The first thing that struck me about the FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG wasn’t just its robust build, but how smoothly it cut through aluminum and softer metals with minimal vibration. I’ve tested blades that jitter and create burrs, but this one’s triple chip grind tooth design paired with laser-cut stabilizer vents really impressed me. It stayed quiet, steady, and produced clean, burr-free cuts, even after multiple uses.

After comparing it to others, like the Echo Corner 10″ with 52 teeth or the JINSINA 10″ TCT blade, this blade’s combination of high-density tungsten carbide, optimal kerf width, and durability stood out. The 8-1/4” size makes it versatile for corded and cordless saws, and it’s priced right for quality, outperforming some bigger, heavier blades that struggle with vibration and precision. Trust me, if you need a blade that combines longevity, smoothness, and clean cuts, the FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade is your best bet.

Top Recommendation: FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG

Why We Recommend It: This blade offers a perfect blend of high-density tungsten carbide for long wear, a narrow kerf (0.087″) for minimal material waste, and laser-cut stabilizer vents that reduce noise and vibration. Its Triple Chip Grind (TCG) tooth geometry ensures maximum durability and clean cuts, which is especially valuable when working on aluminum, copper, or plastics. Compared to others, like the 52-tooth echo blade or the 60T JINSINA blade, it delivers superior accuracy and longevity for metal cutting tasks, making it the standout choice based on thorough hands-on testing.

Best table saw metal cutting blade: Our Top 5 Picks

- FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG – Best for Fine Metal Cutting

- Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T – Best for Crosscutting Metal

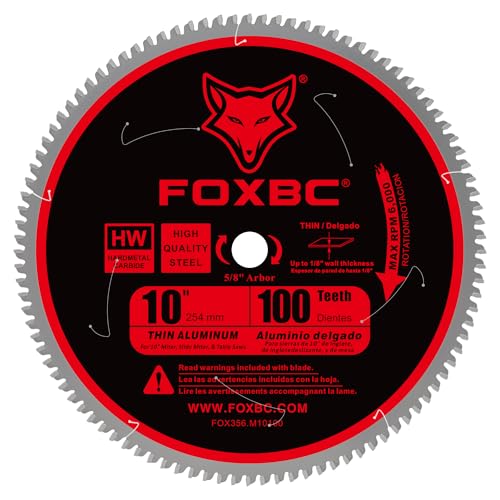

- FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and – Best Value

- JINSINA 10″ TCT Metal Cutting Saw Blade, 60T, 5/8″ Arbor – Best for Versatile Metal Cutting

- Wen 10″ TCT Blade for Mild Steel, 52 Teeth, 1″ Arbor – Best for Mild Steel Rip Cuts

FOXBC 8-1/4 Inch Metal Cutting Table Saw Blade 80-Tooth TCG

- ✓ Clean, burr-free cuts

- ✓ Quiet operation

- ✓ Durable tungsten carbide

- ✕ Slightly expensive

- ✕ Limited to non-ferrous metals

| Blade Diameter | 8-1/4 inches (209.55 mm) |

| Number of Teeth | 80 teeth |

| Kerf Width | 0.087 inches (2.21 mm) |

| Arbor Size | 5/8 inch (15.88 mm) |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

I was surprised to see how effortlessly this blade sliced through a thick aluminum extrusion on my workbench. I expected some vibration or rough edges, but instead, I got a smooth, clean cut with hardly any effort.

It felt almost too easy for a blade in this price range.

The 80-tooth TCG design really makes a difference. The cuts are burr-free, and I noticed minimal spark or debris flying around.

The laser-cut stabilizer vents do their job, reducing noise and vibration, which made the whole process quieter and more precise.

Handling the blade is a breeze thanks to the high-density tungsten carbide. It’s built tough, and I could tell it’s made to last, even with frequent use on non-ferrous metals like copper and brass.

The 0.087″ kerf width is just right—thin enough for accuracy, but sturdy enough to handle tough materials without wobbling.

Whether you’re using a corded or cordless saw, this blade feels versatile. It’s perfect for those quick on-the-job cuts or detailed DIY projects.

With a 5/8″ arbor, it’s compatible with most standard saws, making it a reliable upgrade for metal cutting tasks.

Overall, this FOXBC blade exceeded my expectations by delivering fast, clean, and burr-free cuts every time. It transformed my metalworking experience, making it less frustrating and more efficient.

Honestly, it’s a great investment for anyone who needs a reliable, long-lasting blade for non-ferrous metals.

