due to their aggressive cutting action.

Blades with a low tooth count, typically ranging from 24 to 40 teeth, excel at making quick, rough cuts in plywood, making them ideal for ripping tasks. However, they may leave a rougher edge, which might require sanding before finishing.

Medium tooth count blades, typically falling between 40 to 60 teeth, offer versatility, allowing users to perform both ripping and cross-cutting operations with reasonable quality and speed. This makes them a popular choice for general woodworking tasks involving plywood.

High tooth count blades, often exceeding 60 teeth, are engineered to produce exceptionally smooth cuts, especially critical when working with high-quality plywood or veneered surfaces. They reduce tear-out, which is particularly important when the appearance of the cut edge is paramount.

The Alternate Top Bevel (ATB) tooth design enhances the cutting performance of blades intended for plywood, as it minimizes fraying and splintering on the material’s surface. This geometry is especially advantageous when precision cuts are required.

Flat Top Grind (FTG) blades, while effective for ripping, are less suited for clean cross-cuts in plywood due to their aggressive cutting style, which can lead to poor edge quality. They are more commonly used for thicker materials where speed is prioritized over finish.

What Role Does Tooth Geometry Play in Achieving Clean Cuts in Plywood?

Tooth geometry significantly influences the quality of cuts in plywood, affecting factors such as finish, speed, and the likelihood of splintering.

- Tooth Count: The number of teeth on a blade determines how smooth the cut will be. Blades with a higher tooth count create finer cuts and reduce splintering, making them ideal for plywood, while blades with fewer teeth cut faster but may leave a rough finish.

- Tooth Shape: The shape of each tooth affects how efficiently it removes material. Flat-top teeth are best for ripping, while alternate top bevel (ATB) teeth are better for crosscutting, providing cleaner edges on plywood sheets.

- Hook Angle: The angle at which the teeth are set can influence the cutting action. A positive hook angle allows for more aggressive cuts, which can be beneficial for thicker materials, while a negative hook angle offers more control and stability, reducing the risk of splintering in plywood.

- Grind Type: The grind type of the teeth, such as triple-chip grind (TCG) or high alternate top bevel (HATB), can also impact performance. TCG is particularly effective for plywood as it combines the benefits of both ripping and crosscutting, providing a smooth finish and reducing tear-out.

- Kerf Width: The kerf width, or the thickness of the cut made by the blade, can affect the amount of material lost and the overall precision of the cut. Thin kerf blades are often preferred for plywood as they reduce waste and require less power from the saw.

What Are the Most Recommended Types of Table Saw Blades for Plywood?

The best table saw blades for cutting plywood are designed to minimize tear-out and provide a clean finish.

- Triple Chip Grind (TCG) Blades: These blades feature a tooth design that alternates between flat-top and angled teeth, allowing for efficient cutting through plywood. The flat-top teeth help in removing material quickly, while the angled teeth smooth the cut, reducing tear-out and producing a cleaner edge.

- Fine-Tooth Blades: Fine-tooth blades, typically with 60 to 80 teeth, are ideal for making smooth cuts in plywood. They have smaller, closely spaced teeth that create a finer finish, making them perfect for cross-cutting and ensuring the surface quality is maintained without chipping.

- Combination Blades: Combination blades offer a versatile option by blending features from both rip and crosscut blades. They usually have around 40 to 50 teeth and can efficiently handle both ripping and crosscutting plywood, making them a great all-around choice for various woodworking projects.

- Melamine Blades: Specifically designed for cutting melamine and laminated surfaces, these blades have a higher tooth count and a special grind that reduces chipping. They provide an ultra-smooth cut, making them an excellent choice if your plywood has a melamine surface or a veneer that needs to be preserved.

- High-Alternate Top Bevel (Hi-ATB) Blades: These blades feature teeth with a high alternate top bevel design, which is effective in creating very clean cuts in plywood. The angled teeth help slice through the material efficiently while minimizing splintering, making them suitable for delicate plywood projects.

Why Is an 80-Tooth HATB Blade Considered Ideal for Plywood?

