Footprint Heavy-Duty Brick Bolster Tool – 4 Inch/10cm Bricklaying Chisel, Concrete Breaker and Chopper. For Stone Masonry, Bricklayers and DIY Home Improvement. Cuts and Slices Bricks, Removes Mortar.

£12.32

ComparePrice: £12.32

(as of May 10,2024 13:30:59 UTC – Details)

From the manufacturer

Footprint Brick Bolster

Made in Sheffield, BritainHigh quality carbon steelFully forged from head to blade

Footprint Brick Bolsters

High carbon steel

Like all good chefs, good manufacturers rely on good ingredients.

All our steel comes from trusted European mills.

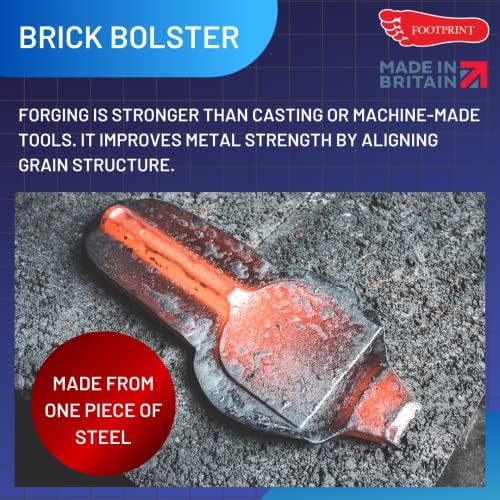

Head to blade forging

Unlike most brick bolsters we forge ours from head to blade, rather than just forging the blade.

This builds in more strength across the whole brick bolster rather than just the blade.

Hardening Brick Bolsters

Each Brick Bolster is hardened in a gas furnace and quenched in oil.

This hardens the blade to the right hardness meaning the blade holds an edge for longer.

Mushroom Head

All Footprint brick bolsters come as standard with a mushroom head.

This protects against the onset of mushrooming from repeated use.

Made in Britain

About Footprint

About Footprint

Footprint has been manufacturing hand tools in the UK since the 18th century. They continue to manufacture most of their tool range from their Sheffield based factory.

Footprint was forced to close temporarily when the 2008 recession struck while they were moving factories and investing in the future. They have since rebuilt themselves.

They’re owned by the 4th generation of the same family, with one of the main forgers being the current managing director.

Made in Britain

Footprint Tools

Footprint is a member of the Made in Sheffield and Made in Britain groups. These groups represent hundreds of Sheffield and UK wide manufacturers of high quality products.

Footprint still own and operate their Sheffield based factory where they specialise in the forging and heat treatment of steel, in particular the production of hand tools.

Most Footprint tools are still Made in Sheffield, Britain. Given the global nature of manufacturing a small number of products are imported.

ALWAYS BRITISH MADE: All of Footprint’s tools are manufactured in Sheffield, where we have an international reputation for steel-making. Each Footprint brick bolster goes through 14 manufacturing processes to transform a bar of high quality carbon steel into this incredibly strong and long-lasting toolbox staple.

HEAVY-DUTY: Drop-hammer forged from one piece of Carbon steel heated to 1240°c, gives this hand tool superior strength. Tapered at the neck to prevent snapping at the weakest point. It’s placed in a furnace at 850°c during the hardening process and then tempered to 240°c to decrease brittleness. The thick handle shaft adds durability and the blade itself has additional ribs down the side and centre for increased strength for cutting larger blocks and bricks. You won’t find a stronger bolster.

ANTI-MUSHROOM HEAD: The domed head delays the onset of mushrooming and splintering after repeated use. Sharp wide cutting edge for clean cuts. Can be used on tiles too. And the Blue paint finish provides high visibility on busy sites. We’ve thought of everything! That’s why Footprint tools are the preferred brand by professional builders and other tradesmen all over the globe.

250 YEARS MANUFACTURING EXPERIENCE: We know a thing or two about manufacturing quality hand tools and when we develop a product, it sets the benchmark in the industry. We’ve been manufacturing since the 18th century and focus on delivering affordable high quality apparatus. Stone masons rely on our quality tools for cutting brick every day… worldwide.

There are no reviews yet.