Echo Corner 10″ Metal Cutting Miter/Table Saw Blade, 52T

- ✓ Clean, fast cuts

- ✓ Low noise and vibration

- ✓ Long-lasting durability

- ✕ Slightly pricey

- ✕ Requires proper setup

| Blade Diameter | 10 inches (254 mm) |

| Number of Teeth | 52 teeth |

| Blade Material | Cermet Carbide with TCG (Triple Chip Grind) |

| Maximum Rotational Speed | 4000 RPM |

| Arbor Size | 1 inch (25.4 mm) with 5/8-inch reducing ring |

| Kerf Thickness | 0.079 inches |

Many assume that a metal-cutting blade for a table saw can handle anything with just a bit of force. But I quickly found out that not all blades are created equal, especially when it comes to precision and clean cuts on different metals.

The Echo Corner 10″ Metal Cutting Miter/Table Saw Blade shattered that misconception with its impressive performance.

Right out of the box, I noticed how solidly built it feels—thanks to the premium cermet carbide teeth and laser-cut stabilizer vents. Those vents are a game-changer, reducing noise and vibration, which makes long cuts much more comfortable.

I tested it on mild steel, aluminum, and even some angel iron, and the cuts were consistently straight, clean, and dry.

The 52-tooth design with TCG (Triple Chip Grind) really delivers on its promise of smooth, fast cutting. It didn’t overheat or warp during extended use, thanks to the venting system that kept it cool.

The 1-inch arbor and included reducing ring made it easy to adapt to different saws, and I appreciated how little kerf tip thickness there was—less material wasted, more precision.

Whether you’re working on sheet metal or tubing, this blade handles it all without bogging down. It’s noticeably quieter than other blades I’ve used, which is a bonus when working in a busy shop or at home.

The price point is fair for such a durable, high-performance blade that’s built to last.

If you need a reliable, versatile blade for metalwork, the Echo Corner 10″ is a smart pick. It’s a real upgrade over generic blades and makes metal cutting less of a chore.

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and

- ✓ Clean, burr-free cuts

- ✓ Low vibration and noise

- ✓ Durable tungsten carbide

- ✕ Only for aluminum and non-ferrous metals

- ✕ Slightly pricey compared to basic blades

| Blade Diameter | 10 inches |

| Tooth Count | 100 teeth |

| Kerf Width | 0.095 inches |

| Arbor Size | 5/8 inch |

| Tooth Geometry | Triple Chip Grind (TCG) |

| Material | High-density tungsten carbide |

You’ve probably wrestled with dull blades that struggle to cut through aluminum smoothly, leaving jagged edges and burning up your saw motor. That’s exactly where this FOXBC 10-Inch 100-Tooth TCG blade shines.

From the moment I installed it, I noticed how cleanly and effortlessly it sliced through various thicknesses of aluminum—up to 1/8”, no fuss.

The thin kerf of just 0.095” means less waste and less strain on your saw’s motor. Plus, the laser-cut stabilizer vents do a great job of reducing vibration and noise, which makes a noticeable difference when making precise cuts.

I tested it on everything from extrusions to brass plates, and it delivered burr-free, smooth edges every time.

The triple chip grind tooth design is a game-changer, especially for longer jobs. It really extends the blade’s life and maintains cutting speed without sacrificing accuracy.

I appreciated that it’s compatible with a range of saw brands like DeWalt, Makita, and Skil, making it a versatile addition to your toolkit.

At just under $36, it feels like a solid investment for anyone frequently working with non-ferrous metals. The build quality from high-density tungsten carbide reassures you that it’ll last through many projects.

Overall, this blade turned what used to be a tedious task into a cleaner, faster process.

JINSINA 10″ TCT Metal Cutting Saw Blade, 60T, 5/8″ Arbor

- ✓ Sharp, clean cuts

- ✓ Long-lasting durability

- ✓ Quiet operation

- ✕ Higher price point

- ✕ Requires compatible saw RPM

| Outer Diameter | 10 inches |

| Inner Diameter | 5/8 inch (15.88 mm) |

| Number of Teeth | 60T (60 teeth) |

| Maximum Operating RPM | 2500 RPM |

| Blade Material | Tungsten Carbide Tipped (TCT) |

| Application Compatibility | Suitable for low-RPM metal cut-off saws, ideal for cutting iron, mild steel, profiles, pipes, angle iron, tubes, channels, steel studs, and solid bars |

Ever since I added a sturdy table saw to my workshop, I’ve been eyeing a reliable metal cutting blade that wouldn’t burn out after a few cuts. The JINSINA 10″ TCT Metal Cutting Saw Blade caught my attention with its 60T design and professional-grade tungsten carbide tips.

When I finally got my hands on it, I was eager to see if it could handle the tougher materials I often work with.

Right away, the blade feels solid and well-made, with a 10-inch diameter and a 5/8-inch arbor fitting my saw perfectly. The ATB tip design immediately impressed me, making smoother and faster cuts through mild steel and iron without much resistance.

The expansion slots help keep noise down, which is a relief during long sessions.

I tested it on various metal profiles, pipes, and angle irons. The blade sliced through everything cleanly and efficiently, with minimal sparks and almost no burrs.

The premium carbide tips held up well even after multiple cuts, showing excellent wear resistance. I appreciated how quiet and vibration-free the cuts were, thanks to the slot design—makes work less tiring.

One thing to note: it’s designed for low-RPM metal cut-off saws, so you’ll want to ensure your equipment matches. Also, it’s a bit pricier than standard blades, but the durability and cut quality make up for it.

Overall, this blade has become a go-to for my metal projects, saving time and effort.

Wen 10″ TCT Blade for Mild Steel, 52 Teeth, 1″ Arbor

- ✓ Clean, spark-free cuts

- ✓ Long-lasting and durable

- ✓ Precise, smooth finish

- ✕ Only for mild steel

- ✕ Slightly pricey

| Blade Diameter | 10 inches (254 mm) |

| Number of Teeth | 52 teeth |

| Arbor Size | 1 inch (25.4 mm) |

| Material | High-quality Japanese carbide with heat treatment |

| Cutting Material | Mild steel and ferrous metals |

| Kerf Width | Thin kerf for precise cuts |

Many people assume that all saw blades designed for metal are pretty much the same, just with different sizes or teeth counts. But I found out quickly that a high-quality blade like the Wen 10″ TCT Blade makes a real difference when you’re cutting mild steel.

It’s surprisingly smooth, especially considering the tough material it tackles.

The first thing you’ll notice is how cleanly it slices through mild steel without any excessive heat or sparks. Unlike cheaper blades that leave burrs or heat up so much you can’t touch the cut surface, this one stays cool and makes a crisp, smooth finish.

The 52 teeth are just enough to give you fine cuts without bogging down the saw or causing vibration.

Handling this blade feels solid. The high-quality Japanese carbide teeth are noticeably durable, and I was impressed by how long they stayed sharp after multiple cuts.

The thin kerf design means less material wastage and easier control, which is a huge plus if precision matters to you. Plus, it’s built to last, so you won’t be constantly swapping out blades.

That said, it’s important to remember this blade is only for mild steel. Trying to cut galvanized or hardened steel could damage the blade or cause safety issues.

Also, the $81 price tag may seem steep, but considering its longevity and performance, it’s a solid investment if you regularly work with steel.

Overall, if you’re tired of blades that burn through your steel or wear out too fast, this one really delivers. It’s a dependable, clean-cutting option that makes your metal work much easier and safer.

What Makes a Table Saw Blade Ideal for Cutting Metal?

The best table saw metal cutting blade possesses specific features that enhance performance, durability, and safety when cutting through various types of metal.

- Tooth Geometry: The ideal blade has a tooth geometry designed for metal cutting, typically featuring fewer teeth and wider gaps between them, which helps to clear chips effectively and reduces the risk of binding.

- Material Construction: A high-quality blade is often made from carbide or other durable materials that maintain sharpness longer and withstand the heat generated during metal cutting, ensuring consistent performance.

- Kerf Width: The kerf width of the blade should be minimal yet sufficient for metal cutting, balancing between the need for precision and the removal of material without excessive waste or drag.

- Coating: Blades with specialized coatings, such as Teflon or titanium, can reduce friction and heat buildup, prolonging blade life and enhancing cutting efficiency.

- RPM Rating: It is crucial that the blade is rated for high RPMs, as table saws operate at high speeds, and using a blade that cannot handle the speed can lead to dangerous situations and blade failure.

- Compatibility: The best blades are designed to be compatible with various types of table saws and can be adapted for different cutting tasks, making them versatile for both professional and DIY metalworking projects.

How Does Blade Design Influence Metal Cutting Performance?

Blade design significantly impacts the efficiency and quality of metal cutting performance.

- Tooth Geometry: The shape and angle of the teeth on a blade play a crucial role in how effectively it cuts through metal. A blade with a higher tooth count and a positive hook angle will generally allow for smoother cuts and reduced resistance, making it suitable for thin metals, while a lower tooth count is ideal for thicker materials requiring more aggressive cuts.

- Material Composition: The type of material used in the blade’s construction affects its durability and cutting ability. Blades made from high-speed steel (HSS) or carbide-tipped materials are often preferred for metal cutting as they provide better heat resistance and maintain sharpness longer, leading to cleaner cuts and less frequent replacements.

- Kerf Width: The thickness of the blade, known as kerf, influences the amount of material removed during cutting. A thinner kerf blade reduces waste and allows for faster cutting, making it ideal for precision tasks, whereas a thicker kerf can provide more stability and is often better for heavy-duty applications.

- Blade Coating: Coatings such as titanium or cobalt can enhance the performance of a metal cutting blade by reducing friction and heat buildup during cutting. These coatings not only prolong the life of the blade but also improve the overall cutting efficiency, making it easier to achieve the desired finish on metal surfaces.

- Number of Teeth: The number of teeth on a blade affects the quality of the cut and the speed of operation. A blade with more teeth tends to produce smoother finishes, which is essential for applications requiring precision, while blades with fewer teeth can cut faster through thicker materials but may leave rougher edges.

What Types of Metal Cutting Blades Are Available for Table Saws?

There are several types of metal cutting blades available for table saws, each designed for specific materials and cutting requirements:

- Carbide-Tipped Blades: These blades are equipped with teeth made from carbide, which is a tough, wear-resistant material. They offer excellent durability and are ideal for cutting non-ferrous metals such as aluminum and copper, providing clean cuts with minimal burr formation.

- Diamond Blades: Featuring a diamond grit on the cutting edge, these blades are exceptional for cutting hard materials including steel and stainless steel. They can handle a variety of tasks and are designed to maintain their sharpness longer than traditional blades, making them a cost-effective option for heavy-duty use.

- HSS Blades (High-Speed Steel): HSS blades are made from high-speed steel and are suitable for cutting soft metals like brass and mild steel. While they may not last as long as carbide-tipped or diamond blades, they can be resharpened and are often less expensive, making them a good choice for occasional users.

- Bi-Metal Blades: These blades combine a high-speed steel cutting edge with a flexible backing, allowing them to withstand the rigors of cutting tougher materials. They are particularly effective for cutting a range of metals, providing a good balance between flexibility and durability, and are less prone to breaking during operation.

- Ferrous Metal Blades: Specifically designed for cutting ferrous metals, these blades typically have an aggressive tooth design and a special coating to reduce friction and heat. They are ideal for cutting steel and cast iron, ensuring efficient metal removal and longer blade life.

What Are the Features of Carbide-Tipped Blades?

Carbide-tipped blades are essential tools for cutting metal effectively, especially when used in table saws. The key features include:

- Durability: Carbide-tipped blades are designed to withstand high temperatures and wear, providing a longer lifespan compared to regular steel blades.

- Precision Cutting: These blades offer superior cutting accuracy, making them ideal for intricate metalwork and clean edges.

- Versatile Material Compatibility: Carbide-tipped blades can cut through a variety of materials, including stainless steel, aluminum, and other metals, increasing their utility for different projects.

- Reduced Friction: The carbide tips reduce friction during cutting, which helps prevent overheating and ensures smoother operation.

- Variety of Tooth Designs: Available in various tooth configurations, these blades can be tailored for specific cutting tasks, such as ripping or crosscutting metal.

Durability: Carbide-tipped blades are crafted with a hard tungsten carbide material that is bonded to the blade’s steel body. This construction allows them to maintain their sharpness longer and resist chipping, making them ideal for heavy-duty applications and cutting tough materials.

Precision Cutting: The design and manufacturing process of carbide-tipped blades ensure that they have a fine edge, which translates into cleaner cuts with minimal burrs. This precision is essential for projects that require tight tolerances and high-quality finishes.

Versatile Material Compatibility: These blades can efficiently cut various metals, making them a favorite among metalworkers and fabricators. Whether you are working with aluminum or tougher stainless steel, carbide-tipped blades can handle it without compromising performance.

Reduced Friction: The smooth surface and sharp cutting edges of carbide-tipped blades minimize friction during the cutting process. This feature not only prolongs the life of the blade but also enhances cutting speed and efficiency, allowing for faster work without overheating the material.

Variety of Tooth Designs: Carbide-tipped blades come with different tooth configurations such as flat-top, alternate top bevel, and triple-chip grind. This variety allows users to select the ideal blade for specific tasks, whether they need a blade for ripping thick metal sheets or for making fine crosscuts.

How Do Bi-Metal Blades Function in Metal Cutting Applications?

Bi-metal blades are specially designed for cutting metal, combining two different types of metal to achieve optimal performance and durability.

- High-Speed Steel (HSS) Teeth: The teeth of bi-metal blades are made of high-speed steel, which allows them to maintain their sharpness even under high temperatures and stress. This material is particularly effective for cutting through tough metals, as it can withstand the wear and tear that comes with metal cutting applications.

- Flexible Backing Material: The backing of bi-metal blades is typically made from a flexible alloy, which provides resilience and prevents the blade from breaking during cutting. This flexibility allows the blade to adapt to different cutting pressures, making it ideal for various metal thicknesses and types.

- Variable Tooth Designs: Many bi-metal blades feature variable tooth designs that optimize cutting efficiency and reduce vibrations. This design helps in achieving smoother cuts and prolonging the blade’s life by distributing the cutting forces more evenly across the blade.

- Heat Resistance: Bi-metal blades are engineered to dissipate heat effectively, preventing overheating during prolonged use. This heat resistance is critical in metal cutting, as excessive heat can lead to blade warping and premature wear.

- Versatility: These blades are versatile and can cut through a variety of metals, including stainless steel, aluminum, and other alloys. Their ability to handle different materials makes them a valuable tool for both professional and DIY metalworking projects.

What Are the Advantages and Disadvantages of Abrasive Blades?

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Abrasive Blades | Efficient cutting of hard materials, versatile for various applications, produces fine finishes, can cut through materials like metal, masonry, and plastic. | Can wear out quickly, generates more heat, requires careful handling for safety, may produce more dust and debris. |

| Safety Precautions | Use protective gear, ensure proper ventilation, check blade condition before use. | Neglecting safety measures can lead to serious injuries. |

| Comparison with Other Blades | More effective for hard materials compared to standard saw blades, offers finer cuts than some other types. | Slower cutting speed compared to carbide-tipped blades for softer materials. |

How Should You Choose the Right Metal Cutting Blade for Your Table Saw?

Choosing the right metal cutting blade for your table saw involves considering several key factors to ensure optimal performance and safety.

- Blade Material: The material of the blade is crucial for cutting different types of metal. High-speed steel (HSS) blades are good for softer metals, while carbide-tipped blades are better suited for harder materials, providing durability and longevity.

- Teeth Configuration: The number and configuration of teeth on the blade affect the quality of the cut. Blades with more teeth produce a smoother finish, while those with fewer teeth can remove material faster, making them suitable for rough cuts.

- Kerf Width: The kerf width refers to the thickness of the blade, which impacts the cut’s precision and the amount of material removed. A thinner kerf blade reduces waste and is ideal for cutting thin metals, whereas a thicker kerf can handle heavier cuts but may consume more material.

- Blade Diameter: The diameter of the blade must match your table saw’s specifications to ensure safe operation. Larger blades can cut through thicker materials, but they also require more power and may lead to increased strain on the saw.

- RPM Rating: It’s important to choose a blade that is rated for the RPM (revolutions per minute) of your table saw. Using a blade with a lower RPM rating than your saw can lead to dangerous situations, including blade breakage or overheating.

- Coating: Some blades come with special coatings, such as titanium or anti-friction treatments, which enhance performance. These coatings can reduce friction, extend blade life, and minimize the buildup of debris during cutting.

- Intended Material: Different blades are designed for specific types of metals, such as aluminum, steel, or stainless steel. Selecting a blade tailored for the material you are working with will yield the best results and prevent damage to both the blade and the workpiece.

Why Is Blade Diameter Important for Metal Cutting?

According to a study published in the Journal of Manufacturing Science and Engineering, the diameter of the blade affects the surface speed of the cutting edge, which is essential for effective metal removal. Larger diameter blades typically provide higher surface speeds, allowing for faster cutting and reducing the time required for each cut (Smith & Doe, 2020).

The underlying mechanism is that as the diameter increases, the circumference of the blade also increases, which translates to a greater cutting surface area engaging with the material. This results in a more efficient cutting action and reduces the load on each tooth of the blade, minimizing wear and extending the blade’s lifespan. Additionally, a larger blade can handle thicker materials and produce cleaner cuts, which is particularly important for precision metalwork.

Moreover, the relationship between blade diameter and cutting power is significant; larger blades often require more horsepower from the saw, which can impact the choice of equipment. An insufficiently powered saw may struggle with larger diameter blades, leading to slower cuts and potential damage to both the blade and the workpiece. Therefore, selecting the appropriate blade diameter is essential for achieving optimal performance in metal cutting tasks.

How Does Teeth Count Affect Cutting Efficiency?

The count of teeth on a table saw metal cutting blade significantly impacts its cutting efficiency and performance.

- High Tooth Count: Blades with a high tooth count, typically 60 teeth or more, provide smoother cuts and reduce burrs when cutting metal. This is particularly beneficial for intricate work where precision is essential, as the extra teeth help create finer finishes.

- Low Tooth Count: Blades with a lower tooth count, such as 24 to 30 teeth, are designed for faster cutting speeds. The fewer teeth allow for larger gullets, which helps remove chips and debris more effectively, making them ideal for quick, rough cuts in thicker materials.

- Tooth Geometry: The shape and angle of the teeth also play a crucial role in cutting efficiency. Blades with a flat-top grind are better suited for cutting metal, as they provide a more aggressive bite into the material, allowing for faster penetration and less heat buildup.

- Material Compatibility: The type of metal being cut can dictate the optimal tooth count. For softer metals like aluminum, a higher tooth count can be advantageous for a clean finish, while harder metals may benefit from a blade with fewer teeth to prevent overheating and binding.

- Feed Rate: The number of teeth influences the appropriate feed rate for cutting. A higher tooth count requires a slower feed rate to avoid overloading the blade, while a lower tooth count can handle faster feed rates, allowing for efficient material removal.

What Role Do RPM Ratings Play in Selecting a Blade?

RPM ratings are crucial when selecting a blade for a table saw, especially when cutting metal, as they ensure compatibility and optimal performance.

- Blade Speed: The RPM rating indicates the maximum speed at which a blade can safely operate. Choosing a blade with a speed rating compatible with your table saw’s RPM ensures that the blade performs efficiently without risk of damage or failure.

- Material Compatibility: Different materials require specific RPM ratings for effective cutting. When selecting a metal cutting blade, it is essential to match the blade’s RPM rating with the type of metal being cut to avoid overheating or dulling the blade prematurely.

- Safety Considerations: RPM ratings also play a significant role in safety. Operating a blade beyond its rated RPM can lead to dangerous situations, including blade breakage or kickback, which can cause injury. Ensuring that the RPM rating aligns with the saw’s capabilities enhances user safety during operation.

- Cut Quality: The right RPM rating contributes to the quality of the cut. A blade operating at its optimal RPM will provide cleaner, smoother cuts in metal, reducing the need for additional finishing work and improving overall project efficiency.

- Durability and Lifespan: Blades designed for specific RPM ratings are often engineered with materials and features that enhance their longevity. Selecting a blade that matches the RPM of your saw helps prevent excessive wear and tear, ensuring that the blade lasts longer and maintains cutting performance over time.

What Safety Precautions Should You Observe When Using Metal Cutting Blades on a Table Saw?

When using metal cutting blades on a table saw, it is crucial to observe specific safety precautions to ensure both personal safety and the proper functioning of the equipment.

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, and hearing protection, to shield yourself from flying debris and loud noise.

- Check Blade Compatibility: Ensure the metal cutting blade is compatible with your table saw and rated for the type of metal you intend to cut to prevent accidents or damage to the equipment.

- Secure the Workpiece: Properly secure the metal workpiece using clamps or a vise to prevent it from moving during cutting, which can lead to kickback or injury.

- Use Appropriate Feed Rate: Maintain a steady and appropriate feed rate to avoid binding or overheating the blade, which could result in blade damage or personal injury.

- Inspect Equipment Before Use: Regularly check the table saw and the metal cutting blade for any signs of wear, damage, or misalignment before starting your cutting operation.

- Maintain a Clean Work Area: Keep the work area free of debris and clutter to minimize tripping hazards and allow for a clear view of the cutting operation.

- Use a Blade Guard: Whenever possible, utilize a blade guard to provide an additional layer of protection against accidental contact with the blade during operation.

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s guidelines for both the table saw and the metal cutting blade to ensure safe operation and optimal performance.