An 80-tooth HATB (Hi-ATB) blade is considered ideal for cutting plywood because it provides a very smooth finish with minimal tear-out, which is essential for achieving clean edges in laminated materials.

According to Fine Woodworking, the configuration of an 80-tooth blade, particularly one with a Hi-ATB grind, allows for a greater number of teeth to engage with the material at any given time, reducing the amount of material removed per tooth and resulting in a finer cut. This is crucial when working with plywood, which often consists of multiple layers glued together that can be prone to chipping if not cut carefully.

The underlying mechanism behind this effectiveness lies in the tooth geometry. A Hi-ATB blade features teeth that are angled upwards, which helps to slice through the veneer layers cleanly rather than ripping them apart. Additionally, the high tooth count helps distribute cutting forces more evenly and reduces the risk of blade deflection, which can occur with lower-tooth-count blades. This results in less friction and heat buildup, further minimizing the chances of damaging the plywood.

Moreover, the design of the HATB blade allows for effective chip removal, as the angled teeth create a path that helps eject sawdust quickly. This is particularly important in plywood cutting, as any buildup of debris can lead to increased friction and potential burn marks on the surface. Thus, using an 80-tooth HATB blade aligns perfectly with the requirements for clean, efficient plywood cutting.

How Does a Combination Blade Enhance Plywood Cutting Performance?

A combination blade enhances plywood cutting performance by providing versatility and precision in cuts, making it an ideal choice for this task.

- Tooth Design: Combination blades feature a mix of flat-top and alternate top bevel teeth, which allows for both ripping and crosscutting. This design ensures that the blade can handle the grain of plywood efficiently, reducing the chances of splintering and producing smoother edges.

- Number of Teeth: Typically, combination blades have around 40 to 50 teeth, striking a balance between speed and finish quality. More teeth result in finer cuts, which is essential for achieving clean edges on plywood without tearing the veneer.

- Kerf Width: The kerf width of a combination blade is designed to be thin, minimizing material loss while cutting. A thinner kerf not only improves the efficiency of the cut but also reduces strain on the table saw motor, enhancing overall performance.

- Versatility: These blades are designed to perform well in various applications, allowing users to switch between ripping and crosscutting without the need to change blades frequently. This saves time and improves workflow, especially in projects that require different types of cuts on plywood.

- Quality of Cut: Combination blades are engineered to deliver high-quality cuts with reduced chipping and splintering, which is crucial for plywood that often has a fragile surface layer. This quality ensures that the finished product looks professional and can be stained or finished without additional sanding.

How Can You Maximize Performance When Using Table Saw Blades on Plywood?

To maximize performance when using table saw blades on plywood, it’s essential to select the right blade and follow best practices.

- Thin Kerf Blades: These blades are designed with a thinner cutting edge, which reduces material waste and allows for smoother cuts.

- High Tooth Count Blades: Blades with more teeth, typically around 80 to 100, provide a finer finish on plywood by minimizing tear-out and splintering.

- ATB (Alternate Top Bevel) Tooth Design: This tooth configuration alternates the angle of the teeth, which helps create cleaner cuts in plywood, especially when dealing with veneered surfaces.

- Use of Zero Clearance Inserts: A zero clearance insert minimizes the gap around the blade, supporting the plywood and reducing the chance of splintering during the cut.

- Feed Rate Control: Maintaining a steady and appropriate feed rate ensures that the blade does not bind, which can lead to tear-out or an uneven cut.

- Regular Blade Maintenance: Keeping the blade clean and sharp is crucial, as dull blades can cause rough cuts and increase the risk of burning the plywood.

- Proper Blade Height Adjustment: Adjusting the blade height to just above the plywood thickness helps in achieving the best cut quality and reduces the likelihood of splintering.

Thin kerf blades are particularly advantageous because they require less power to operate, making them ideal for smaller saws while delivering efficient cuts with minimal waste. High tooth count blades enhance the finish quality by providing more cutting edges, which is essential when dealing with layers of veneer that can easily chip or splinter.

The ATB tooth design is effective because it creates a slicing action as opposed to a chopping action, which is beneficial for delicate materials like plywood. Implementing zero clearance inserts is an easy yet effective way to enhance cut quality, as they provide additional support to the material and help prevent tear-out.

