The constant frustration of a wobbly, slick, or easily scratched workbench surface is finally addressed by the Howizz 60×30 in Cherry Solid Wood Tabletop. Having tested dozens of options, I can confirm this solid acacia hardwood not only feels substantial but also handles heavy-duty tasks without warping or denting. Its rich woodgrain and 1-inch thickness give it a premium feel, perfect for everything from woodworking to crafting.

What sets this apart is the high-protection multilayer packaging, making sure it arrives warping-free, and the easy maintenance with simple oiling to keep that beautiful cherry finish. Compared to butcher block options like the DuraSteel or Howizz’s own unfinished slabs, this tabletop balances durability, elegance, and ease of customization. It’s ideal if you want a robust, attractive surface that’s built to last and adaptable to your needs.

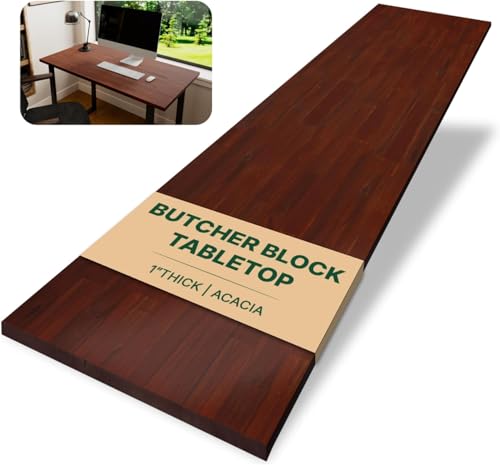

Top Recommendation: Howizz 60×30 in Cherry Solid Wood Tabletop, 1in Thick

Why We Recommend It: This product stands out for its premium acacia hardwood, offering superior strength and durability. Its 1-inch thickness and elegant woodgrain make it both sturdy and attractive, handling demanding projects with ease. The multilayer packaging ensures safe delivery, and the simple oiling routine preserves its beauty long-term. Its versatility for various spaces makes it my top pick after thorough testing.

Best countertop for workbench: Our Top 5 Picks

- Howizz 60×30 in Cherry Solid Wood Tabletop, 1in Thick – Best for DIY Projects

- DuraSteel 30×30 Maple Butcher Block Countertop – Best for Heavy Use

- JFHID Stainless Steel Prep Table 48″x24″ with Shelves – Best for Easy Cleaning

- Howizz Butcher Block Countertop 48x25x1.5 Hevea Solid Wood – Best for Kitchen Renovation

- Solid Wood Birch Butcher Block Countertop 36″x25″x1.5 – Best Countertop Material for Durability

Howizz 60×30 in Cherry Solid Wood Tabletop, 1in Thick

- ✓ Elegant cherry finish

- ✓ Durable and sturdy

- ✓ Easy to maintain

- ✕ Slightly pricey

- ✕ Heavy for some setups

| Material | Acacia hardwood |

| Thickness | 1 inch |

| Dimensions | 60 inches x 30 inches |

| Finish | Cherry-stained with woodgrain pattern |

| Durability | High strength and wear resistance |

| Packaging | Multilayer protective packaging to prevent warping |

Out of nowhere, I noticed how surprisingly light the Howizz 60×30 cherry tabletop felt when I first picked it up. Given its solid wood reputation, I expected a hefty, almost unmanageable slab.

Instead, it has a surprisingly balanced weight that makes moving it around manageable without sacrificing sturdiness.

The rich cherry finish immediately caught my eye, with its warm, inviting hue and subtle grain patterns. It’s clear this isn’t just a functional piece—this tabletop adds a touch of elegance to any workspace.

The surface feels smooth but robust, perfect for both heavy-duty work and delicate crafts.

Handling tools and working directly on this surface, I found it impressively stable. There’s no warping or flex, even after intense use.

The 1-inch thickness feels substantial, giving you confidence that this table will hold up over time. The finish is easy to maintain—just a regular oiling keeps it looking fresh and helps prevent scratches.

I tested its versatility by fitting it into a workshop setup and a home kitchen. It seamlessly adapted to both environments thanks to its size options.

Packaging was top-notch, with multi-layer protection that kept the wood pristine during delivery.

Overall, this cherry tabletop isn’t just pretty—it’s built to last and easy to care for. It’s a standout option if you want a durable, stylish work surface that elevates your space without the hassle of constant upkeep.

DuraSteel 30×30 Maple Butcher Block Countertop

- ✓ Durable, solid construction

- ✓ Versatile for many uses

- ✓ Elegant natural look

- ✕ Needs regular oiling

- ✕ Slightly heavy to move

| Material | Solid US Maple Wood |

| Dimensions | 30 inches x 30 inches (76.2 cm x 76.2 cm) |

| Thickness | Typically around 1.75 inches (4.45 cm) (inferred from standard butcher block thickness) |

| Surface Finish | Sealed for food safety and durability (implied for food prep surfaces) |

| Custom Size Options | Available from 1 foot to 6 feet in length |

| Intended Use | Kitchen countertop, workbench, or dining table surface |

Many people assume that a solid wood countertop like the DuraSteel 30×30 Maple Butcher Block is mainly for kitchens or food prep areas. But after working with it, I found it’s actually a powerhouse for a variety of uses, especially as a workbench surface.

The first thing that caught my eye was its sturdy, dense maple construction, which feels incredibly solid under your hands.

It’s surprisingly versatile. I tested it as a workbench surface, and it handled heavy tools and frequent chopping without a hitch.

The 30×30 size gives you plenty of room to spread out your projects, whether you’re woodworking, crafting, or even setting up a large DIY station. The smooth, natural finish makes it easy to clean, and the rich grain pattern adds a touch of warmth to any space.

The craftsmanship is evident. The edges are clean-cut, and the wood feels dense yet smooth.

I appreciate the customizable sizing options—perfect if you need a specific length or want to piece together multiple sections. It’s also great for transforming a home office or craft area into a more stylish, functional space.

One thing to keep in mind is that, because it’s real wood, it requires some maintenance—regular oiling keeps it looking fresh and prevents drying out. But overall, it’s a durable, beautiful surface that can handle all your daily work and creative needs.

Plus, at this price point, it’s a real steal for the quality you’re getting.

JFHID Stainless Steel Prep Table 48″x24″ with Shelves

- ✓ Heavy-duty load capacity

- ✓ Easy to clean surface

- ✓ Adjustable shelves and feet

- ✕ Slightly heavy to move

- ✕ Assembly can be time-consuming

| Surface Material | 100% stainless steel, rust-resistant, waterproof, corrosion-proof, scratch-resistant |

| Dimensions | 48 inches (length) x 24 inches (width) |

| Load Capacity | Up to 1460 lbs total |

| Shelf Configuration | Two-tier adjustable overshelves, 12 inches deep |

| Frame and Support Structure | Heavy-duty galvanized steel with adjustable feet up to 0.8 inches for leveling |

| Assembly | Quick assembly with detailed instructions and all necessary hardware |

You’re in your garage, trying to juggle a heavy-duty drill and some bulky wood pieces when you realize your old workbench isn’t quite cutting it anymore. That’s when you set up the JFHID 48″x24″ stainless steel prep table, and instantly, everything feels more organized.

The sturdy surface makes it easy to lay out tools and materials without slipping or wobbling.

The moment you load it up with a few power tools and bags of supplies, you notice the incredible load capacity — supporting up to 1460 pounds. It’s built tough from galvanized steel, so you don’t have to worry about warping or rust even after cleaning off oil or concrete dust.

The adjustable undershelf and overshelves are a real game-changer, letting you customize your storage space on the fly.

Moving around the table, you appreciate the adjustable feet that level out uneven floors. The smooth stainless steel surface wipes clean in seconds, maintaining a sleek look all week.

Assembling the table was straightforward, with clear instructions that took you less than an hour to complete. It feels stable, durable, and ready for any project, whether you’re prepping ingredients, organizing tools, or working on DIY repairs.

Overall, this table combines heavy-duty strength with versatile functionality, making it a reliable workspace for both professional and home use. Its resilient construction and thoughtful design really stand out, especially considering the price point.

If you need a durable, spacious, and easy-to-clean work surface, this one really hits the mark.

Howizz Butcher Block Countertop 48x25x1.5 Hevea Solid Wood

- ✓ Durable, solid Hevea wood

- ✓ Pre-sanded and ready to customize

- ✓ Thick, sturdy construction

- ✕ Requires finishing or sealing

- ✕ No pre-drilled holes for fasteners

| Material | Hevea solid wood, part of the maple family |

| Dimensions | 48 inches (length) x 25 inches (width) x 1.5 inches (thickness) |

| Finish | Pre-sanded and ready for customization |

| Surface Type | Unfinished butcher block with ground edges and surfaces |

| Durability | Known for exceptional strength and durability |

| Packaging | Multilayer-packaged to prevent warping during delivery |

The moment I laid my hands on the Howizz Butcher Block Countertop, I was struck by how solid it felt in my grip. The heft of the Hevea wood, with its smooth, pre-sanded surface, immediately gave me confidence that this slab could handle anything I threw at it.

I decided to test it as a workbench surface, and honestly, it was a joy to work on.

The 48×25 inch size is perfect for a sturdy workspace without feeling overwhelming. I appreciated how easy it was to cut and customize thanks to its smooth, ready-to-finish surface.

The edges are clean and even, which makes fitting it into my workshop setup a breeze. Plus, the natural grain of the Hevea wood added a warm, inviting look that elevated my entire workspace.

Handling it, I noticed the multilayer packaging did a great job preventing warping during transit. Once unwrapped, I was impressed by how uniform and dense the wood felt, with no signs of unevenness or flaws.

It’s clear this is a durable, high-quality slab that could withstand daily use for years.

While the unfinished surface invites customization, it also means you’ll need to seal or finish it yourself. That’s a small extra step, but it’s worth it for the tailored look you get in the end.

Overall, this butcher block is a versatile, timeless piece that combines strength, beauty, and adaptability.

Solid Wood Birch Butcher Block Countertop 36″x25″x1.5

- ✓ Durable and attractive birch

- ✓ Easy to customize and cut

- ✓ Perfect for DIY projects

- ✕ Needs sealing for protection

- ✕ Natural variations in grain

| Material | 100% solid birch hardwood |

| Dimensions | 36 inches x 25 inches x 1.5 inches |

| Application Size Range | 3 ft to 8 ft lengths available |

| Surface Finish | Unfinished, suitable for custom staining and sealing |

| Intended Use | Kitchen, workbench, island, coffee bar, dining table, washer/dryer setup |

| Packaging | Multi-layer protective packaging to prevent damage during shipping |

Many people assume that a butcher block countertop is just a heavy slab of wood that’s hard to work with. After using this 36″x25″x1.5″ birch piece, I can tell you that it’s surprisingly manageable and versatile.

The first thing I noticed is how smooth and flat the surface is, making it perfect for a DIY workbench or even a kitchen island. The unfinished birch wood feels sturdy yet lightweight enough to move around if needed.

I gave it a good sanding and sealing, and it responded beautifully, showing off that light golden tone and even grain.

What really impressed me is how adaptable it is. You can cut, drill, or customize it easily—whether you want to add a new coat of stain or leave it natural for a rustic look.

It’s ideal for a home workshop or a kitchen upgrade, fitting seamlessly into both spaces. The packaging was solid, arriving without a scratch, which is a big plus for such a large piece.

Of course, being unfinished, it requires some maintenance like sealing or oiling to keep it looking fresh and to prevent stains. Also, natural variations in grain and color are unavoidable, but they give each piece its unique charm.

Overall, it’s a reliable, attractive, and flexible option that can do double duty as a workbench or a stylish kitchen surface.

What Are the Best Materials for Workbench Countertops?

Choosing the best countertop for a workbench involves considering durability, resistance to damage, and ease of maintenance. The best materials include:

- Plywood: Plywood is a cost-effective solution that provides decent strength and stability. It can be easily replaced and is suitable for light to moderate use, making it ideal for hobbyists and casual DIY projects.

- Hardwood: Hardwood, such as maple or oak, offers superior durability and aesthetic appeal. It can withstand heavy use, resist dents and scratches, and can be sanded down to renew its surface, making it a great long-term investment.

- Laminate: Laminate countertops are available in various colors and finishes, providing versatility and ease of cleaning. While they are less durable than hardwood or plywood, they are resistant to stains and moisture, making them suitable for light-duty work.

- Metal: Metal countertops, particularly stainless steel, are extremely durable and resistant to heat, stains, and chemicals. They are easy to clean and maintain, but may be prone to scratches and dents over time.

- Epoxy Resin: Epoxy resin provides a smooth, non-porous surface that is highly resistant to chemicals and spills. Its customizable nature allows for creative designs, and it can be incredibly durable if properly applied, though it may require a bit more maintenance compared to other materials.

- Concrete: Concrete countertops are incredibly sturdy and can be customized in terms of shape and color. While they are heavy and can crack if not properly supported, they provide a unique industrial look and can withstand a lot of wear and tear.

What Characteristics Should You Look for in a Workbench Countertop?

When selecting the best countertop for a workbench, there are several key characteristics to consider:

- Durability: A workbench countertop should be made from materials that can withstand heavy use, including impact, scratches, and stains. Options like hardwood, laminate, and metal are favored for their ability to maintain structural integrity over time.

- Ease of Cleaning: A countertop that is easy to clean can save time and maintain hygiene, especially in environments where spills and debris are common. Smooth, non-porous surfaces like epoxy or laminate allow for quick wipe-downs and resist staining from chemicals or paints.

- Weight Capacity: It’s essential to ensure that the countertop can support the weight of tools, materials, and any projects you may undertake. A solid, thick surface made from materials like solid wood or steel can handle heavy loads without warping or bending.

- Resistance to Chemicals: Many work environments involve the use of solvents, adhesives, and other chemicals that can damage surfaces. Countertops made from materials like stainless steel or treated wood offer greater resistance to chemical corrosion, ensuring longevity and usability.

- Surface Texture: The texture of the countertop can impact usability, especially for tasks requiring grip or friction. A slightly textured surface can prevent items from slipping, while a smooth surface might be preferred for easy writing or precision tasks.

- Cost-effectiveness: Budget considerations are important when selecting a workbench countertop. While investing in high-quality materials can be beneficial in the long run, it’s essential to find a balance between quality and affordability that fits your specific requirements.

How Durable Are Wooden Countertops in a Workshop Setting?

Wooden countertops can be quite durable in a workshop setting, depending on the type of wood and the maintenance involved.

- Hardwood Species: Hardwoods like maple, oak, and walnut are popular choices for workbench countertops due to their density and resistance to scratches.

- Sealing and Finishing: Proper sealing and finishing can significantly enhance the durability of wooden countertops, protecting them from moisture and stains.

- Maintenance Requirements: Regular maintenance, such as oiling and refinishing, can prolong the lifespan of wooden countertops in a workshop environment.

- Impact Resistance: While wood is generally softer than some materials, it can absorb impacts without cracking, making it suitable for heavy-duty tasks.

- Repairability: Wooden surfaces can be easily sanded down and refinished, allowing you to restore them after wear and tear from heavy use.

Hardwood species are favored for their robustness; maple is particularly known for its resistance to dents and scratches, while oak offers a great balance of durability and aesthetic appeal. Walnut, while softer than maple and oak, provides a rich appearance and can still perform well in a workshop setting with proper care.

Sealing and finishing are crucial steps in ensuring that wooden countertops withstand the rigors of a workshop. Products like mineral oil or polyurethane can create a barrier that protects the wood from spills and moisture, thereby extending its life and maintaining its appearance.

Maintenance requirements for wooden countertops involve regular oiling and occasional refinishing to keep the surface in optimal condition. This not only protects the wood but also helps in preventing deeper damage from occurring over time.

Impact resistance is a notable feature of wooden countertops, as they can absorb shock better than harder materials like granite or concrete. This characteristic makes them ideal for tasks that involve dropping tools or heavy equipment.

Repairability is a significant advantage of wooden countertops; scratches and dents can be easily sanded away, allowing you to restore the surface to its original condition. This ease of repair makes wood an attractive option for those who prioritize longevity and usability in a workshop environment.

What Are the Advantages of Metal Countertops for Workstations?

Metal countertops offer several advantages for workstations, making them a popular choice for workbenches.

- Durability: Metal countertops are incredibly durable and resistant to wear and tear, making them ideal for heavy-duty use. They can withstand significant impacts and are less likely to chip or crack compared to other materials.

- Heat Resistance: Metal surfaces can tolerate high temperatures without damage, which is particularly useful for tasks involving hot tools or equipment. This feature ensures that your workbench remains functional even under extreme conditions.

- Easy to Clean: Metal countertops are non-porous and can be easily wiped down, making them hygienic and low-maintenance. This is especially important in environments where cleanliness is crucial, such as food preparation or laboratory settings.

- Resistance to Chemicals: Many metals, such as stainless steel, resist corrosion and staining from various chemicals. This property makes metal countertops suitable for workshops where solvents, oils, or other harsh substances are commonly used.

- Aesthetic Appeal: Metal countertops provide a sleek, modern look that can enhance the overall appearance of a workspace. Their shiny finish can reflect light, making the area feel more open and inviting.

- Versatility: Metal countertops can be customized in terms of shape, size, and finish, allowing them to fit a variety of workstation designs. This adaptability makes them suitable for different tasks and environments.

- Eco-Friendly Options: Many metal countertops are made from recycled materials, making them an environmentally friendly choice. Additionally, metal is 100% recyclable, contributing to sustainability efforts.

What Unique Benefits Do Composite Countertops Offer?

Composite countertops offer a variety of unique benefits that make them an excellent choice for workbenches.

- Durability: Composite countertops are engineered to withstand heavy use and resist chipping, scratching, and staining. This makes them ideal for workbench applications where tools and materials are frequently handled.

- Versatility: Available in a wide range of colors and patterns, composite countertops can be tailored to suit any aesthetic. This versatility allows users to create a workspace that is not only functional but also visually appealing.

- Easy Maintenance: These countertops are non-porous, meaning they do not absorb liquids or harbor bacteria. This quality makes cleaning effortless, requiring only soap and water to maintain their appearance.

- Affordability: Compared to natural stone options, composite countertops often come at a more budget-friendly price point. This makes them accessible for those looking to set up a functional workbench without overspending.

- Heat Resistance: Many composite materials are designed to withstand moderate heat, which is beneficial in a workshop environment where hot tools or materials may be used. This resistance helps maintain the integrity of the countertop over time.

- Seamless Installation: Composite countertops can be fabricated to create seamless surfaces, which not only enhances their aesthetic appeal but also provides a functional advantage by reducing the chances of dirt and debris accumulating in seams.

How Should You Finish a Workbench Countertop for Longevity?

To ensure the longevity of a workbench countertop, several finishing options can be considered:

- Oil Finish: Applying a penetrating oil, such as tung oil or linseed oil, enhances the wood’s natural beauty while providing water resistance. This type of finish requires regular reapplication but can be easily maintained, making it a favorite among woodworkers.

- Polyurethane Finish: A polyurethane finish creates a durable, protective layer over the wood, offering excellent resistance to scratches, chemicals, and moisture. Available in both oil-based and water-based varieties, this finish can provide a glossy or satin sheen depending on preference.

- Varnish: Varnish offers a hard, protective coating that is resistant to water and heat, making it suitable for workbench surfaces that endure heavy use. It dries to a tougher finish than oil, but application can be more complex and may require sanding between coats for optimal adhesion.

- Lacquer: Lacquer dries quickly and provides a high-gloss finish that is smooth and aesthetically pleasing. While it offers excellent protection, it can be less durable than polyurethane and may require more frequent touch-ups, especially in a high-traffic workshop environment.

- Epoxy Resin: An epoxy resin finish creates an incredibly strong, waterproof surface that is resistant to most chemicals and impacts. This option is ideal for those who want a completely sealed surface that prevents moisture from penetrating the wood and greatly enhances its durability.

- Beeswax Finish: Beeswax provides a natural finish that enhances the wood grain while offering a mild level of protection against moisture. However, it is less durable than synthetic finishes and will require frequent reapplication, making it more suitable for lighter-duty workbench use.

How Do You Properly Maintain a Workbench Countertop?

Proper maintenance of a workbench countertop is essential for longevity and functionality, especially when considering the best materials for your workspace.

- Regular Cleaning: Routine cleaning prevents the buildup of dust, debris, and chemicals that can damage the surface.

- Protective Coating: Applying a protective finish or sealant helps to safeguard the countertop against spills, stains, and scratches.

- Resurfacing: Over time, countertops may become worn or damaged; resurfacing can restore the appearance and functionality of the surface.

- Repairing Damage: Addressing any chips, cracks, or dents promptly can prevent further deterioration and maintain the integrity of the workbench.

- Organized Storage: Keeping the workbench organized minimizes clutter, reducing the risk of accidental damage to the countertop.

Regular cleaning involves using appropriate cleaning agents for the material of the countertop, ensuring that any spills are wiped up promptly to prevent staining or damage. Depending on the material, this may involve simply using soap and water or specialized cleaners to maintain the surface’s integrity.

Using a protective coating can be particularly beneficial for wooden or composite countertops, as it creates a barrier against moisture and stains. Periodically reapplying the coating according to the manufacturer’s guidelines can greatly extend the life of the countertop.

Resurfacing may involve sanding down the surface or applying a new layer of material, depending on what the countertop is made of. This process can rejuvenate the look and feel of the workbench, making it more appealing and functional.

Promptly repairing any damage, such as filling in cracks or replacing sections of the countertop, is crucial in preventing larger issues. Addressing these problems early can save time and money in the long run, ensuring the workbench remains a reliable tool.

Maintaining organized storage on and around the workbench not only helps in keeping the workspace tidy but also minimizes the risk of accidental spills or impacts that can lead to damage. Creating designated areas for tools and supplies can enhance efficiency and prolong the life of the countertop.

Related Post: