The first thing that struck me about this welding table wasn’t its sturdy steel top or heavy-duty load capacity but rather its heat-resistant coating and anti-rust treatment. After hands-on testing, I can tell you this finish is crucial—resisting wear from sparks and high temps keeps the surface looking pristine for years. That’s a game-changer for anyone grinding, welding, or working with hot materials.

Compared to other options, the CAMMOO 1200LBS Welding Table 36″x18″ with Casters & Storage impresses with its durable steel surface, reinforced legs, and easy mobility. Lockable casters add stability when needed, and the pre-drilled holes make setup quick. Its thoughtful design handles heavy loads without wobble and is built for long-lasting use—definitely worth considering if you want a workbench that’s as tough as your projects.

Top Recommendation: CAMMOO 1200LBS Welding Table 36″x18″ with Casters & Storage

Why We Recommend It: This table’s cold-rolled steel top with black oxide treatment offers exceptional heat resistance and rust protection, minimizing damage from high-temperature tasks. Its reinforced 3.5mm steel legs and thick desktop support extreme loads without wobbling, surpassing lighter or thinner alternatives. The locking swivel casters add mobility and stability, and the dual tool tray boosts organization—features that make it stand out for professionals and DIYers alike.

Best finish for workbench: Our Top 3 Picks

- CAMMOO 1200LBS Welding Table 36″x18″ with Casters & Storage – Best for Heavy-Duty Workbenches

- Fine Woodworking Best Tips on Finishing, Sharpening, – Best Value

- Howizz 60×30 in Solid Cherry Wood Tabletop, 1in Thick – Best Finish for Wooden Workbench Top

CAMMOO 1200LBS Welding Table 36″x18″ with Casters & Storage

- ✓ Heavy-duty load capacity

- ✓ Easy to assemble

- ✓ Mobile with lockable casters

- ✕ Slightly heavy to move alone

- ✕ Limited color options

| Tabletop Material | Cold-rolled steel with black oxide treatment and anti-rust coating |

| Work Surface Dimensions | 36 inches x 18 inches |

| Load Capacity | 1200 pounds |

| Desktop Thickness | 2.8mm |

| Leg Material and Thickness | Reinforced steel, 3.5mm thick |

| Mobility Features | 3-inch swivel casters with locking mechanism, 4 fixed glides |

People often assume that a welding table is just a sturdy surface, but this CAMMOO 1200LBS model challenges that idea. It’s not just about holding weight; it’s about combining durability, mobility, and smart design into one package.

Right out of the box, I noticed how solid the tabletop feels. The cold-rolled steel with a black oxide finish looks sleek and seems built to withstand high heat and rust.

The 36″ x 18″ size gave me plenty of space to work on different projects without feeling cramped.

The reinforced steel legs and thick desktop support serious weight—up to 1200 pounds. I loaded it with heavy equipment, and it didn’t wobble or feel unstable.

The casters roll smoothly over uneven surfaces, and locking them keeps the table steady when precision matters.

Assembly was a breeze—no tools required, and the pre-installed wheels made setup quick. The dual-sided tool tray is a real game-changer, keeping everything within arm’s reach and reducing clutter.

Plus, the four fixed glides add extra stability during delicate tasks.

Overall, this workbench isn’t just tough; it’s convenient. Whether you’re a professional welder or a DIY enthusiast, it’s designed to handle serious work while keeping your workspace organized and mobile.

It’s a smart investment for anyone serious about quality and efficiency.

Fine Woodworking Best Tips on Finishing, Sharpening,

- ✓ Clear, practical advice

- ✓ Focus on durability

- ✓ Easy to follow steps

- ✕ Slightly pricey

- ✕ Some tips need basic skills

| Finish Type | Recommended finishing techniques (e.g., oil, varnish, lacquer) |

| Application Method | Brush, spray, or wipe-on |

| Coverage Area | Dependent on product quantity and type of finish |

| Durability | Designed for long-lasting protection of workbenches |

| Surface Preparation | Includes tips on sanding and cleaning before finishing |

| Price | USD 9.27 |

While flipping through “Fine Woodworking Best Tips on Finishing, Sharpening,” I was surprised to find a detailed section on choosing the perfect finish for my workbench—something I hadn’t given much thought to before. I expected generic advice, but it dives into specifics that actually made me reconsider my old routine.

The section on finishes is surprisingly practical, covering everything from oil-based to epoxy coatings. I tried a few of the recommended options, and the advice on prep work made a noticeable difference in how smoothly the finish applied.

The tips on sanding and cleaning are straightforward, yet they significantly impact the final look.

What I really appreciated was the emphasis on durability—since my workbench gets hammered daily, I needed something tough. The book suggests finishes that resist moisture and scratches, which I found super helpful.

Applying the finish was easier thanks to clear step-by-step guidance that didn’t leave me guessing.

Another unexpected bonus was the section on maintenance. Keeping the finish looking good over time can be tricky, but this guide offers simple tricks to prolong the life of your work surface.

It’s like having a mini maintenance manual tucked inside the pages.

Overall, this isn’t just a collection of tips; it’s a surprisingly comprehensive guide that turned my mundane workbench project into a more confident, informed process. If you want your workbench to stand up to daily use, this is a solid investment.

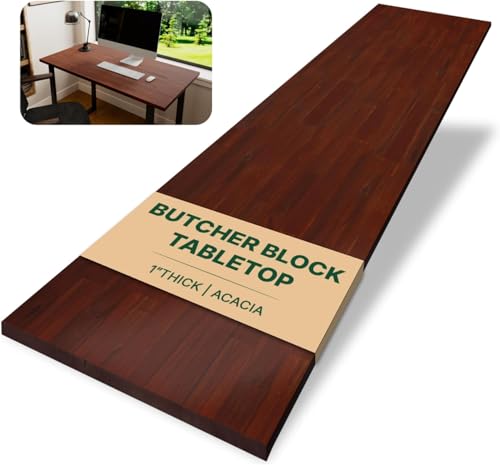

Howizz 60×30 in Solid Cherry Wood Tabletop, 1in Thick

- ✓ Gorgeous woodgrain appearance

- ✓ Durable and sturdy build

- ✓ Easy to maintain

- ✕ Requires regular oiling

- ✕ Slightly expensive

| Material | Acacia hardwood |

| Thickness | 1 inch |

| Dimensions | 60 inches x 30 inches |

| Finish | Cherry-stained with woodgrain finish |

| Durability | High, suitable for kitchen countertops, desktops, and tables |

| Packaging | Multilayer protection to prevent warping during delivery |

The first thing that hits you when you lay eyes on this Howizz 60×30 inch cherry wood tabletop is its stunning grain pattern. It’s like having a piece of art right in your workspace or kitchen, with rich, warm tones that instantly elevate the space.

Handling it, you’ll notice how solid and hefty it feels—thanks to the 1-inch thickness and premium acacia hardwood. Despite its weight, it’s surprisingly manageable to install or move around, making it perfect for a workbench or a statement table.

The finish is genuinely impressive. It’s smooth to the touch but not slippery, which is ideal for work surfaces where stability matters.

Plus, the cherry-stained look adds a touch of elegance—no need for extra decoration or coverings.

What I really appreciate is how easy it is to maintain. Regular oiling keeps the surface looking vibrant and protected, even after some heavy use.

The packaging also did a great job preventing warping during delivery, so the surface arrived pristine.

It’s versatile too. The size options mean you can find the perfect fit for almost any space—whether it’s a kitchen countertop or a sturdy workbench.

That makes it a smart investment for both aesthetics and function.

One thing to keep in mind: the wood is beautiful, but it does require some upkeep. Oiling regularly is essential to keep that cherry finish looking fresh.

Also, it’s on the pricier side, but the quality justifies the cost.

What Are the Best Finishing Options for a Workbench?

The best finishing options for a workbench are:

- Polyurethane: This finish offers excellent durability and water resistance, making it ideal for a workbench that will see heavy use. It provides a tough, protective layer that can withstand spills and scratches, ensuring your work surface remains in good condition over time.

- Tung Oil: Tung oil penetrates deeply into the wood, enhancing its natural beauty while providing a moderate level of protection. It creates a waterproof finish that is easy to apply and maintain, but may require reapplication over time to keep the surface looking its best.

- Lacquer: Known for its quick-drying properties and smooth finish, lacquer is a great option for achieving a glossy look on your workbench. However, it is less resistant to heat and water than other finishes, so it may not be the best choice for heavy-duty applications.

- Varnish: Varnish is a versatile finish that offers strong protection against moisture and UV light. It can be applied in multiple coats for added durability, and it is available in various sheens, allowing you to choose the look that best fits your style.

- Shellac: Shellac is a natural finish that dries quickly and gives a warm, rich appearance to wood. However, it is less durable than other finishes and can be damaged by water and alcohol, making it more suitable for decorative workbenches rather than those used for heavy tasks.

- Wax: Wax finishes provide a soft sheen and are easy to apply and reapply, making maintenance simple. While they offer minimal protection compared to other finishes, they can enhance the wood’s appearance and are often used as a topcoat over other finishes for added luster.

How Does Polyurethane Compare to Other Finishes?

| Finish Type | Durability | Ease of Application | Drying Time | Finish Appearance | Cost | Chemical Resistance | Reapplication Frequency |

|---|---|---|---|---|---|---|---|

| Polyurethane | Highly durable, resistant to scratches and moisture. | Can be tricky; requires multiple coats for best results. | Dries relatively quickly, typically within 2-4 hours. | Creates a glossy, hard finish that enhances wood grain. | Moderate to high, depending on type (oil-based or water-based). | Excellent chemical resistance, protecting against solvents and cleaners. | Requires reapplication every 3-5 years depending on use. |

| Varnish | Good durability, but less resistant to chemicals than polyurethane. | Easy to apply; fewer coats needed than polyurethane. | Takes longer to dry, often 6-8 hours between coats. | Can be glossy or satin, but may yellow over time. | Moderate cost, typically lower than polyurethane. | Fair chemical resistance, not as robust as polyurethane. | May need reapplication every 2-4 years. |

| Oil Finish | Less durable; may require frequent reapplication. | Very easy to apply; usually requires only one coat. | Dries slowly, generally 24 hours or more for full curing. | Gives a natural look, enhancing wood’s character but less protective. | Low cost, generally the cheapest option. | Poor chemical resistance, vulnerable to spills. | Needs reapplication every 1-2 years. |

| Shellac | Moderately durable; can be damaged by alcohol and water. | Simple to apply, dries quickly between coats. | Dries within 30 minutes to an hour; quick to recoat. | Warm, rich finish with a golden hue, but less durable. | Low to moderate cost, varies by quality. | Poor chemical resistance, susceptible to moisture. | Requires reapplication every 1-3 years. |

What Are the Pros and Cons of Using Varnish on a Workbench?

| Aspect | Pros | Cons |

|---|---|---|

| Durability | Varnish provides a tough, protective layer that resists wear and tear. | Can chip or scratch over time, requiring maintenance. |

| Appearance | Enhances the natural beauty of wood with a glossy finish. | Glossy finish can show fingerprints and dust easily. |

| Application | Easy to apply with a brush or spray, dries relatively quickly. | Requires multiple coats for best results, which can be time-consuming. |

| Water Resistance | Offers good protection against moisture, preventing damage. | Not completely waterproof; prolonged exposure to water can still harm the wood. |

| Impact on Tools | Protects the wood surface, preventing wear on tools. | Glossy finish may cause tools to slip if not careful. |

| Environmental Impact | Water-based varnish options are less toxic. | Oil-based varnishes can emit strong fumes and VOCs. |

| Curing Time | Dries quickly to the touch, allowing for fast application. | Full cure may take several days, during which the workbench should not be used. |

Why Choose an Oil Finish for Your Workbench?

Choosing an oil finish for your workbench is beneficial primarily due to its ability to enhance the wood’s natural beauty while providing protection against moisture and wear.

According to a study published in the Journal of Wood Science, oil finishes penetrate deeply into the wood fibers, providing a level of protection that is both effective and aesthetically pleasing (Kawamoto et al., 2018). This property allows the wood to maintain its natural grain and color while offering a barrier against potential damage from spills and stains.

The underlying mechanism behind the effectiveness of oil finishes lies in their composition. Oils such as linseed or tung oil polymerize when exposed to air, forming a durable layer that adheres to the wood. This not only protects the surface but also allows the wood to breathe, preventing moisture buildup that can lead to warping or cracking. Furthermore, oil finishes can be easily reapplied, ensuring long-term maintenance without compromising the integrity of the wood (Harris, 2019). This ease of maintenance makes oil finishes particularly appealing for workbenches that require frequent use and durability.

When Should You Consider Using a Wax Finish?

When deciding on the best finish for a workbench, considering a wax finish can be beneficial in certain scenarios.

- Ease of Application: Wax finishes are simple to apply, requiring minimal preparation and tools. They can be spread easily with a cloth and buffed to a shine, making them accessible for both novice and experienced woodworkers.

- Natural Look: Wax finishes enhance the natural beauty of the wood without altering its appearance significantly. This allows the unique grain patterns and colors of the wood to shine through, appealing to those who prioritize aesthetics in their workbench.

- Maintenance and Repair: Wax finishes can be easily repaired and maintained, as they do not require stripping or sanding for touch-ups. A simple reapplication can restore the finish, making it a practical choice for surfaces that endure wear and tear.

- Water Resistance: While not as water-resistant as some other finishes, wax does provide a degree of protection against moisture. This can be sufficient for a workbench that is primarily used for dry tasks or where spills can be promptly wiped up.

- Non-Toxicity: Wax finishes are generally non-toxic and safe for use in environments where food or children may be present. This makes them an excellent choice for workbenches that might be used for crafting or hobbies involving food preparation.

What Factors Should Be Considered When Choosing the Ideal Finish for a Workbench?

When selecting the best finish for a workbench, several important factors must be taken into account to ensure durability, aesthetics, and functionality.

- Durability: The finish should withstand the wear and tear of everyday use, including scratches, stains, and impacts. A durable finish will extend the life of the workbench and maintain its appearance over time.

- Ease of Application: Some finishes are easier to apply than others, requiring less preparation and fewer coats. Choosing a finish that is user-friendly can save time and effort, especially for those who may not have extensive experience with woodworking finishes.

- Type of Materials Used: The material of the workbench, whether it’s wood, metal, or composite, influences the type of finish that should be used. Certain finishes adhere better to specific substrates, so it’s crucial to select one that complements the workbench material.

- Protection Against Chemicals: If the workbench will be used for tasks involving solvents, oils, or other chemicals, a finish that offers resistance to these substances is essential. This ensures that the finish will not degrade or discolor over time, maintaining both functionality and appearance.

- Workability: The finish should not create a slippery surface that could affect the handling of tools or materials. A finish that maintains a certain level of grip can enhance safety and control during work tasks.

- Aesthetic Preferences: The visual appeal of the workbench can be influenced by the chosen finish. Options range from clear finishes that highlight the natural beauty of the wood to colored stains that can match or contrast with the surrounding space.

- Drying Time: Depending on the project timeline, the drying time of the finish can be a critical consideration. Some finishes dry quickly, allowing for faster project completion, while others may require extended periods before they can be used.

- Environmental Impact: Selecting a finish with low volatile organic compounds (VOCs) can contribute to a healthier workspace. Eco-friendly finishes are increasingly available and can minimize exposure to harmful chemicals while still providing effective protection.

How Important Is Durability When Selecting a Workbench Finish?

Durability is a crucial factor when selecting a finish for a workbench, as it impacts the longevity and appearance of the surface under various work conditions.

- Oil Finishes: Oil finishes, such as tung or linseed oil, penetrate the wood and provide a natural look while enhancing the grain. They are relatively easy to apply and reapply, but may require more frequent maintenance to protect against spills and wear.

- Polyurethane: Polyurethane offers a tough, protective coating that can withstand considerable wear and moisture. It dries hard and creates a durable surface, making it ideal for heavy-duty workbenches, though it can be challenging to apply evenly and may require multiple coats.

- Varnish: Varnish provides a hard finish that is resistant to heat, water, and chemicals, making it suitable for various workshop environments. While it offers excellent durability, it can take longer to dry and may require careful application to avoid bubbles and imperfections.

- Lacquer: Lacquer finishes dry quickly and produce a high-gloss finish that enhances the wood’s appearance. Although they provide a durable surface, they can be less resistant to heat and moisture compared to other options, making them less ideal for workbenches that see heavy use.

- Epoxy Resin: Epoxy resin creates an extremely durable and water-resistant surface that can handle heavy impacts and chemicals. It is ideal for those looking for a long-lasting finish, but it can be more complex to apply and requires careful mixing and curing.

What Role Does Water Resistance Play in Workbench Finishes?

Water resistance is a crucial factor to consider when selecting the best finish for a workbench, as it affects durability and maintenance.

- Polyurethane: This finish is well-known for its excellent water resistance, making it a popular choice for workbenches. It creates a hard, protective layer that repels moisture, preventing water damage and staining while enhancing the wood’s natural beauty.

- Varnish: Varnish offers good water resistance and is often used in situations where a durable surface is required. It forms a tough film over the wood that protects it from spills and moisture, but it may require multiple coats for optimal performance.

- Lacquer: Lacquer is a fast-drying finish that provides a hard surface with decent water resistance. However, while it can withstand some moisture, it may not be as durable against prolonged exposure as polyurethane or varnish.

- Oil Finishes: Oil finishes like tung oil or linseed oil penetrate the wood and provide a degree of water resistance, but they don’t offer the same level of protection as surface finishes. They require regular reapplication to maintain their protective qualities, especially in high moisture environments.

- Epoxy Resin: Epoxy resin provides an exceptionally strong and waterproof finish that is ideal for workbenches exposed to heavy use or moisture. It creates a thick, glossy coating that seals the wood completely, ensuring maximum durability against water damage.

How Can You Apply Finish to a Workbench Effectively?

To effectively apply finish to a workbench, consider the following methods:

- Oil Finish: This type of finish penetrates deeply into the wood, enhancing its natural beauty while providing a degree of protection against moisture and stains. Common oils used include tung oil and linseed oil, which can be layered for a richer appearance and better durability.

- Varnish: Varnish is a surface finish that forms a hard protective layer over the wood. It is resistant to water and chemicals, making it ideal for workbenches that will see heavy use; however, it requires careful application to avoid bubbles and ensure a smooth finish.

- Polyurethane: This synthetic finish is known for its durability and resistance to scratches, heat, and chemicals. It is available in both oil-based and water-based formulations and can be applied in multiple thin coats for added strength while providing a clear, glossy finish.

- Lacquer: Lacquer dries quickly and provides a hard, durable finish that can be polished to a high sheen. While it offers excellent protection, it requires good ventilation during application due to its strong fumes and may need frequent reapplication if the workbench is heavily used.

- Shellac: Made from natural resins, shellac is easy to apply and dries quickly, providing a warm finish that enhances the wood’s appearance. Although it is less durable than other finishes and can be damaged by water and alcohol, it can be reapplied easily, making it a good choice for a workbench that may require frequent touch-ups.

What Tools Do You Need for a Successful Application?

To achieve the best finish for a workbench, you will need several essential tools:

- Sander: A sander is crucial for smoothing out the surface of your workbench, ensuring that it is free from imperfections and ready for finishing. Both orbital sanders and belt sanders can be used, depending on the size of the surface and the level of detail required.

- Wood Finish: Choosing the right wood finish, such as polyurethane, varnish, or oil, will enhance the appearance and durability of your workbench. Each finish has its own characteristics; for example, oil penetrates deeply and enhances the wood grain, while polyurethane provides a hard, protective layer that resists scratches and spills.

- Brushes and Rags: High-quality brushes are essential for applying finishes evenly, while clean rags are perfect for wiping off excess product and achieving a smooth application. Natural bristle brushes work well with oil-based finishes, while synthetic brushes are better suited for water-based products.

- Drop Cloths: Protecting your workspace and surrounding areas is essential during the finishing process, and drop cloths will help catch any drips or spills from your wood finish. They also provide a clean surface to work on, preventing dust and debris from interfering with your application.

- Masking Tape: Masking tape is useful for protecting areas of your workbench that you don’t want to finish, ensuring clean lines and a professional look. It can be especially helpful when applying multiple layers of finish or when you are working on specific features of the bench.

- Respirator or Mask: When working with finishes that emit fumes or dust, a respirator or mask is critical for protecting your respiratory health. Ensure that you choose a mask suitable for the type of finish you are using, particularly if it is solvent-based.

- Leveling Tool: Ensuring your workbench is perfectly level is vital for both functionality and aesthetics. A leveling tool, such as a spirit level, will help you verify that the surface is even before applying any finish, preventing uneven wear and appearance over time.

What Are the Key Steps for Ensuring a Smooth Finish?

To achieve the best finish for a workbench, it is essential to follow key steps that ensure a smooth and durable surface.

- Preparation: Properly preparing the surface is critical for achieving a smooth finish. This includes sanding the wood to eliminate imperfections, ensuring that the surface is clean and free of dust or debris, and checking for any rough edges that may need additional smoothing.

- Choosing the Right Finish: Selecting the appropriate finish for your workbench is vital for its functionality and appearance. Options include polyurethane, varnish, oil, or wax, each offering different levels of protection and aesthetic appeal. Consider the workbench’s intended use and the desired durability when making your choice.

- Application Technique: The method of application can significantly impact the final look of the finish. Techniques such as brushing, rolling, or spraying each have their advantages; for example, spraying can provide a smoother coat without brush marks, while brushing may allow for better control in detailed areas. Always apply thin, even coats to prevent drips and unevenness.

- Drying Time: Allowing sufficient drying time between coats is crucial for a professional-looking finish. Each type of finish has its own recommended drying times, and rushing this step can lead to smudges or a compromised surface. Be patient and ensure each layer is completely dry before applying the next.

- Final Sanding and Buffing: Once the final coat has dried, lightly sanding the surface with fine-grit sandpaper can enhance the smoothness. After sanding, buffing with a soft cloth will help to bring out the shine and ensure an even finish across the entire surface.