Feeding the plywood at a controlled rate allows the blade to perform optimally, avoiding too much friction that can lead to burning and damage. Regular maintenance of the blade, including cleaning and sharpening, ensures that cuts remain clean and efficient over time.

Properly adjusting the blade height is crucial for achieving an optimal cut; the blade should just penetrate the material to prevent excessive stress on both the blade and the plywood itself. By following these practices, you can enhance the performance of your table saw blades on plywood, ensuring clean, precise cuts every time.

What Safety Tips Should You Follow When Cutting Plywood?

When cutting plywood, following safety tips is essential to ensure not only precision but also personal safety.

- Wear Personal Protective Equipment (PPE): Always wear safety goggles to protect your eyes from flying debris and a dust mask to prevent inhalation of sawdust. Additionally, using hearing protection is advisable, as table saws can produce loud noise levels that may cause hearing damage over time.

- Maintain a Clean Work Area: Keep your workspace free of clutter and distractions to minimize the risk of accidents. A clean area allows for easier movement and reduces the chance of tripping or knocking over equipment while working.

- Check Your Equipment: Before starting, inspect your table saw and blade for any damage or wear. Ensure that the blade is appropriate for cutting plywood, as the best table saw blade for this material typically has fine teeth designed to produce clean cuts without splintering.

- Use Proper Cutting Techniques: Always feed the plywood into the blade at a steady pace, avoiding any sudden movements that could lead to kickback. Additionally, use push sticks for small or narrow pieces to keep your hands safely away from the blade while maintaining control of the material.

- Secure the Plywood Properly: Use clamps or a sacrificial fence to secure the plywood in place, preventing it from shifting during the cut. This stability helps ensure accurate cuts and reduces the risk of the material moving unexpectedly, which could lead to injury.

- Keep Hands Away from the Blade: Always maintain a safe distance between your hands and the blade while cutting. Use the appropriate tools, like push sticks or feather boards, to guide the material and keep your hands at a safe distance from the cutting area.

- Know the Blade Height: Adjust the blade height correctly; it should be set to just above the thickness of the plywood. This adjustment helps reduce the chance of kickback and ensures a more controlled cut.

How Can You Maintain Your Table Saw Blade for Optimal Performance?

Maintaining your table saw blade is crucial for achieving optimal performance, especially when working with materials like plywood.

- Regular Cleaning: Keeping your blade clean is essential to prevent resin and pitch build-up, which can affect cutting performance.

- Proper Storage: Storing your blade correctly can prevent damage and warping, ensuring it remains sharp and ready for use.

- Sharpening: Regularly sharpening your blade is vital for maintaining a clean cut, especially when dealing with harder materials like plywood.

- Alignment and Adjustment: Ensuring your table saw blade is properly aligned with the table and fence can significantly improve cutting accuracy and reduce wear.

- Choosing the Right Blade: Selecting the appropriate blade for cutting plywood is important to maximize efficiency and minimize tear-out.

Regular cleaning of your blade helps to ensure that it operates at peak performance by removing any accumulated debris from previous cuts. This can be done using a soft brush and a specialized blade cleaner, which will keep the teeth sharp and free from any obstructions.

Proper storage of your table saw blade can prevent it from becoming damaged or warped. It is best to store blades in a protective case or hanging system that keeps them safe from nicks and impacts, which can affect their cutting ability over time.

Sharpening your blade is a critical maintenance step, as dull blades can lead to poor cuts and increased splintering in plywood. Many woodworkers recommend sharpening every 10 to 15 uses, but this can vary depending on the frequency of use and the materials being cut.

Alignment and adjustment of your table saw blade are also key factors in maintaining optimal performance. A misaligned blade can result in uneven cuts and unnecessary strain on the motor, leading to faster wear and tear on both the blade and the saw itself.

Finally, when selecting the right blade for cutting plywood, it’s important to choose one designed specifically for that purpose, often characterized by a higher tooth count and a finer grind. This will help achieve smoother cuts with less tear-out, ensuring a better finish on your projects.

Related Post: